Events of Saturday 9th December 2017

"Well, that didn't go quite as planned" I commented to Carl just after 9.00 p.m. as I left the railway after a long day. I'd arrived at 6.30 a.m. to drive the Great Western 'Light Prairie' 5542 and Carl had arrived earlier to drive 'Cumbria', the second engine in steam that day. We'd both experienced various difficulties during our shifts but managed to operate the booked service and, hopefully, had helped to make quite a few adults and children happy.

Preparation

I'd last been on 5542 on 22nd October 2017 when we'd had an enjoyable and trouble-free day (although the exhaust did sound a little 'off-beat'). There's a bit about Preparation in my post describing that day On the Footplate. I'm forever banging on about the importance of careful preparation of steam locomotives by both the fireman and driver and it's a recurring theme in my posts labelled 'MIC' in tribute to the Mutual Improvement Classes of the old steam railways which continue, in one form or another, for today's preservation volunteers.

5542 was at the north end of the locomotive shed, over the inspection and disposal pit, with 'Cumbria' 'brewing up' behind her and the resident engine 'Sir Gomer' hidden at the back, out of steam. Tracy was the fireman (we don't indulge in the politically-correct term 'fireperson') and, having done the initial checks, she'd just lit-up but was unhappy with the fire. Apparently, there was general agreement that the particular batch of coal we were working through was dusty, smokey and reluctant to make steam. However, she was confident she'd sort it so I carried on with oiling-round the locomotive. Harry was our cleaner.

The water tanks on a side tank design prevent access from the side under the boiler except at the very front so oiling all the inside motion and axleboxes on the leading and driving axles means 'going underneath' the engine and climbing up. I discuss the various methods of carrying water on tank engines and the resulting problems of access to inside motion in the post Water, water, everywhere.

Unless you're very fit and flexible, 'going underneath' requires the engine to be over an inspection pit. Ideally, the pit should not be as I found it, with various piles of ash remaining from previous disposals and two inches of water at one end which the electric pump had failed to clear. However, I eventually completed 'oiling underneath' and clambered out of the pit.

The smoke from two engines meant that visibility in the shed was very poor and small flakes of coal were falling like snow. Eventually, with aggressive use of the blower, our boiler 'came round' but it certainly wasn't steaming as I'd expect from a Great Western engine. Right at the beginning of the twentieth century, the designer Churchward introduced a range of very carefully-proportioned taper boilers with Belpaire fireboxes. They weren't cheap to build but they gave excellent water circulation producing very free-steaming locomotives.

5524 on the 'Classic' train

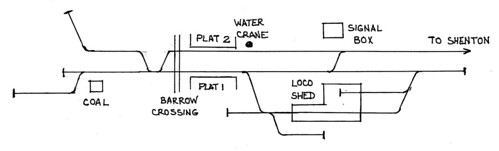

The rather cramped track layout at Shackerstone requires careful choreography to manage two trains. We were to take the first departure of the day - the 10.00 a.m. 'Classic' so the Ground Frame was operated to let us come 'off shed'. The 5-coach 'First Deluxe' train was standing in platform 1 and our 5-coach 'Classic' train was in platform 2. The stock in platform 1 had been positioned carefully, just leaving room for us to clear the points so that the Ground Frame could be restored. The signalman, Leon, then 'gave us the road' to move through the crossover onto the running line. With the crossover restored, he then 'cleared' the disc ground signal to allow us onto our train.

Shackerstone track diagram. North is to the left on this sketch.

Click on diagram for uncropped view.

Once we were 'out of the way', Carl was able to bring 'Cumbria' off-shed. But he had a special task before we started the service. Our self-propelled tamper, which had been 'working in the section' earlier in the week, had decided to expire near 'Airport Bridge' (on the Shackerstone side of Market Bosworth) so 'Cumbria' was despatched to drag the failure back to Shackerstone.

Battlefield Line 'Santa' trains 2017: Carl, driving 'Cumbria', arrives at Shackerstone having rescued the tamper.

Whilst 'Cumbria' was performing the rescue, we had coupled-up and started the steam supply for carriage warming. Our locomotive had a steam brake so, whilst light engine, it's conventional to leave the vacuum hose at one end of the locomotive 'off the stopper' so that the system operates as a 'straight steam' rather than a 'combination' (steam/vacuum) brake. Our Guard asked for vacuum but I noticed that our 'back bag' was still 'off the stopper' so I replaced this before placing the Driver's Combination Brake Application Valve in the 'create' position, so that the vacuum ejector would suck air from the train pipe and release the carriage brakes. Instead of the duplex brake gauge indicating the expected '25 inches' (partial vacuum is measured in 'inches of mercury'), it stubbornly stopped at just a few inches. Assuming that the fault was in the coaching stock, the Guard started to examine the coaches, noting a suggestion from Adrian that the exterior of the coaches had been washed during the week, so it was possible that a 'Butterfly Valve' had been disturbed. There's a brief description of 'Butterfly Valves' in the post MIC - The Working of Trains.

'Butterfly': The indicator for the communication cord on a passenger coach. With the 'flag' horizontal as shown the system is normal.

I didn't find out what our Guard discovered but, after a while, the vacuum came up to the required 25. The Guard should then do a 'Brake Continuity Test' by ensuring that taking the vacuum hose off the 'stopper' at the rear of the train destroyed the vacuum but, in practice, Guards often simply use the 'Setter' (the Guard's Brake Application Valve) in the Guard's compartment.

I'm afraid the Great Western, always prepared to be different, set their vacuum brake 'released' level at '25 inches' whereas every other British railway is content with '21 inches'. I think it was Churchward (before he succeeded William Dean as Chief Mechanical Engineer) working with Armstrong who made this decision. There's sound logic behind their thinking. 'Vacuum' brakes can be described as 'differential pressure' brakes. The bigger the differential between 'released' (a partial vacuum of 25 inches of mercury) and 'full application' (atmospheric pressure), the greater the brake force which can be produced by a brake cylinder of a given size. Looked at another way, more leakage can be tolerated in at system designed to run at '25 inches' before the braking effort available is seriously compromised. There's a little more on the topic in the post MIC - Brakes.

Ideally, the Guard or Driver would also carry out a functional brake test on the train. First, '25 inches' is created in the train pipe which should ensure that all train brakes are off. This vacuum is destroyed and the length of the train is inspected, ensuring that all brake blocks are 'on' (or, in practice, that all brake blocks on the non-platform side of the train are 'on'). If this is satisfactory, vacuum is re-created and the whole train is inspected again to ensure that all brake blocks are now 'off' and clear of the wheel tyres, with the exception of the Guard's coach, where the Guard's Handbrake will keep the brakes applied. The piston in each brake cylinder should be 'up' when the vacuum brake is applied and 'down' when the vacuum brake is released. Similarly, brake blocks should be tight against the wheel tyre when the brake is 'on' and hanging clear when the brake is 'off'. Where necessary, kicking a brake block will show whether it is 'on' or 'off'. I'm afraid I didn't carry out this test and I don't think the Guard did.

It's not unusual for Santa trains to be late away. All seats are normally pre-booked and, although the booking form clearly states "We are not able to hold departure of trains for late arrivals", the commercial department will often allow a few minutes 'grace'. When we finally received the 'Right Away' from the Guard, we made sure the handbrake was fully 'off' and I eased the regulator open. Steam poured from the open cylinder drain cocks but there was no movement. Vacuum was still correct, so I opened the regulator a little further. No movement. Sometimes, even with correct vacuum, some brake blocks on the train may be reluctant to drop clear of the wheel tyre. Rarely, the piston in the steam brake cylinder on the locomotive may 'stick' although, during preparation, cylinder oil is manually fed to the steam pipe leading to the brake cylinder from an oil pot in the cab to prevent this happening. Very rarely, the Guard may forget to release his handbrake (operated from a wheel in the Guard's Compartment). Finally, I opened the regulator even further and there was a small lurch from the engine. After a short pause, the whole train slowly moved. It was obvious that the exhaust beats from the chimney (four 'chuffs' for each revolution of the driving wheels) were uneven. With perfect steam distribution, they should all sound the same. No arrangement of Stephenson Link Motion gives perfect distribution, although Swindon's arrangement as used on the 'Light Prairie' comes close. But 5542 sounded distinctly unhappy.

As the train moved away, I 'linked up' the gear but left the cylinder drain cocks open a little longer because I'd seen that the boiler was rather over-full. The function of the cylinder drain cocks is to 'purge' the steam circuit and cylinders of condensed steam (water) which may collect whilst the engine is stationary. In a locomotive with slide valves, the 'buckle' which imparts the motion to the valve is arranged to allow the valve to move away from the port face which helps to clear any condensate. But the design of piston valves (as used on 5524) means that water can only escape through the drain cocks so 'aggressive' use of drain cocks becomes more important. Since water is incompressible, allowing a piston to squeeze water trapped in a cylinder risks serious damage, such as a broken cylinder cover or cylinder casting. Once I was happy that water had been expelled from the cylinders, I closed the drain cocks.

As we continued slowly up the cutting and passed under Barton Lane Bridge, things seemed a little better but I remained concerned at how 'off-beat' the exhaust sounded. We had been told to stop at Market Bosworth to pick up a staff volunteer. On receiving the 'Right Away' here, 5524 was once again rather reluctant to get under way but we carried on to Shenton and ran round our train. I discovered that the shunting signal controlled by the Guard from the ground frame reading from the run round loop to the single line had failed but the Guard displayed a green flag to authorise the movement. We coupled onto our train and created vacuum ready for the return journey, this time chimney leading. After a wait, the Guard whistled and displayed the green flag and we set off back to Shackerstone.

We arrived back late and were signalled into platform 2 at Shackerstone where I stopped with the leading coach just clear of the barrow crossing, meaning that our locomotive completely blocked the crossing. With the footbridge currently out of use, the barrow crossing is the only way for passengers to get to and from platform 1 so quite a crowd built up at the north end of the platforms waiting for us to uncouple and move forward into the North End sidings, where the bucket loading shovel was waiting to replenish our coal bunker.

Battlefield Line 'Santa' trains 2017: On our return to Shackerstone, we had to uncouple and draw away before passengers could use the barrow crossing.

With a full bunker, we moved back towards the station and stopped at the ground signal (lever 7: a Southern Railway pattern electrically-operated disc without the characteristic external floodlight). Ahead of us, our train was in platform 2 and the 'First Deluxe' train, with 'Cumbria' at the head, was still in platform 1. Once 'Cumbria had departed with the late-running 11.30 train, the ground signal cleared and we cautiously moved over the barrow crossing, ran through platform 1 negotiated the crossover outside the signal box. With the crossover replaced normal, the signalman cleared the "bottom dolly", allowing us to move onto our train and take water. We'd used about half a tank of water since leaving the shed that morning with a full tank. There was then nothing for us to do, except keep our train warmed, until 'Cumbria' returned with the 'First Deluxe' train, so I took a few pictures.

Battlefield Line 'Santa' trains 9-Dec-2017: Late-running 12 noon 'Classic' train ready to leave Shackerstone.

Santa Claus won't be hurried when he's distributing gifts on a train, so we were not surprised that 'Cumbria' returned having lost more time. We were keen to get started but, when we received the Green Flag and I opened the regulator, there was a loud, continuous 'blow' through the chimney but no movement. Having re-checked everything, I tried again, applying more power. The third attempt finally produced a sluggish movement and we slowly left the station, with a very uneven exhaust beat. We kept going but I couldn't be sure of the problem - possibly a broken piston valve ring.

Once again, we'd been asked to stop at Market Bosworth, this time so that train staff could establish how much more time Santa needed for his present distribution. On being given the 'right away' even full pilot valve regulator opening failed to produce movement as it should. The most likely reason was either a dragging brake or a damaged piston valve (or both). I put the reverser into 'Full Forward Gear' (we were bunker leading), opened the regulator and was rewarded by a few inches of movement. With the lever returned to 'Full Back Gear', this time we had movement in the intended direction and I was able to carry on to Shenton where, once again, we ran round our train. This time, we'd used half a tankful of water in just a one-way journey and Tracy was having to fire quite heavily to keep on top of things. I discussed our problem by mobile phone with Shackerstone and it was agreed that Adrian would take a look before we attempted our third and final booked trip that day.

Tracy firing 5524.

Tracy firing 5524.

We returned to Shackerstone without incident but had managed to use most of our remaining water, suggesting that a fair amount of steam was going to waste. Shortly after our arrival, 'Cumbria' left with with the second 'First Deluxe' trip that day. With platform 1 now clear, we were able to shunt to the other end of our train and re-fill the water tanks. We were then asked to propel our 5-coach train to the North End No 2 siding where it would remain until the next morning. The line from the platforms to the North Sidings is on a down grade so, after a small push to start the train, it was a case of controlling the speed of the movement with the brake until our shunter, at the far end of the train, signalled us to stop.

When 'Cumbria' arrived back, Adrian appeared and, having made arrangements with the signalman and I'd collected the Single Line Staff, he took us on a test run part way down the line and back light engine. We agreed that, with 'Cumbria' still in steam, it might be prudent to dispose of 5524 and use 'Cumbria' on the last train, the 'Santa Evening Train Special'. Leon in the Signal Box loosed us onto platform 1, so that we could use the Ground Frame to reach the shed. Unfortunately, the train in platform 1 had stopped a little short and, even closed-up to the coaches, we were not clear of the Ground Frame points. 'Cumbria' was no longer attached to the stock so it fell to us to find a shunter, couple-up, create vacuum and, under the control of our shunter, ease the train forward sufficiently to clear the points. With the Guard's handbrake securing the coaches, we uncoupled and moved the engine to the shed. Having made sure that there was plenty of water in the boiler of 5524, Tracy, Harry and I made our way to the station. Carl had watered 'Cumbria' and coupled it to the stock in platform 1. Once I'd relieved him on 'Cumbria', Carl then finished disposal of 5524 for us.

'Cumbria' on the 'Santa Evening Train Special'

In the section 'Notes on driving Cumbria' in the 2016 post Sunday at Shackerstone there's some information about 'Cum

Battlefield Line: Christmas illuminations for the 'Santa' trains 2017.

Our last run was timed to start at 6.15 p.m. and, of course, it was dark (we were just 12 days before the Winter Solstice). The passengers managed to arrive on time and we were only a little late departing. Driving on a traditional British steam railway at night is quite different from driving on roads. There's no powerful headlight and sound cues become more important to the driver to identify his position. Increased light pollution today means that the sky is rarely completely black - nearer tall objects can appear as a dark silhouette against a dark purple horizon, provided that the driver can retain his night vision when, each time the fireman opens the firedoors to feed coal to the fire, there's an intense white or yellow glare from the firehole. There's a little about driving at night on the Battlefield Line in the section titled 'The Specials' in the post 'Operation: Market Bosworth' - On the Footplate. There's a little more in general about railways at night in the post here.

Because Santa was making his way through the train greeting all our visitors, our speed was modest and we were asked to stop at Market Bosworth (where there were more Christmas illuminations on the platform). We were soon on our way again to Shenton, where the series of traditional lamp standards along the platform cast a dim but welcome glow. I eased-up the locomotive to make uncoupling easier but failed to persuade the regulator to close properly. After we were 'un-hooked', I couldn't get the reverser into 'full back gear'- it remained 'steam locked' in mid-gear. This is an irritating habit 'Cumbria' (and other engines) sometimes display which I discussed in the section 'Steam Lock' of the 2017 post Bank Holiday with Steam and Diesel. A bit of brute force (and a lot of not-very-ladylike language) eventually released the lever and we ran round without further delay. We were told to return gently as Santa completed his task but without stopping at Market Bosworth. On the Shackerstone side of Market Bosworth, we received the 'tip' that we could resume normal line speed so, complying with the lower limits through Headley's Crossing and the approach to Shackerstone, we were able to finish up with a little 'romp'.

I was careful to stop correctly in platform 1 at Shackerstone to leave room for 5542 to come 'off-shed' the following morning and we uncoupled. Then we were asked to re-position the 'Classic' train from the North Sidings to platform 2, ready for the morning. I was told we'd a shunter and I asked if the "strings had been pulled". 5542 had put the set in the sidings "blowing 25 inches". Since 'Cumbria' "blows 21 inches" it was essential that all the release cords along the train were pulled before I attempted to Create vacuum. On receipt of the 'move away' hand signal, I attempted to move but 'Cumbria' was slipping badly. Well, the train was on a reverse curve, on a wet rail with an adverse gradient and we were making slow progress so, encouraged by voices from the ground, I persevered for a while but when we stopped again I asked for "better and further particulars" of the string-pulling. It appeared that, in the dark, there had been some confusion and either not all the strings had been 'pulled' or the residual vacuum had not been fully discharged. After more delay, we received the 'move away' hand signal again and, this time, we slowly dragged the 5-coach train into position in platform 2. We then lost no time in uncoupling and moving to shed where we levelled the fire and filled the boiler. I completed the paperwork, made the "Well, that didn't go quite as planned" comment to Carl and went home.

Related posts on this website

Shackerstone Santa Specials.

All my Battlefield Line posts.

On the Footplate.

All my MIC posts.

My photograph albums

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures may be selected, viewed or downloaded, in various sizes, from the albums listed:-

5542.

Battlefield Line 'Santa' trains 2017.

All my Battlefield Line pictures.