skip to main |

skip to sidebar

Each year, The Old Locomotive Committee (OLCO) has an event, called 'Lionsmeet', for live steam models of the 'Lion' locomotive and similar models of designs up to around 1850. In 2019, the event was held on Saturday, 17th August at the Littledown Park track of the Bournemouth & District Society of Model Engineers (B&DSME).

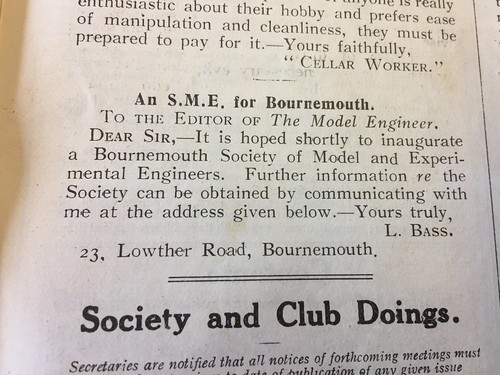

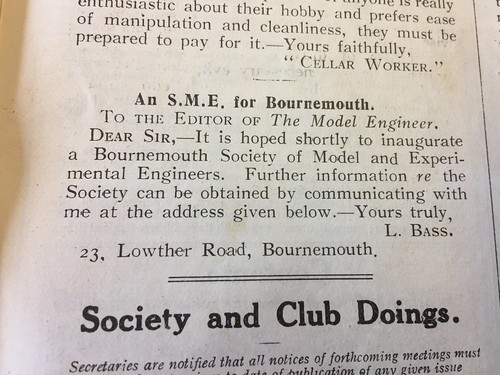

B&DSME has a long history during which it has operated on a number of sites as outlined on their website here. The Society was founded in 1924, as shown below.

Letter published in the Model Engineer & Electrician magazine on the 13th March 1924 announcing the inauguration of the Bournemouth society(Photo: B&DSME).

The present Littledown Park track was opened in 2004 in a popular Bournemouth park which incorporates a leisure centre. The part is described on Bournemouth Council's website here. The park features an attractive lake area, home to numerous ducks and a rather tame heron.

Lionsmeet 2019: Littledown Park features an attractive lake area with ducks and a rather tame heron.

The weather during the previous few days had been very wet in most of England but improved on the day of 'Lionsmeet', which proved dry and warm. On my arrival at the B&DSME Clubhouse, I was welcomed by host club members and my friends from OLCO. I was rapidly furnished with a cup of tea and, throughout the day, the host club were very solicitous regarding the welfare of their visitors.

Initially, the activity was centred around the multiple, elevated steaming bays outside the clubhouse as various 'Lion' models were steamed.

Lionsmeet 2019 Bournemouth: Andrew Neish and Adrian Banks chat as 'Thunderbolt' "brews up".

Lionsmeet 2019 Bournemouth: View of the Steaming Bays and traverser tracks.

An elevated traverser transfers locomotives between the steaming bays and a spur line leading to the running line. There is also a siding alongside the clubhouse to facilitate moving larger locomotives between road vehicles and the steaming bays. The traverser also serves two single road, covered carriage sheds which are almost invisible, situated close to the park boundary and hidden by bushes.

Lionsmeet 2019 Bournemouth: View of traverser and entrance to second carriage shed.

The traverser also gives access to a turntable. Although running on the main line is normally in a clockwise direction, I was told that periodically anti-clockwise running is adopted, to even out flange wear.

Lionsmeet 2019 Bournemouth: View of the Turntable. The carriages are standing on the spur line from the traverser to the running line.

The 1760 feet long continuous running line is situated in a pleasant wooded area close to the park boundary, and has a conventional 'dog bone' shape with two long, parallel sections joined at each end by 57 feet radius return loops. A station, named Bankside, is provided on the return loop near the clubhouse for loading and unloading passengers.

Lionsmeet 2019: View showing part of return loop at clubhouse end of line, the two parallel straight sections through the trees and the park boundary in the background.

The running line is supported on pre-cast concrete beams each 4 metres long, using just four different types (straight, curved with cant, left-hand transition, right-hand transition). The 4-rail multi-gauge track caters for 3½", 5" and 7¼" gauges. The track was pre-assembled into 3 metre long panels using 1kg/m steel flat-bottom rail profile, mounted on jig-drilled sleepers sawn from recycled plastic plank. The 'About' tab of the B&DSME website here has a lot more information about the track and its construction.

Lionsmeet 2019 Bournemouth: View of rail joints on the multi-gauge track.

A J Reynolds' 'Lion' was the first locomotive ready for running but John Dalton with his 7¼" gauge model and Adrian Banks with 'Thunderbolt' followed. Later, Nigel Way from the host club joined them, driving the 'Lion' owned by John Biss.

Once the traverser has transferred locomotives from the steaming bays to the spur line leading to the running line, a combination of hinging section on the spur and 'Bendy Beam' on the running line allow locomotives onto the main line. The 'Bendy Beam' is described on the B&DSME website here.

When electrical detection proves that the hinging sections and 'Bendy Beam' are correctly set for movements on the running line, the solenoid-operated lower-quadrant semaphore 'stop' signal facing Bankside station platform is automatically placed 'off'. Trains approaching Bankside station in a clockwise direction receive an advance warning from a distant signal. When the railway is not running, the signals are unplugged and stored in the wooden station building at Bankside. I was told that the signals can be installed in alternative locations when anti-clockwise running is adopted.

Lionsmeet 2019, Bournemouth: View looking north from station showing (L-R) spur line from steaming bay traverser, running line, holding siding.

The picture below shows Adrian Banks moving 'Thunderbolt' onto the running line.

Lionsmeet 2019 Bournemouth: Adrian Banks with 'Thunderbolt' moving from the spur line to the main line.

Once 'Thunderbolt' was on the running line, a member of the host club restored the hinged section and 'Bendy Beam' to allow continuous running to resume.

Lionsmeet 2019 Bournemouth: With Adrian Banks and 'Thunderbolt' on the main line, the 'Bendy Beam' is restored for main line running.

There was no competition running, so participants could exercise their steeds or chat with the members of the host club or OLCO during a relaxed day.

Lionsmeet 2019 Bournemouth: A J Reynolds was early onto the track with his 'Lion'.

Lionsmeet 2019 Bournemouth: John Dalton approaches the station with his 7¼" 'Lion'. Note the 'clear' distant signal.

Lionsmeet 2019, Bournemouth: Nigel Way, A J Reynolds and John Dalton lined-up at Bankside station with their models. Mains water with a portable bowser and buckets of coal are available here.

A splendid buffet luncheon was unveiled in the clubroom - a rather magnificent affair equipped with First Class seating obtained during the re-fit of railway coaches. Appropriately, the large colour display screen on the end wall was showing 'The Titfield Thunderbolt' on repeat.

Lionsmeet 2019: The clubroom, with ex-railway First Class seating.

The afternoon was particularly relaxing as the weather remained warm, presenting a good opportunity to study the interesting range of static exhibits on display.

Lionsmeet 2019: Bankside station on a warm afternoon.

Lionsmeet 2019, Bournemouth: (L-R) John Dalton, Andrew Neish and Peter Burton, B&DSME Chairman.

Lionsmeet 2019 Bournemouth: Harrye Frowen's 7¼"'Lion' was displayed by John Hawley.

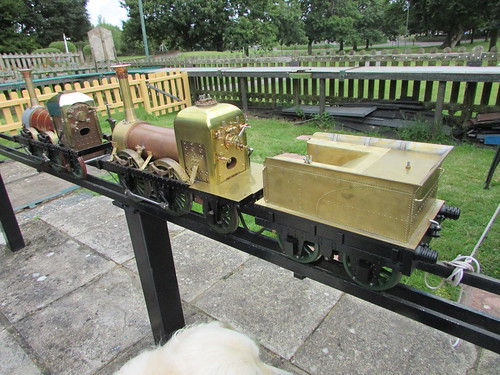

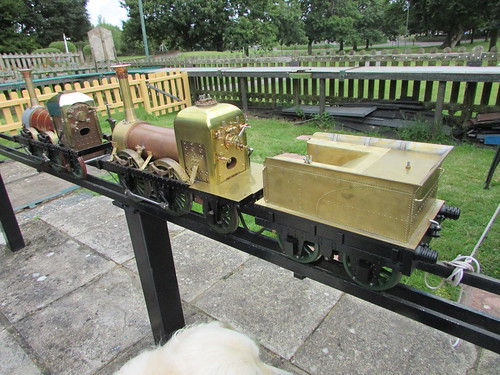

Lionsmeet 2019 Bournemouth: Two 'Lions' under construction.

Lionsmeet 2019 Bournemouth: John Biss's 'Lion' and train.

Other models by John Biss were also on show, including a rail-mounted hand-operated crane and an intriguing Pump-type Maintenance Trolley which is battery powerd and radio controlled!

Also on display was a completed model of 'Canterbury Lamb' and a rolling chassis I didn't identify for either a 2-2-0 or 0-2-2, together with a partial kit of parts for a 'Lion' offered for sale.

On an elevated storage siding in the clubhouse, I found another battery powered model called 'Sheddon Wheals' with a steam-outline superstructure painted blue and strangely reminiscent of a famous steam locomotive. There was also a nicely-executed six-coupled diesel outline locomotive named 'Littledown Castle' which I understand is petrol-engined. These last two locomotives exit the clubhouse via an opening hatch in the wall. When a bridging piece of track is correctly in place connecting the elevated storage siding to a nearby steaming bay outside, a 'moveable scotch' is automatically lowered to allow the locomotives to safely leave the storage siding.

There's also an out-and-back 16mm narrow-gauge garden railway on elevated baseboards, but it was not in use during 'Lionsmeet' and was protected by locked security covers.

All the above are illustrated in my album of pictures of Lionsmeet 2019 here.

It had been a most enjoyable day and John Brandrick, the OLCO Chairman, made a short address thanking the host club for their hospitality, enthusiastically endorsed by the OLCO members.

Lionsmeet 2019: Bournemouth: John Brandrick, OLCO Chairman, (with Dan) thanks B&DSME for hosting 'Lionsmeet' 2019.

Related posts on this website

All my posts about the Old Locomotive Committee can be found here. Most posts include links to my related pictures.

My pictures

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures from may be selected, viewed or downloaded, in various sizes, from the albums listed:-

Lionsmeet 2019.

All my 'OLCO' picture albums.

Events of Monday, 20th May 2019

After an enjoyable visit to Mandalay Railway Station in the morning (described here), we moved on to the serious business of the day, taking the much-improved Oriental Highway from Mandalay which climbs into the hills at Pyin Oo Lwin where Doctor Hla Tun was to make food donations at two orphanages. There are many posts in this blog regarding educational charitable work in Myanmar initiated by the 'Road to Mandalay Social Contribution'. You can find them all here or by selecting search label 'Education'.

In Pyin Oo Lwin, there is an orphanage for boys at Doe Pin and one for girls at Shwe Sin Minn. Both are supported on a regular basis by a Swiss charity, Enfants d'Ailleurs Foundation. The foundation remits funds to the Belmond Myanmar Foundation in London which releases them to Doctor Hla Tun who acts as a 'trusted intermediary' organising the actual food donations, normally two each year, to both orphanages. The Doctor arranges the formal handover, receiving the donation certificates issued by the orphanages on behalf of the donor organisation and providing photographs of the event.

My first visit to Doe Pin was in 2009 and I've been back from time to time ('Related posts' below lists posts describing these visits). The Abbott greeted us warmly, offering refreshments and Doctor Hla Tun checked the donated foodstuff laid out ready, checking the list of food and its cost recorded on a 'white board'.

Doe Pin Orphanage 20-May-2019, with the foodstuffs donated by Enfants d'Ailleurs Foundation on the left and listed on the 'white board'.

The Abbott issued the donation certificate to the Doctor and a number of photographs of the handover were made.

Doe Pin Orphanage 20-May-2019: Doctor Hla Tun receives the donation certificate issued by the orphanage, watched by a group of orphans.

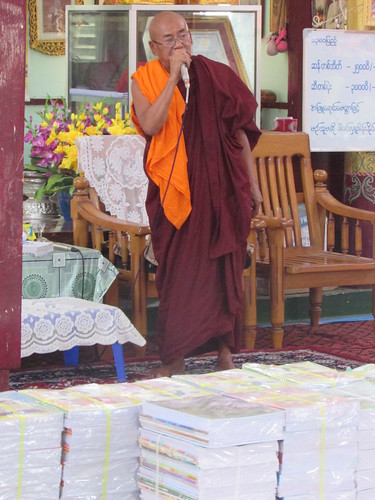

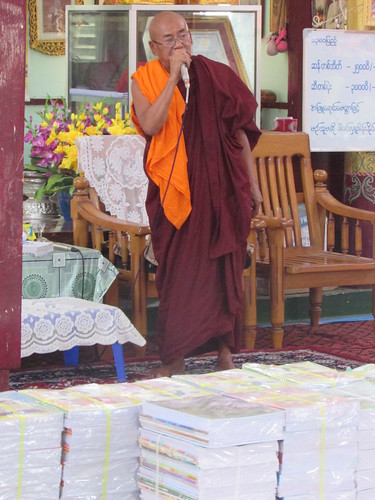

The Abbott then made a short address and, after some general conversation, we said 'good bye' and returned to our car.

Doe Pin Orphanage 20-May-2019: The Abbott makes a short address.

We drove through the town of Pyin Oo Lwin to Shwe Sin Minn orphanage founded by two sisters in 1999. My first visit was in 2011 when building work was in progress to expand the accommodation. I returned in 2013 to find another extension being constructed ('Related posts' below lists posts describing these visits). Arriving in 2019, I found another major new building under construction.

Shwe Sin Minn orphanage, Mandalay, 2019: New building under construction, given by a Taiwanese donor.

The food donated by Enfants d'Ailleurs Foundation was already laid out at the rear of the assembly hall, with the orphans sitting on the floor in the remaining space.

Shwe Sin Minn orphanage, Mandalay, 2019: Orphans gathered in front of donated sacks of rice. The 'white board' in the background lists the donated foodstuff.

The Head Nun presented the donation certificate confirming the foodstuffs received to Doctor Hla Tun.

Shwe Sin Minn orphanage, Mandalay, 2019: Doctor Hla Tun receives the donation certificate issued by the orphanage from the Head Nun.

The Head Nun then invited Doctor Hla Tun to make a short address to the assembled children.

Shwe Sin Minn orphanage, Mandalay, 2019: Doctor Hla Tun made a short address to the assembled orphans, watched by the head nun.

Finally, all the orphans moved outside for a group photograph.

Shwe Sin Minn orphanage, Mandalay, 2019: Orphans pose for a group photograph.

Having completed the formal donations at the two orphanages, we set off by car to return to Mandalay, stopping on the outskirts of Pyin Oo Lwin at a long line of roadside vendors. The area is well-known for strawberries, other fruit and various local wines. Doctor Hla Tun made some purchases to take back to his home in Yangon on the following day then we continued on the Oriental Highway to Mandalay, slowly making our way through the heavy traffic of the city to my hotel. Doctor Hla Tun had made his own arrangements for accommodation that night but insisted that the following morning we would travel to Mandalay Airport together where he would take a flight to Yangon and I would start my long journey home via Bangkok.

My friend Ko Hlaing and his young daughter Sandy had arranged to visit me at the Hilton Hotel in the evening. They didn't want a meal so we just went to my room for a chat and ordered soft drinks. Both speak good English making things easier for me and I really enjoyed spending a little time with them both since it had been around 18 months I'd seen them (that visit is described here).

Mandalay, 2019: Ko Hlaing and his daughter Sandy.

The visit concluded with Sandy and I going for a walk around the outdoor swimming pool. Although it was dark, the swimming pool area was well-lit, producing some dramatic lighting effects. There was time for one group picture in Reception before we finally said our 'good byes'.

Mandalay, 2019: Ko Hlaing, Sandy and Jan.

Related posts on this website

This is one of a series of posts describing my 14th visit to Myanmar. The post Return to Burma is the first post in the series.

Clicking on the 'Next report' link displays the post describing the next events. In this way, you may read about the trip in sequence.

Next report

Alternately, clicking on the 'All my Burma 2019 reports' link displays all the posts on this trip in reverse date-of-posting order.

All my Burma 2019 reports.

You can find all the posts about education support here or by selecting search label 'Education'.

The following posts include references to Doe Pin or Shwe Sin Minn:-

Visit to an Orphanage, Myanmar (Doe Pin) 2009

Three Orphanages 2011

Three Orphanages Revisited 2012

Support for Orphanages in Myanmar 2013

Maymyo 2013

News from Burma - Educational Support 2014

Two Orphanages and a Monastery 2018

My pictures

My pictures showing this part of the trip are in the albums:-

Hilton Hotel, Mandalay.

Burma 2019.

Doe Pin Orphanage 20-May-2019.

Shwe Sin Minn Orphanage 20-May-2019.

All my general pictures on this trip are in the collection of albums also called Burma 2019

[Link to 'Next report' added 5-Nov-2020]

I briefly described oiling 5542 in the earlier post On the Footplate but decided to go into a bit more detail so in the post Preparing 5542 (part 1) I started to describe the preparation of the locomotive. This article, Part 2, concludes the description.

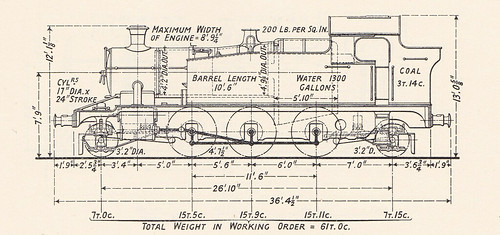

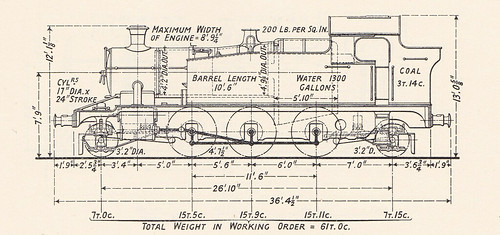

Layout of Locomotive

"4575" Class (Railway Publishing Co. Ltd. 1938)

Click for larger view.

In Part 1, I described oiling the motion accessible from outside of the engine at ground level. Attending to the inside motion requires the locomotive to be over an inspection pit giving access underneath the engine and allowing climbing up underneath the boiler between the frames. It doesn't matter what order oiling points are attended to but some sort of routine is necessary to ensure none are overlooked. Before disappearing into the pit, a suitable oil feeder, oil bottle of Motion Oil to allow replenishment of the feeder and the vital 'wiper' (a rag to remove any surplus oil) should be positioned in the pit or alongside the engine within reach of somebody working in the pit. This avoids having to either climb out of the pit part way through oiling to obtain supplies or shouting to your mate for assistance.

5542 has a pony truck at each end and, as you enter the pit, the oil fillers for the underkeeps on the pony truck axleboxes at that end face you as a reminder to check levels and periodically use a siphon to remove any water (which sinks to the bottom of the axlebox, being denser than the oil).

5542: Trailing truck, RH axlebox.

Most locomotives have an extensive system of rods and transverse shafts a few inches above rail level to allow all the brake shoes to be operated from a single power brake cylinder. In 5542 it's a steam brake cylinder mounted under the cab. Other British designs may use one (or two) vacuum brake cylinders and, particularly on steam locomotives used overseas, the power brake cylinder may be operated from pressurised air. Then, depending upon the design, there are additional obstructions from the suspension and various pipes. The chassis for the pony trucks on 5542 have to be ducked under, whichever end you approach from. Since 5542 also has mechanical linkages for remote control of the regulator when working 'Push-pull' or 'Auto' trains, there are also additional shafts and bell cranks to be avoided.

When moving around in the pit, it's necessary to bend down to avoid a nasty crack from contact with all this old iron. Traditionally, enginemen wore flat caps or the 'greasetop' hat during preparation, neither of which offers much protection against impacts to the head. A complication at Shackerstone is that the pit is not as deep as most pits, so a particularly hunched-up pose is required.

This rather-ape-like stance puts you at about the right level for attending to the underkeeps of the six coupled wheels which are provided with a short 'elbow' closed with a cork allowing any water to be removed with a siphon.

The next problem is to decide where to climb up into the space underneath the boiler not occupied by the inside motion or the various 'additional obstructions', to allow oil to be applied to the numerous oiling points. Depending upon stature and fitness, different people may adopt different solutions. I generally clamber up first ahead of the trailing coupled axle and then to the rear of the leading coupled axle.

A wooden stool with a single step is dragged into position in the pit ahead of the trailing coupled axle. This task is often harder than it sounds as the preparation pit is also used for disposal, so there is usually a pile of ash just where you'd like to set the stool. Feeder and oil bottle are then placed where they can be reached after you've ascended. Climbing onto the stool then puts the trailing coupled axle at about waist height so I then hoist myself up so as to sit on the axle, facing the driving axle with its four eccentrics. Leaning forward, I can first top-up the four eccentrics and then, reaching up left and right, attend to the four-feed oilboxes mounted on the inside of the main frames. The four tail trimmings in each oilbox feed a driving axlebox, via flexible hoses (2 for hornguides, 2 for axlebox) which allow for the up-and-down motion of the axlebox in the hornguides.

5542: Driving axle showing RH eccentrics.

5542: Four-feed oilbox mounted on the inside of the right main frame for Right Driving Wheel.

Having completed this part of the oiling, it's time to climb down into the pit and re-position the wooden stool, feeder and oil bottle to allow me to climb up again to sit this time on the leading coupled axle, facing rearwards, allowing the rest of the Link Motion to be oiled. Following Churchward's example, Collett provided comprehensive arrangements for keeping the Link Motion lubricated. There's a fair bit of stretching (and grunting) to reach all the corks and top-up the oil reservoirs. Then, reaching left and right, the two four-feed oilboxes mounted on the inside of the main frames which serve the leading coupled axleboxes are dealt with. The four tail trimmings in each oilbox feed a coupled axlebox, via flexible hoses

5542: Link motion for right-hand cylinder.

5542: Four-feed oilbox mounted on the inside of the right main frame for Right Leading Coupled Wheel.

5542: Four-feed oilbox mounted on the inside of the right main frame for Right Leading Coupled Wheel.

The last oiling points here are on the inner arms of the LH and RH Rocking Shafts, reached by twisting round.

5542: Upper end of RH Intermediate Valve Rod, showing connection to inner arm of Rocking Shaft.

With the rather unpleasant 'inside' examination and oiling complete, it's time to exit the pit and climb up onto the framing at the front of the engine to deal with two rocking shaft oil pots, two additional oil pots and the vacuum pump oil reservoir on the right side of the engine. The vacuum pump reservoir generally uses a steam oil and paraffin mix. On the left side of the engine there is no vacuum pump oil pot but there are two oil pots for the rocking shaft plus one additional oil pot. In Part 1, in looking at the outside motion, we'd already seen that the oiling points differ on the two sides of the engine because of the design of the slide bars and crossheads. Just below the bottom of the smokebox door, on the boiler centreline, there's a single footstep to assist the crew in reaching up to place a lamp on the top lamp iron when required. This position is always referred to as the 'chimney' but, of course, the lamp iron is actually fixed to the smokebox. Almost hidden underneath this footstep is another oil box requiring attention.

5542: View of framing on right-hand side of boiler, ahead of side-tank.

In Part 1, the Sight Feed Lubricator using steam oil is described by reference to an earlier post '5542 at the Battlefield Line'. There are also two 4-way oil boxes, in the cab fixed to the inside of the left and right side tanks at high level. The four tail trimmings in each oilbox feed a the left and right coupled wheel axleboxes via copper pipes (2 for hornguides, 2 for axlebox).

5542: 4-feed oil box mounted on the left of the cab (actually on the side tank) feeding the left trailing coupled wheel. A second, similar oil box is mounted at a lower level.

Finally, there's a low level oilbox only on the fireman's side of the cab.

5542: 4-feed oil box mounted on the left of the cab (actually on the side tank) mounted at a low level. The round 'hatch' on the left of the picture provides access to the sidetank.

Related posts on this website

Preparing 5542 (part 1).

There are also a number of other posts with technical content about working on 5542:-

GWR 'Light Prairie' 5542 (22-Aug-2010)

On the Footplate (5-Dec-2017)

Santa Specials at the Battlefield Line 2017 (19-Dec-2017)

5542 at the Battlefield Line (28-Aug-2018)

Battlefield Line 'Family Fun Weekend' (3-Sep-2018)

5542 at the Battlefield Line in 2019 (30-Jul-2019)

To see all my posts about the Battlefield Line, select Label 'Battlefield Line' or click here.

To see all posts with Mutual Improvement Class content, select label 'MIC'or click here or look at the index at Mutual Improvement Classes (2).

My photograph albums

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures may be selected, viewed or downloaded, in various sizes, from the album listed:-

5542 GWR Locomotive