Shackerstone Station: Saturday, 30th June 2018

In 2018, 5542 returned to Shackerstone just after Easter following scheduled repairs at the South Devon Railway. My first driving 'turn' after the locomotive's return was a 'Fish and Chip Evening Special on Saturday, 9th June 2018 (described here) then I did a full day on Saturday, 23rd June 2018 when we had a 'Silver' Footplate Experience course prior to the service trains. A week later I was back again. You might imagine that driving the same locomotive on the same stretch of line a number of times would become boring. It never seems so to me - every trip is a little different.

Events of Saturday, 30th June 2018

In what struck me as a neat inversion of what had happened on the 9th June (when Carl was driver during the day and I took over for the evening service), this time I was driver for the five service trains during the day then, after watering the locomotive, I handed it over to Carl who was taking the evening round trip which, this time, was a Murder Mystery Dining train.

There was no Driving Experience Course prior to the first service at 11.00 a.m. so signing-on for Preparation duties did not have to be too early. But it's always helpful to have time on your side during preparation as the crew never know what may happen. Unusually, the married couple of Rod and Tracy Tye (both experienced footplate crew) were rostered as fireman on a 'buy one, get one free' basis so we were not under undue pressure.

On preserved lines, the driver and fireman sometimes have a safety-qualified trainee rostered as a 'Cleaner', both to learn about firing and boiler management and also assist in other tasks although this was not the case on the 30th. This practice is an echo of the old days when cleaners were given occasional trips on the footplate to learn the essential practical skills. Throughout their careers, footplatemen were helped to make progress in acquiring the necessary technical knowledge and familiarity with the Rule Book by attending Mutual Improvement Classes, briefly described here. A section of this blog (labelled 'MIC') has technical information of the sort which was formerly imparted in Mutual Improvement Classes. You can find all the posts labelled 'MIC' here or find a list of these posts (not always up-to-date) here.

Preparation

The term 'Preparation' covers both Driver's and Fireman's duties in getting a locomotive ready for traffic. In general, the Driver is responsible for the daily examination of the locomotive and 'oiling round' whilst the Fireman concentrates on raising steam but ideally the crew work together as a team to ensure that all the tasks are carried out efficiently. Proper attention to raising steam, oiling and the 'daily exam' helps to prevent failures 'on the road' later. There are a couple of posts in this blog dedicated to 'Preparation' activities on 'Austerity' tank engines:-

Driving Turn at Peak Rail - Part One: PreparationHowever, because of its importance, I tend to bang on regularly about Preparation in other posts as well.

Preparation of Locomotive 'Sapper'

Boiler Pressure

Great Western firemen were taught to keep the boiler pressure at the 'sizzling point', just below the red line (200 p.s.i. on 5542), as I mentioned in an earlier post:-

The Great Western were never seduced by the attractions of Ross Pop safety valves and always used their version of the early Ramsbottom design. This lets you bring the boiler pressure close to the blowing-off point with just a wisp of steam continuously escaping from the safety valves, in true Great Western fashion, rather than having the intermittent wasteful (and often noisy) discharge typical of Ross Pop safety valves. It was a point of honour amongst Great Western fireman to 'balance' the boiler with the valves just 'fizzing' to indicate to your driver (and everybody else) that you were on top of the job. Even when I was at Tyseley Railway Museum, if the pressure gauge was more than 10 pounds below the red line on a Great Western engine, the old-time enginemen would enquire "What's the matter? Won't she steam?".

(Battlefield Line Santa Specials 2011)

5542 Boiler and carriage warming pressure gauges.

Water Supply

On 5542, water is carried in two side tanks extending back into the cab, coupled by a broad Balance Pipe under the boiler. The '55XX' class had redesigned side tanks, giving a total capacity of 1300 gallons. The front of each tank carries a water filler and air vent. Usually, we take water at the column at Shackerstone (shown in the picture at the top of this post) after each round trip. Whilst running out of steam on a trip is embarrassing, at least the situation can be improved with time. But running out of water leaves the crew with no alternative but to 'throw out the fire' and totally disable the locomotive. Swindon provided their products with float-type water gauges and a tapered column rises above the fireman's side water tank in the cab indicating total water remaining in both Feet and Gallons.

5542 Water Gauge.

Although a full tank (1300 gallons) allows at least two round trips at Shackerstone, the possibility of the float gauge becoming stuck and giving a misleading reading or unexpected delays occuring, encourages crews to regularly take water.

Coal Supply

Coal is carried in a bunker behind the cab. The '55XX' class had a redesigned bunker with a 'bulge' or extension at the top to increase capacity.

Battlefield Line 'Santa' trains 9-Dec-2017: Last 'Classic' train of the day ready to leave Shackerstone. Note the bunker extension.

Great Western locomotive boilers were designed to use Welsh Dry Steam Coal, softer than anthracite with relatively low volatile content meaning the fuel was fairly slow to initially produce heat but, once going, sustained that heat longer as each individual lump swelled and opened up, giving the appearance of a cauliflower head. Competing railways initially believed that the use of 'Welsh' accounted for the superior performance of Great Western engines but the various Locomotive Exchanges, where Great Western locomotives continued to excel using 'bituminous' coals with a much higher volatile content (like the 'Yorkshire Hards'), showed that the real secret was the carefully-proportioned boiler design and the staff training.

Deep mines producing the traditional 'Welsh' have closed but a similar coal, using opencast mining, is currently in use at Shackerstone, I believe from Ffos-y-fran open cast coal mine in East Merthyr. It has many of the desirable features of traditional 'Welsh' but doesn't seem quite as good as the deep-mined Welsh I remember from my time at Birmingham Railway Museum. Any soft, Welsh coal is 'friable' and breaks up into dust readily. It's usually quoted as the reason the Great Western stayed with hand-coaling of locomotive tenders using men tipping skips of coal on a coal stage rather than investing in automated plant as widely used on other railways.

Events of Saturday, 21st July 2018: Diesel Substitution

2018 distinguished itself by providing a long, hot summer. With an absence of rain and farmers not yet having harvested, a number of preserved railways had to temporarily cancel steam operations because of the risk of setting fire to crops. The Battlefield Line was no exception and, on a number of dates, the Diesel Multiple Unit (DMU) replaced 5542. I'd been booked on 5542 for Saturday, 21st July, which was one of the cancelled steam days, so ended up with another DMU driving turn, which prompted the latest post here about DMUs. Following a period of cooler weather with rain, steam operations were able to resume.

Events of Saturday, 18th August 2018

I arrived at Shackerstone shed to find that Jamie, who was firing, already had matters well in hand and he was filling the Sight Feed Lubricator with steam oil.

Sight Feed Lubricator

Moving parts in contact with steam (such as the valves, pistons and regulator valve) require lubrication with a special, compound mineral oil, formulated to retain its properties at high temperature. Before mechanical lubricators became common, sight feed (or hydrostatic) lubricators were often used for this purpose and Swindon developed a range of excellent lubricators. Whereas many railways left the management of these lubricators to the fireman, the Great Western placed the Sight Feed Lubricator in front of the driver. Through training and the issue of circulars, Swindon ensured that drivers understood the method of operation and the importance of the Sight Feed Lubricator. A copy of Great Western Circular 5801 issued in November 1937 by C.B. Collett can be accessed (and downloaded) here.

5542 has the Triple Sight Feed Lubricator with 4 pint oil capacity. Steam from the boiler is condensed in two coiled tubes mounted in the roof of the cab (if one fails in traffic, it can be isolated and running can continue using the second coil).

Dual condenser coils for the Sight Feed Lubricator mounted in cab roof of 5542.

The lubricator itself is bolted on the boiler backhead, in front of the driver. The body of the lubricator is filled with steam oil and, when the main cock is opened, water from the condenser displaces oil through the main gallery and, when individual nipple valves are opened from the gallery, droplets of oil form inside the sight glasses, detach and are carried through oil lines to the front end. One of the two left hand glasses (as selected by a 3-position lever on top of the lubricator) serves the valves and cylinders, the one on the right (controlled by a distinctive knob) feeds the slide valve regulator in the smokebox. For more information, refer to the Great Western Circular linked above.

5542 Sight Feed Lubricator.

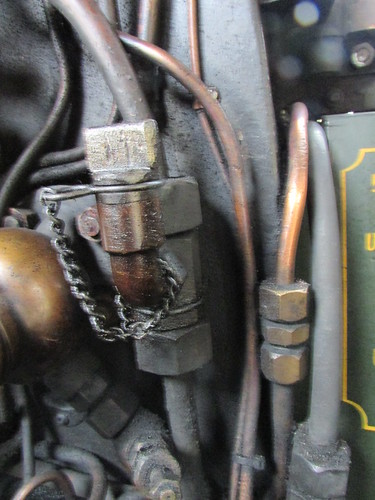

Jamie also added steam oil to the small oil cup on the feed pipe to the steam brake, to discourage the piston in the brake cylinder from sticking.

5542: Oil cup for feed pipe to steam brake.

In traffic

During the day, Jamie and I operated five round trips with a four coach train. The weather was hot, the footplate of 5524 hotter (even with the cab roof slid open). There were quite good passenger numbers and we both agreed we'd had a good day, although we were both dirty from the coal dust flying around and tired by the end of service

Related posts on this website

To see all my posts about the Battlefield Line, select Label 'Battlefield Line' or click here.

My photograph albums

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures may be selected, viewed or downloaded, in various sizes, from the albums listed:-

5542 GWR Locomotive

Battlefield Line, 2017-2018

All my Battlefield Line albums