skip to main |

skip to sidebar

Some years ago, when I started my travels overseas, I was frequently horrified with the risk of 'trips, slips or falls' to which pedestrians were exposed. At the time, I considered that the United Kingdom handled these risks better. After the world-wide economic problems of 2008, my country entered a period of 'austerity' and funding for repairs to roads and pavements came under pressure. Despite continued emphasis on 'Health and Safety', I feel that my country has elevated itself to a position amongst the world leaders in terms of unrectified hazards to road users.

Pothole in Sandy Lane, Brewood

Part of the reason for these problems in the U.K. is the common practice of distributing services underground. Mains water, Gas, Electricity and Telecommunications, together with Drains for Surface Water and Foul Water (sewage) are typically buried in the ground, usually underneath the surface of a road. This is fine until repairs or alterations to any of the services are required, necessitating removing the road surface and digging-up the sub-soil until the required service is exposed. The obstruction of the carriageway creates traffic management problems, often addressed by traffic control using temporary traffic lights. The presence of the excavation, often a couple of metres in depth, also presents a danger to pedestrians, often dealt with by some form of temporary fencing. Requirements for signage to alert both pedestrians and vehicles to the temporary works further complicate matters.

Brewood Village: Temporary traffic lights and signage during connection of buried services to a house extension in Sandy Lane.

In the United Kingdom, I think mains water and drains are invariably buried. The same applies to domestic mains gas supplies but I was interested to discover (on my trip Caspian Odyssey) that in Armenia and neighbouring Georgia, gas is distributed above ground because volcanic activity can cause sufficient ground movement to damage buried pipework. In these countries, this seemed to result in an unsightly and sometimes rather'Heath-Robinson' arrangement of pipes, elbows and supporting brackets.

Brewood Village: Directly-buried underground services during connection to new houses in Sandy Lane. Note the printed identification tapes laid on top of the gas main (left) and water main (right).

Both electricity and telecommunications cables are sometimes carried above ground.

An underground multi-pair telecommmunications cable feeds a telegraph pole from where subscribers are connected by overhead 'drop-wires'.

Indeed, when telephones started to proliferate, they were initially invariably fed by two (less commonly, one) bare copper wires carried on ceramic insulators on the cross arms of 'telegraph poles'. In a built-up area, the number of circuits was visually intrusive but at least readily accessible for maintenance (if you had a head for heights).

'Openreach' Lineman working on a British Telecom Distribution Pole in Victoria Road, New Brighton.

As the idea of generating mains electricity in one place and distributing it to consumers over a wider area grew, it was logical to copy the transmission methods used for telephones by using copper wires carried on porcelain insulators on wooden poles.

Three-phase 'Delta' connected overhead electricity transmission line on wooden pole, showing connection to multi-core insulated cable leading to a transformer at ground level. The pole is stayed by two stranded galvanised steel guy wires, each incorporating an 'egg' insulator.

A 3-phase electricity supply being distributed by four insulated cables twisted together, carried overhead on wooden poles. A teed connection to a consumer is carried on four separate, parallel wires. Overhead 'drop-wires' for telephones are fed from an underground cable via a plastic terminal box. Note the 'Egg' insulator in the stranded galvanised steel guy wire.

As technology developed better electrical insulating techniques, it became possible to manufacture electrical cables where one tough, impervious sheath embraced a number of separate electrical conductors. For telephony, there might be many thin conductors capable of carrying a number of separate circuits. For power transmission, a small number of thick conductors were common. These cables could then be buried, removing the need for a series of poles to support the service.

Particularly for distributing telephone circuits in a built-up area, a large number of circuits would leave the exchange but then split to serve different groups of suppliers. This could conveniently be done by bringing the exchange cable into an accessible underground chamber where other cables could be interconnected, usually via an above-ground terminal cabinet allowing changes to the circuits provided and a convenient location for testing when faults occurred.

Termination chamber, Market Place, Brewood (during replacement of lid frame).

Power distribution often used inaccessible, buried joints to 'tee' power to individual users. In the 1950s, the Victorian house I was living in was finally connected to mains electricity (we'd previously only had mains water and gas). I was fascinated as the pavement was dug-up, the electric cable passing the house - the 'street main'- was located and the lead outer sheath removed to expose the individual three live phases, the neutral and (I think) the protective earth, each with its own electrical insulation. With what seemed to me very inadequate protective clothing and a few rubber mats to line the excavation, the jointer calmly attached the spur cable which would feed the house to one of the three phases, the neutral and the protective earth. Each joint was very carefully made and soldered for reliability. I presume some insulation was applied but I can't remember details. The remainder of the process involved making-good the sheath of the main cable and sealing the new spur cable so as to prevent the ingress of moisture. The joint closure was two pre-formed sheets of lead about two feet long, one fitted under the new joint, one on top so as to embrace the main cable, fitting snugly around the street main at each end of the joint and around the new spur cable. The two halves of the joint closure were held tightly together by bending over interlocking tabs at the edge of each sheet of lead before carefully heating the lead with a blowlamp and 'wiping' it with moleskin until a continuous, waterproof lead sheath had been created along the 'street main' and new spur cable.

Pictures around Brewood Village

The following album includes some examples of local services infrastructure:-

Brewood Village

Although Peak Rail ran a reduced service in February and March 2019, my first driving turn at Peak Rail in 2019 was Sunday, 7th April. I also describe a turn on Easter Saturday. The year then continued following a similar pattern.

Sunday, 7th April 2019

No. 72 on an 'Up' train pauses at Darley Dale on 25th March 2018.

The popular 'Austerity' 0-6-0 saddle tank No.72 which had worked the services during 2018, usually top-and-tailed with a main-line diesel (D8 'Penyghent'), had been retained as the steam motive power in 2019. In the morning, Mike S. was fireman with C. Ward taking over in the afternoon. Colin D. was cleaner all day and it was a merry footplate.

In the morning, Mike and I came off-shed at 08:30, in order to collect our driving experience candidate from Rowsley Station at 08:45, giving him two hours on the footplate. This time was divided between familiarisation with the locomotive and its controls, driving between Rowsley and the Up Home signal at Church Lane, operating Rowsley South Ground Frame to allow shunting movements to the loading dock at the north end of Rowsley Yard (where our driver was met by his wife and two children) and a little practice firing.

Apart from the 'pole' reverser, which was unreasonably stiff to move following maintenance work, the engine performed well.

Easter Saturday, 20th April 2019

Once again, No. 72 was the motive power. Robin S. was fireman all day. He'd stayed 'on site' overnight and booked on very early (04:15) so we were ready to come off shed nice and early and we sat in the platform at Rowsley, waiting for our driving experience candidate who enjoyed a 1-hour experience course, followed by a footplate ride on the first service train to Matlock Town.

The weather was bright and warm and we had plenty of passengers on all the trains. When we arrived back at Rowsley after the fourth round trip, we were informed that we'd started a small lineside fire. On that return trip (when we were being 'towed' by 'Penyghent') I'd seen a couple of people standing on the public footpath adjacent to the line, apparently looking at the track, but I'd spotted nothing untoward. Keen to ensure that any embers were fully extinguished, the Guard recruited help, loaded at least two five gallon drums of water into the Guard's compartment and we arranged to stop at the incident on our last trip to Matlock to ensure the fire was out. We stopped as planned and the Guard made a thorough job of dousing the area with water before completing the trip. Only a tiny burnt area was apparent and I joked to the Guard that he could have spit on on it to make it safe but, in very dry weather, lineside fires can be very serious and preserved railways may ban the use of steam locomotives during high-risk conditions. I described another lineside fire on the Battlefield Line in the post here.

Peak Rail 2019: A small lineside fire.

Related Posts on this Website

The 'Austerity' 0-6-0ST locomotive.

My pictures

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures may be selected, viewed or downloaded, in various sizes. Within each album, photographs are normally arranged by date taken.

No. 72 - Austerity Tank.

Peak Rail 2019.

All my Peak Rail Albums.

On previous visits to the Battlefield Line, 'Light Prairie' 5542 has always been a popular and reliable performer. She was welcomed back again in March 2019 and below are brief notes on a few 'turns' I had.

The timetable

The timings for the 2019 weekend 'Green Timetable' of five return workings between Shackerstone-Market Bosworth-Shenton were as follows:-

| Shackerstone Dep |

11:00 |

12:15 |

13:45 |

15:00 |

16:15 |

| Market Bosworth Arr |

- |

- |

- |

- |

- |

| Market Bosworth Dep |

11:12 |

12:27 |

13:57 |

15:12 |

16:27 |

| Shenton Arr |

11:20 |

12:35 |

14:05 |

15:20 |

16:35 |

| Shenton Dep |

11:35 |

12:50 |

14:20 |

15:35 |

16:50 |

| Market Bosworth Arr |

- |

- |

- |

- |

- |

| Market Bosworth Dep |

11:45 |

13:00 |

14:30 |

15:45 |

17:00 |

| Shackerstone Arr |

11:55 |

13:10 |

14:40 |

15:55 |

17:10 |

Because of a major programme of track laying in progress at Market Bosworth, to create a passing loop, the pedestrian level crossing at the Shenton end of the Market Bosworth station was closed at the beginning of the season. Since this was the only public access to the single platform, 'early season' trains were temporarily not calling at Market Bosworth. Once the main line turnout had been completed, the pedestrian level crossing was reinstated and, later in the year, trains resumed the intermediate stop at Market Bosworth. The timetable does not specify arrival times at Market Bosworth in either direction but crews attempt to arrive around 2 minutes before booked departure, to allow a reasonable time for passengers to leave and join the train.

Mothering Sunday: 31st March 2019

I was driver on 5542's second day in traffic during the 2019 season on Sunday, 31st March (Mothering Sunday) when she carried out five round trips from Shackerstone to Shenton, two of which were special Mothering Sunday Afternoon Cream Tea trains. The married couple of Rod and Tracy Tye shared the firing duties.

Although Market Bosworth station was closed in March 2019, as explained above, we made a couple of Special Stops there at the request of the Guard for commercial purposes.

We had an enjoyable day without problems.

"Mother's Day" Afternoon Cream Tea at the Battlefield Line (Photo: Graeme Watkins).

5542, with Jan driving, passing Permanent Way gang at Market Bosworth on 31st March 2019 (Photo: Adrian Lock).

Easter Bank Holiday Monday: 22nd April 2019

I was back on 5542 with Ritchie Marcus firing, carrying out the Green Timetable shown above. The weather was kind, there were plenty of passengers and a holiday atmosphere prevailed. The engine seemed to enter into the spirit and steamed "like a witch".

5224 at the Battlefield Line: Ritchie on the footplate

I did a little firing myself that day and was pleased with the results using the technique of "getting a good back" on the sloping grate. Welsh coal is very friable (allegedly why the Great Western had no automated coaling plants) so there was plenty of dust blowing around, even with liberal use of the 'slacker' (coal watering pipe) but otherwise there were no problems and Ritchie and I agreed we'd had a good, although tiring, day.

5224 at the Battlefield Line: Back in the shed after a good day.

A Difficult Day

Not all 'turns' are text-book. On Sunday, 28th April I had a rather trying day which eventually became good but was particularly exhausting. The problems started as soon as I signed-on at 05:45: There was no fireman. I had not been advised who was rostered to fire so I decided to start lighting-up myself. At 06:30 a rather shame-faced fireman arrived saying he'd overslept the alarm. Although I knew him, I'd not worked with him on the footplate before but he seemed confident so I left him to finish lighting-up, stressing how little time we had because of the Gold Footplate Experience. With the fireman was a cleaner I'd not met before said he'd oiled 5542 a number of times before so I let him oil 'outside' while I went into the pit to oil 'inside'. I emerged from the pit around 07:30 plastered with ash and oil. To add to my woes, the electric pump in the pit couldn't be induced to work so I'd ended up splashing around in a few inches of oily, ashy water at the cab end of the pit but, fortunately, my boots remained fairly waterproof.

Returning to the footplate to see how matters were progressing, I was greeted by a nice little fire in the front of the box which would probably have steamed quite well in two or three hours but I pointed out we didn't have that long. Accompanied by the fireman and cleaner, I found more wood and started to spread the little fire with a fire-iron until the whole grate was covered with a better coal and wood fire. However, it had been cold in the night and there wasn't much heat left in the boiler so I wasn't very optimistic and went to warn Mark H. that we'd be late off-shed, to be told that our driving experience trainee and his family were already touring the Museum.

I returned to the shed to coax the fire and, to my surprise, we'd managed 20 pounds by nine o'clock. By the time I'd given our driving experience trainee a walk round the engine, we'd made about 60 pounds so I took the engine off-shed. It was about 09:10 when we carefully left light engine but I was still worried that pressure wasn't building as I expected (it wouldn't rise above 160 pounds) and the fireman seemed unsure how to proceed. I knew the grate was clean when we started and I'd warned him not to get the front of the fire too thick - that had seemed to promote clinker on the sloping grate of this engine in the past. The coal seemed the same as earlier in the year (Ffos-y-Fran opencast) although there did seem a particularly high proportion of slack in the bunker. However, no arrangements had apparently been made for re-coaling and the fireman remained confident so we pressed on. Light engine, of course, 160 pounds was no problem.

In the cutting between Market Bosworth and Shenton we found a fairly large tree across the track (it had been a rough, windy night). We stopped and tried to pull it clear. It was multi-stemmed and some of the smaller branches came away but the main root, about six inches diameter, was still firmly attached. We managed to bend the branches forward , slide the engine past and continue to Shenton. On the return, we tried again to remove the tree but decided we'd need a hand saw to cut the trunk so we bent the branches the other way and slid past again.

We stopped at Shackerstone box to report to the signalman and he lent us a small saw. To be on the safe side, we decided we'd take water before coupling onto the train. A number of members of our driving experience trainee's family were to travel on the round trip driven by the trainee. Whilst the fireman and cleaner took water, I 'fettled the fire' and managed to get the valves lifting but as soon as we started away the pressure collapsed again, despite my guidance to the fireman. Fireman need to anticipate and not relax as soon as the boiler pressure starts to increase. The amount of slack in the bunker didn't help. Although it burns, if you put too much in one place, it acts like sand and I could see that the back of the fire was tending to become a black 'tump' not steaming properly, even after a the fireman gave it a 'stir' with the fire iron.

We stopped at the fallen tree and the fireman and our driving experience trainee used the saw to cut the tree root and drag the remains clear. I decided to stay on the engine and coax the fire to a better state. Whilst running round the coaches at Shenton, I again did what I could with the fire but although I could get it blowing off and fill the boiler whilst at a stand, on the road the pressure still tended to drop to around 160.

However, we got back safely to Shackerstone and I was asked to present the certificate to our driving experience trainee, who had performed very well.

Jan presents the certificate after a Gold Experience (Photo: Mark Heseltine).

We ran round and watered (I fettled the fire) then backed onto the train (more fettling) and we set off with the 11:00 departure rather late, having agreed with Mark's suggestion to follow the late-running 11:00 service by the 13:45 departure, cancelling the 12:15 advertised round trip altogether. I was a lot happier with the state of the fire as we set off with the delayed 11:00 but the fireman still wasn't reacting quickly enough and we lost pressure 'on the road'. At Shenton, I had another go at the fire. The fireman said he was experienced with 'Panniers' 6412 and 6430 which we'd used on the 2018 'Santa Specials' (there's a brief report on the 'Santa Trains' here) but said he couldn't figure out 5542. Well, I was a bit puzzled with our problems, too. The amount of slack in the coal certainly didn't help and the fireman had to go 'bunker diving' quite frequently to sort out more lumps. Although the fireman was willing and keen as mustard, his relative inexperience meant that on the return journey, between Market Bosworth and Shackerstone, I realised that we were going to have to 'stop for a blow-up'. We came to a stand near Carlton Bridge with the brakes dragging. After less than ten minutes, we carried on and arrived safely at Shackerstone, ran round and watered, ready for the 13:45. Whilst the fireman and cleaner had a quick lunch, I stayed on the engine trying to get the fire 'right'. There was very little clinkering, just black slow-to-burn areas.

We set off with the 13:45 and things definitely seemed better. Although pressure came down, it didn't continue to collapse and the fireman seemed to 'get it' and fired more promptly. At last, pressure recovered in the station stops and when the valves lifted, it encouraged both of us. I reduced my physical interventions in firing as the fireman seemed to be getting better at judging the necessary firing rate. When the engine was working, the fire was now white-hot. The cleaner did all the uncoupling and coupling, allowing the fireman to concentrate on finding more lumps and managing the boiler.

I was glad we'd 'dropped' the 12:15 round trip, because by the time we set off on the 15:00 departure we were already fairly tired . The engine continued to steam as you'd expect from a 'Swindon' engine but, despite regularly sweeping the footplate and using the 'slacker', the wind was whisking clouds of coal dust around. But we were all relieved that we'd finally got a 'good steamer'. We got back to Shackerstone within a few minutes of 'right time' and ran round, taking water for the last time.

I was rather worried as to just how empty the bunker had become and most of what remained was slack. The fireman remained optimistic and the last trip to Shenton was done in fine style with the safety valve starting to 'sizzle' each time the regulator was closed. On the way back, the fireman realised that the fuel situation meant that he could no longer recover the pressure as it started to fall. I came back in a leisurely fashion, one eye fixed on the boiler pressure gauge and I noticed that, this time, the fireman was paying careful attention to the gauge too. Of course, my main concern was keeping the vacuum brakes released and our final arrival in Shackerstone with almost 140 pounds on the clock was a great relief. We'd half a glass of water remaining so I was sure we'd be alright. We raked through the fire outside the shed, pushing good fire towards the tubeplate. There was very little clinker. We stabled inside the shed and had no problems filling the boiler well above the top nut. We all agreed it had been a good day but, oh, it was hard work.

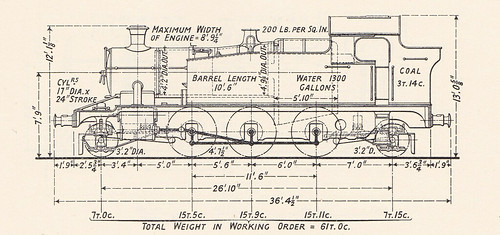

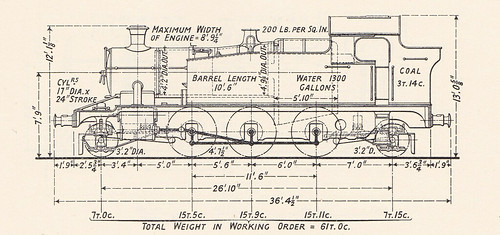

"4575" Class (Railway Publishing Co. Ltd. 1938).

Related Posts on this Website

GWR 'Light Prairie' 5542 (22-Aug-2010).

On the Footplate (5-Dec-2017).

Preparing 5542 (part 1) (14-Sep-2018).

5542 at the Battlefield Line(28-Aug-2018).

Battlefield Line 'Family Fun Weekend' (3-Sep-2018).

Battlefield Line Steam Gala 2018 (Part 2) (4-Jan-2019).

My pictures

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures may be selected, viewed or downloaded, in various sizes, from the albums below:-

5542 GWR Locomotive.

Battlefield Line 2019.

Monday, 20th May 2019

Observant readers may have noticed a certain interest in railways on my part and that includes railways in Myanmar. On previous visits to Mandalay, I had found out as much as I could about Mandalay railway station and its environs by observation from public areas. The station is a modern, multi-storey reinforced concrete building towering over the railway tracks.

Mandalay Station, 2015. The building incorporates the Hotel Marvel.

The entrance is past a row of imposing columns via granite-clad steps. The effect is somewhat diminished since some of the steps have been damaged for some time but remain unrepaired.

The imposing entrance to Mandalay Station in 2014.

On previous surveys, I'd concluded that the station was controlled from a Power Signal Box at the north end of the station, so I'd long harboured the ambition of making a closer inspection. I'd discovered that the signal box is often referred to as 'Mandalay Tower', borrowing the American term for a signalling control.

Mandalay Power Signal Box ('Mandalay Tower') in 2014.

Mandalay Power Signal Box ('Mandalay Tower') in 2014.

Doctor Hla Tun, whilst not sharing my interest in railways and railway signalling, had very kindly used his contacts to arrange an official visit to Mandalay Power Signal Box on Monday, 20th May. So, after delivering me safely to the Hilton Hotel on Sunday, the Doctor remained in the area overnight (I believe he visited the Captain of the 'Road to Mandalay' river cruise ship which was docked at nearby Shwe Kyet Yet awaiting the start of the next cruise season). On Monday morning, I took breakfast at the Hilton Hotel and the Doctor then collected me for our visit to 'Mandalay Tower'.

Mandalay, 2019: Breakfast at the Hilton Hotel.

We drove through the crowded streets of Mandalay to the station and made ourselves known to the Station Master's staff. We were then quickly welcomed into the Station Master's Office. After initial explanations by the Doctor, the Station Master proudly displayed a magnificent wood carving depicting the first railway locomotive to operate in Burma.

Visit to Mandalay Tower: Mandalay Station Master in his Office with a magnificent wood carving depicting the first railway locomotive to operate in Burma.

The artist had produced a reasonable impression of what must have been an unfamiliar object. The original locomotive is preserved and I photographed it back in 2013, plinthed inside the entrance to Naypyidaw Station, during a visit described here.

Locomotive A.01 displayed at Naypyidaw Station - a 2-4-0T built by Dubs & Co. in Glasgow, put into service 1-May-1877. Weight: 17.65 tons. Tractive Effort: 3857 lbs.

Adjacent to the carving, a number of framed photographs showing the previous station building caught my eye, as I couldn't recall having previously seen a picture of the original station arrangements.

Visit to Mandalay Tower: Old photograph of Mandalay Railway Station.

There was also the usual station signalling diagram on the wall, in this case a rather nicely framed version.

Mandalay Tower: Signalling diagram in Station Master's Office.

Click for larger version

The Station master then introduced us to a lady assistant, who conducted the Doctor and I along the platform to the north end of the station and then across the tracks to the ground floor entrance of the signalling building, a 1950s structure of reinforced concrete. Internally, two steep flights of wooden stairs led us up to the operating floor at the top, where we met the signalman and his assistant.

Mandalay Tower: The signalman and his assistant. The rear of the signalling console is in the foreground.

The 'welcoming committee' included the Signal Maintenance Technician and a Signalling Engineer, who were both keen to show me everything. I was particularly impressed when the Signal Engineer showed me an introductory manual, apparently put together by the railway, summarising the important features of the installation, with photographs. They allowed me to take pictures of this useful manual.

Mandalay Tower: Title Sheet of Introductory Manual.

The signalling control console itself was a 1957-vintage 'NX' panel made by Kyosan in Japan. An additional, rectangular control panel had been bolted to the top of the original console at some stage to provide extra controls. But what struck me forcibly was that the console, whilst old, was clean and had been carefully looked after. As far as I could judge, everything appeared to be functioning as originally designed which was testimony to the maintenance effort.

Mandalay Tower: NX Signalling Console (Photo: Myanma Railways).

I tried to quickly make a photographic record of everything and then the party moved downstairs to the relay room. The original equipment by Kyosan was in a suite of floor-mounted Relay Cases with hinged, glazed doors at the front showing the banks of plug-in relays inside. Again, the equipment was clean, properly secured against tampering and a credit to the maintenance staff.

Mandalay Tower: Floor-mounted Relay Cases by Kyosan.

In addition, there was a relay case with smaller Siemens signalling relays and arrangements for distribution of a.c. and d.c. power which included a large a.c. switchboard.

Mandalay Tower: A.C. Switchboard

All the points around the station were remotely operated by electric point machines and the Signal Engineer asked if I'd like to make a closer inspection. Of course, I said 'yes' so the whole party descended the wooden stairs and walked to a nearby point machine.

Mandalay Tower: Leaving Mandalay Tower to survey Electric Point Machines (L-R: Signal maintenance technician, Station Master, Station Master's lady assistant.

They removed the cover from the mechanism so that I could study the mechanism and then, using hand portable radio, instructed the signalman to operate the points so that I could observe the procedure. This example was a Kyosan 'Old' type which they said could take up to 10 seconds to complete its movement (although the example we looked at was much quicker).

Mandalay Tower: Kyosan Point Machine, Old Type.

They explained that the 'New' type Kyosan point machine takes only 4 seconds to complete its movement, demonstrating this on a second nearby point machine which was, indeed, significantly quicker.

Mandalay Tower: Kyosan Point Machine, New Type.

Whilst this was going on, the Station Pilot was waiting to carry out a shunting move, so we finished the demonstration to allow the shunting to continue.

Mandalay Tower: Locomotive DD.958, acting as Station Pilot, waiting to shunt, with the blue-painted station building in the background

Having thanked the staff from Mandalay Tower, we followed the Station Master back to the station building where he led us through the reception of the Marvel Hotel into an impressive meeting room where we chatted briefly. I was initially puzzled that the Station Master chose to sit up against one wall rather than in the central area, until Doctor Hla Tun explained that the chosen seat was directly under an air conditioning vent!

Mandalay Tower: Meeting room of Hotel Marvel.

Before we left, we'd been invited to briefly meet the Divisional Manager so we said 'good bye' to the Station Master and his lady assistant took us by lift to an upper floor of railway offices. But as we walked down the broad corridor to the Divisional Manager's Office, a member of staff explained that the Divisional Manager had had to go out unexpectedly. Recovering quickly, the lady assistant asked if I'd like to see the Train Control Office on the same corridor. That was an real bonus for me. An outer office led to an 'inner sanctum' where the Train Controller and his staff worked.

Visit to Mandalay Tower: Train Control Office viewed from the outer office.

Because of the heat, the train controller had partly disrobed and was not wearing his uniform white shirt with epaulettes. Somewhat embarrassed, he quickly corrected his dress. In front of him, on a sloping desk, was the manually-updated Train Graph, the master record of all train movements in the Mandalay Division so far that morning.

Visit to Mandalay Tower: Train Graph in Train Control Office.

All this activity relies on reports received and instructions issued using three VHF Radiotelephones on a desk adjacent to the train graph.

Visit to Mandalay Tower: VHF Radiotelephones providing communication with Station Masters and Signalmen in the Mandalay Division. The Train Graph is on the right

Visit to Mandalay Tower: VHF Radiotelephones providing communication with Station Masters and Signalmen in the Mandalay Division. The Train Graph is on the right

Of course, the train controller must have an intimate knowledge of the lines under his control and the walls of the office displayed a number of track diagrams of the Mandalay Division for reference. I quickly took pictures of as many as I could before we thanked the controller and left. Back on the ground floor, the lady assistant said that she had to resume her normal duties so, after an especially enjoyable and informative visit, we returned to our transport. Our activities during the rest of the day could hardly have been in more marked contrast with the morning. I'll tell you more next time.

Incidentally, the above post is supposed to be the 'non-technical' version and, as time permits, I hope that a more detailed report will appear.

Related posts on this website

This is one of a series of posts describing my 14th visit to Myanmar. The post Return to Burma is the first post in the series.

Clicking on the 'Next report' link displays the post describing the next events. In this way, you may read about the trip in sequence.

Next report.

Alternately, clicking on the 'All my Burma 2019 reports' link displays all the posts on this trip in reverse date-of-posting order.

All my Burma 2019 reports.

My pictures

My pictures showing this part of the trip are in the albums:-

Mandalay Tower.

Hilton Hotel, Mandalay.

Burma 2019.

All my general pictures on this trip are in the collection of albums also called Burma 2019

On Saturday, 13th July 2019, the Brewood Garden Party was held, for the seventh time, in the garden at Brewood Hall. The event is organised by 2nd Brewood Scouts, Brewood Parish Church and the informal group Friends of Brewood Hall. All of the work organising and running the event is carried out by volunteers.

Preparation

An organising committee representing the voluntary groups involved met a number of times in the months prior to the event to arrange the details. Publicity was displayed in the village and 'flyers' delivered to houses.

Setting Up

Starting on Wednesday, 10th July the tents, tables and chairs needed were ferried in over a number of trips using a car and trailer and erection of the main tents was carried out by Ian Morris and Gary Dunbar. On Friday evening erection of the smaller tents and arranging the seating areas was undertaken by the Scouts. An event of this nature, lasting just four hours, requires a lot of commitment from those involved but the Garden Party has established itself as a popular feature of village life.

Brewood Garden Party 2019: By late Friday evening, all the tents were erected.

On Saturday morning, volunteers arrived to complete the setting-up.

Brewood Garden Party 2019: Volunteers complete the setting-up on Saturday morning.

Brewood Garden Party 2019: Volunteers with a remarkable range of plants readying the Plants & Produce Stall on Saturday morning.

The Craft Tent featured the work of a number of talented people, including Fern Floating Fine Art, passing through Brewood on the Shropshire Union Canal and recruited by Ian Morris to appear alongside our established local artists and crafters.

Brewood Garden Party 2019: Crafters setting-up on Saturday morning.

Brewood Garden Party 2019: Crafters setting-up on Saturday morning.

Getting ready involved so many different tasks, I was worried that we'd not be ready for the published opening at noon but, somehow, it all came together in time.

The Event

With my friend Rita on the admissions gate, assisted by Peter, our visitors started to arrive, slowly at first, then in larger numbers.

Rita at the 'gate' (Photo: G. Hopwood)

Brewood Garden Party 2019: Visitors start to arrive.

After a few words from Phil Moon, the Vicar of Brewood, the Staffordshire Corps of Drums opened the proceedings with an impressive display of precision drumming, looking splendid in black trousers, red tunics and helmets.

Brewood Garden Party 2019: Staffordshire Corps of Drums perform the Official Opening.

There were the usual attractions, such as Tombola, Plants and Produce, Catapult Range, Coconut Shy and Toys and Books plus some innovations and variations such as 'Games and Names', 'Tuck Shop' and 'Crack the Code'.

The Refreshment Tent quickly became busy and remained busy. Both the local Midland Counties Co-op store and Brewood Post Office provided additional volunteers to provide welcome assistance to Beccy and the Scouts. This year, the local Spar store made a donation towards the cost of purchases for the Refreshment Tent.

Brewood Garden Party 2019: The Refreshment Tent.

Adjacent to the Refreshment Tent, Pimm's was available. The locally-brewed Slaters Ales 'One Hop' also proved popular.

Brewood Garden Party 2019: In addition to Pimm's, locally-brewed Slaters Ales 'One Hop' proved popular.

The Barbecue Tent completed the food and drink line-up. The picture shows a quiet moment as the Garden Party opened - from then on, there was no respite throughout the afternoon.

Brewood Garden Party 2019: Barbecue ready for business as the Garden Party opened.

We were delighted that Chase Ferret Rescue were able to join us again. The knowledge and care displayed by their volunteers was impressive.

Brewood Garden Party 2019: Chase Ferret Rescue ready to welcome visitors.

I find ferrets irresistible but not everybody relishes handling them so there was the option of walking ferrets on a lead!

Brewood Garden Party 2019: A 'paddock' adjacent to Ferret Rescue allowed children to walk ferrets on a lead.

Brewood Fire Station has 'Retained' Firefighters and they displayed their 'Big Red Fire Engine' in the drive. I was amazed at just how much specialist equipment was stowed in the many lockers and impressed by the capabilities of the computer display in the front cab which, for instance, can display a large scale map of the vehicle's current location showing adjacent Fire Hydrants. This attracted a lot of interest and we are grateful to the Fire Crew for their attendance.

Brewood Garden Party 2019: Staffordshire Fire and Rescue displayed Brewood's 'big red fire engine'.

There was also a 2-foot gauge steam locomotive as a static exhibit with Ann on hand to answer questions and this proved popular.

Brewood Garden Party 2019: Ann supervised a 2-foot gauge steam locomotive on static display which was popular with young (and not-so-young) people.

Brewood Garden Party 2019: Ann supervised a 2-foot gauge steam locomotive on static display which was popular with young (and not-so-young) people.

Everyone was delighted that, once again, the two bands based at the Cannock Performing Arts Centre - Cannock Big Band and Cannock Wind Band - returned to play for us.

Brewood Garden Party 2019: Cannock 'Big Band' gave another stunning performance.

Brewood Garden Party 2019: Cannock 'Wind Band' once again entertained with a 30-minute 'set'.

During the afternoon, the Staffordshire Corps of Drums gave a second display, for the benefit of later arrivals who had missed the opening ceremony.

Brewood Garden Party 2019: Staffordshire Corp of Drums gave an additional performance.

Brewood Garden Party 2019: General view.

The weather remained warm but the sun was not strong, making it more pleasant to walk around or just sit and enjoy the special atmosphere Brewood Hall seems to engender. All the comments I've received have been appreciative. Grateful thanks go to all those, from the village and elsewhere, who contributed to the success of the event by giving their time, or donating prizes or items for sale.

The organising committee have distributed the proceeds to the usual supported local charities: Brewood Parish Church, 2nd Brewood Scouts and the Jan Ford Foundation, with small donations to performing organisations.

Reports on other websites

Brewood 2nd Scouts have a report here.

Reports on previous garden parties at Brewood Hall

Brewood Vintage Garden Party 2013.

Brewood Vintage Garden Party 2014.

Brewood Garden Party 2015.

Brewood Garden Party 2016.

Brewood Garden Party 2017.

Brewood Garden Party 2018.

Pictures of the event

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures above may be selected, viewed or downloaded, in various sizes, from the album below:-

Brewood Garden Party 2019.