A little history

The Shackerstone Railway Society was set up in 1969 and early passenger operations took place on a single-line between Shackerstone and Market Bosworth, using the original signal box at Market Bosworth to control a run-round loop at Market Bosworth. In 1992, the single-line was extended to Shenton (the re-opening is mentioned in my post here). The signal box at Market Bosworth was taken out of use and all the semaphore running signals were placed at 'clear' with a view to re-commissioning the signal box at a later date. The Single Line Train Staff which allowed one train onto the Shackerstone-Shenton single line was arranged as a 'Split-Staff' with two halves screwed together to facilitate re-opening Market Bosworth as a Block Post later with two single line sections (Shackerstone-Market Bosworth and Market Bosworth-Shenton) but, until the 2018 Gala, drivers have always had to have both halves of the Train Staff in their possession before setting off.

The complete Shackerstone-Shenton Single Line Staff, showing the 'Castell Key' used to release the Starting Signal (nowadays termed 'Section Signal') at Shackerstone.

In 1998, when the 125th Anniversary Celebrations of the Ashby and Nuneaton Joint Railway were held, Shenton Station Working was introduced where an engine was allowed to lay-by in the loop at Shenton ready to take the next arriving train back to Shackerstone, under the control of a Person in Charge at Shenton but I don't think that arrangement has been used for some time.

Train Staff Working

On a double-track railway where each line is used in one direction only (in the UK 'left-hand running' is usual) the biggest risk is a train running into the rear of an unexpectedly-halted previous train. The 'space interval' or Absolute Block system was introduced to address this danger.

But single-line railways needed a different approach from the start as there was not only the danger of one train catching up with another but the possibility of trains travelling in opposite directions meeting head-on. The evocative American phrase for this situation is 'cornfield meet'. In the U.K. the system of a 'Train Staff' was adopted. This was often a rounded length of wood (hence the name 'staff'). There was only one Train Staff for each single line section, marked with the section of line to which it applied. Before entering a single line, the driver took possession of the unique Train Staff and was thus assured that no other train was occupying the section. On clearing the single line, the driver would surrender the staff to the signalman or person in charge, allowing another train to enter the single line. Provided drivers were in possession of the Train Staff when on the Single Line, this simple system was safe.

To increase the capacity of the line, a long single line could be divided into separate sections by intermediate stations often provided with passing loops. There was only one Train Staff for each single line section, marked with the names of the two stations between which it applied. Again, provided the footplate crew made certain they were carrying the correct staff for the section, the system remained safe. Train Staffs could be distinctively painted or shaped to assist the driver and fireman in identifying the correct staff but enginemen were also expected to read the names of the stations marked on the staff as a cross check. When I was a trainee fireman in preservation, I was taught to collect the Train Staff from the Signalman (or person in charge), check the details, shout "Correct Staff!" then display it to my Driver so that he could independently satisfy himself that we had proper authority to enter the single line section.

This simple system was safe but inflexible. If trains alternated in direction on the single line, the first train carried the staff from station A to station B, the second train, in the opposite direction, returned it from station B to station A. But there was no way for a second train from A to B to follow the first whilst the Staff remained at station B. There are many tales of junior porters having to carry the Staff to the opposite end of the single line by bicycle.

Train Staff and Ticket Working

Train Staff and Ticket Working seeks to address the inflexibility of ordinary Train Staff Working. The signalman or Person in Charge at station A must be in possession of the Train Staff before allowing a train into the single line section.

If a second train will run in the opposite direction, the Train Staff is actually CARRIED by the driver of the first train so as to be available for the second train on arrival at station B.

If a second train will follow the first in the same direction, the driver of the first train must be SHOWN the Staff. Seeing the Staff gives assurance that another train has not entered the opposite end of the section. The signalman also issues a numbered paper Ticket to the driver, identifying the specific train and giving authority to pass through the single line. When the train arrives at station B, the ticket is surrendered to the Signalman or Person in Charge there who cancels the Ticket. Because the Train Staff is still at station A, a second train may follow, this time with the driver CARRYING the Staff (unless a further Ticket is issued because of a third train in the same direction).

With Staff and Ticket working, telephone communication between the Signalmen or Persons in Charge at either end of the single line is essential because a further Ticket must not be issued until any previous Ticket had been correctly received and cancelled. Before allowing a train onto the single line, the Signalmen or Persons in Charge at both ends must agree upon the direction of the NEXT train required to pass over the single line. Whether a driver receives the Staff or is shown the Staff and receives a Ticket depends upon the direction of the NEXT train through the section. If the next working is in the opposite direction, the Staff is carried to the other end so it can be given or shown to that train. If the next working is in the same direction, the driver is shown the Staff (so that it can be shown to or carried by the following train) and CARRIES the Ticket. Tickets are valid for one specific train and, after a single use, are cancelled by the Signalman or Person in Charge receiving the used ticket.

Introduction of Train Staff and Ticket Working for the 2018 Gala

By dividing the Battlefield Line into two Single Line Block Sections (Shackerstone-Market Bosworth and Market Bosworth-Shenton), it's possible to have a more intensive service, although trains in opposite direction cannot yet pass at Market Bosworth. Following modern British signalling practice, 'Distant' boards have been erected approaching Market Bosworth in both directions, followed by 'Stop' boards nearer the station. Trains are 'called by' the 'Stop' boards by a yellow flag displayed from the platform by the Person in Charge. Leaving Market Bosworth in both directions, further 'Stop' boards are provided, reminding drivers that they require the appropriate Train Staff or Ticket and permission from the Person in Charge before proceeding. All these arrangements had been designed by John W. who was also Person in Charge at Market Bosworth on both days of the Gala and had established a 'Train Control Office' at one end of the museum building on Market Bosworth platform which he had equipped with a Train Control Board giving a graphical display of trains as a reminder. Actual timings of all movements were recorded, just as the Signalman at Shackerstone recorded all movements in his Train Register Book. There's an introduction to the Train Register Book here.

A new passing loop at Market Bosworth is currently under construction which, when completed, will allow trains to pass one another.

Market Bosworth View from foot crossing looking towards Shackerstone showing the station and work in progress on the new passing loop.

In addition, the 'platform siding' through the station is to be controlled by Annett's Key from a 2-lever ground frame being installed at the north end of the station and this would also enable a train to 'lay-by' and be passed by another train.

Market Bosworth, October 2018: The 2-lever Ground Frame which, on completion, will control access to the platform siding.

With neither the loop nor the siding available for the Gala, operations were more limited but the use of Train Staff and Ticket working allowed the main train to leave Shackerstone for Shenton and, once it had cleared Market Bosworth, for another train (usually the 'Auto train') to leave Shackerstone and follow as far as Market Bosworth. The 'Auto train' could then return to Shackerstone and, once the 'Auto train' was clear of Market Bosworth, the main train could return from Shenton as far as Market Bosworth. Once the 'Auto train' had arrived back at Shackerstone, the main train could complete its run back to Shackerstone.

Whether a driver receives the Staff or is shown the Staff and receives a Ticket depends upon the direction of the NEXT train through the section. If the next working is in the opposite direction, the Staff is carried to the other end so it can be given or shown to that train. If the next working is in the same direction, the driver is shown the Staff (so that it can be shown to or carried by the following train) and CARRIES the Ticket. Tickets are valid for one specific train and, after a single use, are cancelled by the Signalman or Person in Charge receiving the ticket. Close co-operation between the Signalman at Shackerstone and the Person in Charge at Market Bosworth is clearly essential.

Events of 13th October 2018

I was rostered to drive 813 with Jamie W. initially firing until he was relieved by Rod T. later in the morning. Locomotive 813 had previously visited the railway back in 2007 and I'd been impressed then with what a lively, willing engine she was. There's a brief report on that visit here.

Locomotive 813 outside Shackerstone shed in 2007.

Our first working of the day was the demonstration freight train to Shenton, due to depart Shackerstone at 08:00. Jamie and I were delighted that Adrian L. had agreed to light-up and start oiling round, making a much easier start for us both. In the days of steam on the 'Big Railways', 'P and D' ('Prep and Dispose') turns were commonplace where a driver and fireman would spend the whole shift in and around the locomotive shed either preparing engines to go out (steam-raising and oiling-round) or 'putting to bed' incoming engines (coaling, watering and either cleaning the fire or withdrawing it, depending upon the engine's next duty). In preservation, having Preparation or Disposal done for you is unusual.

I had intended to complete the oiling-round myself but the new system of working, with the line divided into two single line sections (Shackerstone-Market Bosworth and Market Bosworth-Shenton) was being introduced that day and by the time I'd attended the induction meeting held by John W. for all the loco. crews and signed to confirm that I understood the arrangements for Train Staff and Ticket Working, Adrian had completed the oiling.

In the post Santa Specials at the Battlefield Line 2017 I commented "The rather cramped track layout at Shackerstone requires careful choreography to manage two trains". For the Gala, we had three locomotives and three trains - 4-coach passenger, 1-coach passenger ('Auto train') and Freight train so the moves had to be well-planned by the Director of Operations.

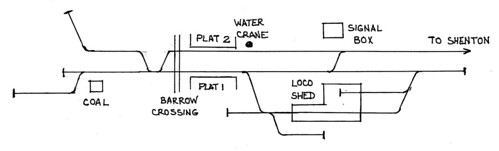

Shackerstone track diagram. North is to the left on this sketch.

Click on diagram for uncropped view.

The loco shed at Shackerstone is a 'straight shed' and, from the main door, the locos had been stabled in the order 6412, 813 and 5542. So we had to wait for 6412 to move forward into platform 1 and set back into the DMU Siding adjacent to the shed where the Great Western 'Auto' coach was stabled before we could come 'off shed' and couple onto our freight train waiting in platform 1. The train make-up was:-

Box VanThe Hand crane and Brake Van are recent arrivals from the now-closed Electric Railway Museum in Coventry.

Long wheelbase tool van

LMS Hand crane

Match wagon

LNER Brake van

With Carl M. as Guard on the brake van, we set off. We were due to be back at Shackerstone before the first passenger working so, as expected, we were issued with the 'half-staff' authorising movement to the 'Stop' board approaching Market Bosworth.

Working loose-coupled freight trains requires some care since there is always slack in the couplings and, apart from the Guard's screw handbrake, only the locomotive has a working brake but with such a light train I didn't anticipate problems and there were none. Although the morning was still rather damp, we passed a number of photographers before slowing for the new 'Stop' board approaching Market Bosworth. Spotting a yellow flag displayed from the station platform, I gave a 'pip' on the whistle in thanks and kept the train rolling into the platform. I surrendered the Shackerstone-Market Bosworth 'half-staff' to John W. and was issued with the other 'half-staff' authorising movement between Market Bosworth and Shenton. This half of the staff includes an Annett's Key which would allow us the unlock the Ground Frame at Shenton. John W. also gave permission for us to pass the 'Stop' board so we continued our pleasant run to Shenton.

I'm afraid we don't often have the chance to run demonstration freight trains at the Battlefield Line. I think my last freight at Shackerstone was during the 2015 Gala, described here. On that occasion, the freight was 'double-braked', with a brake van on each end, so running round at Shenton was similar to running round a passenger train. But in 2018, we only had one brake van so we had to move it to the other end of the train before returned to Shackerstone. My earlier report on the 2015 Gala mentioned a favourite question posed to trainee shunters:-

Simple loop at end of a branch: one engine, set of wagons, one brake van arrives. What are the moves to run round and go back?So, on arrival at Shenton, that's what we did. After detaching the brake van, we drew the wagons just clear of the loop points leaving most of the train outside the platform. This was the first proper run these wagons had been on in some time so, although they'd all been previously got ready for their excursion, Carl and I agreed it was prudent to examine both sides of the train and check for any overheating in the axleboxes before returning. Everything was (literally) 'cool', so we completed the moves, using the 'half-staff' to release the ground frame controlling the loop points. Carl obtained permission from Market Bosworth Train Control to return and, with the 'half-staff' back on the engine, we set off bunker-first.

The arriving train stops with the brake van just outside the loop points. Van brake is applied and brake van is uncoupled. Engine draws wagons into line 1 and sufficient wagon handbrakes are applied before engine uncouples, draws forward to headshunt, reverses round line 2 to the brake van, attaches it and takes it forward round line 2 to the headshunt, then propels the brake van onto the waiting wagons. Brake van is attached to wagons, brakes set as required, engine uncouples, forward into headshunt, reverse around line 2 until outside the loop points which are then set towards the wagons. Finally, engine moves forward onto the wagons and couples. Job done!

Shenton Ground frame. The 4-lever frame is released by inserting the Train Staff into the lock near the bottom of the rightmost lever.

Approaching the new 'Stop' board at Market Bosworth, I whistled to announce our arrival and received a yellow flag from the platform, which I acknowledged with a 'pip'. In the platform, John W. received the Market Bosworth-Shenton staff, issued the Shackerstone-Market Bosworth staff and gave permission to pass the new 'Stop' board leaving Market Bosworth. We set off for a gentle romp home, again passing a few photographers.

At Shackerstone, the tall lattice post home signal (No. 2) came 'off', the lower disc ground signal outside the box (No. 3) came 'off' as we approached, we surrendered the Train Staff to the signalman waiting on the landing outside the box and brought our train to a gentle stop short of the 4-coach main train standing in platform 2. When a main running signal (like No. 2) is off, the driver is assured that the line is clear at least up to the next signal, but a ground signal 'off' only authorises movements "as far as the line is clear" towards the next signal. We'd had a great trip but, following a late start, we were still about 15 minutes late arriving.

Shackerstone Signal Box, showing the 2-disc ground signal controlling movements into platform 1 (top disc) or platform 2 (bottom disc).

The next move was the first single-coach 'Auto Train' to Market Bosworth, with 'Pannier' 6412 propelling the coach with the driver, Adrian A., controlling the train from the driving compartment in the 'Auto trailer'. Numerous people watched expectantly as the 'Auto' eventually left at 09:20, 20 minutes 'down'.

Battlefield Line Steam Gala 2018: 813 simmers after the freight train run and the 'peg' is off for the first 'Auto Train' of the day. 5542 waits to come off shed.

Battlefield Line Steam Gala 2018: The first 'Auto Train' leaves Shackerstone.

Once the 'Auto Train' had left, there was a period of furious activity as the freight train was stabled in the DMU Siding alongside the shed, out of the way, and 5542 moved onto the coaches in platform 2 before the 'Auto Train' returned.

Battlefield Line Steam Gala 2018: The first 'Auto Train' arriving back at Shackerstone.

After 5542 had left with the late-running 09:30 to Shenton, Shackerstone became quiet again. The timetable called for 5542 to complete its round trip, after which the 'Auto Train' was scheduled to make its second trip to Market Bosworth at 10:30. At that point, we were still about 20 minutes adrift.

Battlefield Line Steam Gala 2018: The second 'Auto train' leaves Shackerstone, viewed from 813 standing on the DMU siding.

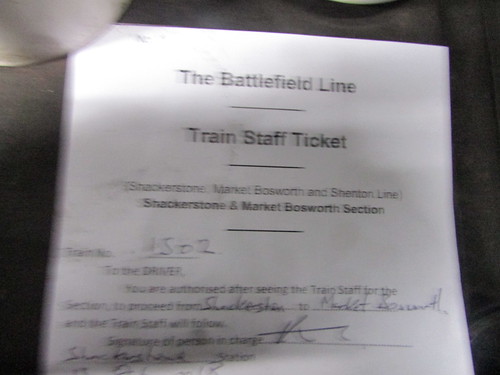

With the 'Auto train' away, I was able to shunt 813 across to platform 2 and attach to the 4-coach train for our first passenger working. Once the 'Auto' was back, we were able to leave. It should have been 11:00, but we were still about 17 minutes late. This time, the 'Auto' was to follow us after we'd reached Market Bosworth, so I was shown the Train Staff and issued with Train Staff Ticket No. 1, issued to train 1S02 (the second Shenton train). I placed the ticket on the shelf at the back of the cab, with two empty pottery mugs as paperweights.

Battlefield Line Steam Gala 2018: Leaving Shackerstone with 813 on the late-running 11:00 train.

All went well until we were past the photographers near Headley's Crossing when a sudden, strong cross-wind whipped everything off the shelf at the back of the cab. A plastic cup of tea I was about to sample emptied itself in Jamie's direction and, when I checked, Train Staff Ticket No. 1 had disappeared. We continued to Bosworth and I sheepishly admitted my failure to John W., offering a fuzzy photograph of the missing item as a substitute. I resolved to thereafter carry Tickets in a pocket, for safety.

Battlefield Line Steam Gala 2018: Train Staff Ticket No. 1

We were issued to the Market Bosworth-Shenton train staff, were given permission to proceed and completed our run to Shenton without further incident. We ran round our four coaches, ready for the return run. All went to plan to Market Bosworth. In the platform, I surrendered the Market Bosworth-Shenton staff and John W. issued the Shackerstone-Market Bosworth staff, also giving us permission to pass the new 'Stop' board leaving Market Bosworth. Once all the passengers had sorted themselves out, we received the 'Right Away' from the Guard and set off up the bank.

On a standard Great Western engine, the vacuum ejector would normally be used only until the speed had reached 15 m.p.h. since the vacuum pump could then be relied upon to maintain the required 25 in/Hg (inches of mercury) partial vacuum in the train pipe until the next brake application was made. But 813, being a 'Swindonised' Hudswell Clarke, lacks a vacuum pump so the vacuum ejector must be used as required.

The Great Western combination steam/vacuum brake application valve fitted to 813 (shown in 'Fully Applied' position).

It became clear that 813 had gone 'off the boil'. Performance deteriorated as the boiler pressure fell and then the ejector had difficuly maintaining the vacuum. Speed dropped further as the train brakes started to drag, despite Jamie's attention to the fire. Shortly after Headley's Crossing, it was obvious we'd have to 'stop for a blow up' so we came to a gentle stop and applied the handbrake. Carl M. descended to the track and we agreed to 'pull the strings' on the train, which would allow to us to complete the journey to Shackerstone with a slightly lower partial vacuum above the brake pistons, if the boiler remained reluctant to steam. Carl and I made sure all eight brake pistons on the train were fully 'down', releasing the coach brakes, by which time matters on the footplate looked far healthier. Having lost a few more minutes, we were then able to finish the journey back to Shackerstone.

5542, attached to the freight, was waiting for us to arrive so that the delayed noon freight train could set off. Once the freight had passed Market Bosworth, 6412 followed with the fourth 'Auto train' of the day to our middle station and back. Meanwhile, 813 was run round, watered and made ready to work the third passenger service of the day to Shenton. By this time, Rod had relieved Jamie as fireman and I explained the problems we'd had with the brakes on the previous trip.

I'm not sure how late we were departing by the time 5542 returned with the freight but, once we were clear of the restrictions up to Barton Road Bridge, I gave 813 full First Valve, well linked-up, and she ran like the proverbial sewing machine. There's a very short restriction to 10 m.p.h. near the Water Works but, once past this, we ran down the bank past Airport Bridge in fine style. I braked, prepared to stop at the new 'Stop' board but John W. gave us a yellow flag so I was able to keep the train moving into the platform at Market Bosworth. I extracted the folded-up Ticket from my overall pocket and delivered it to John who gave me permission to proceed and the Market Bosworth-Shenton Train Staff. Having observed the speed restriction leaving the station and across the underbridge near Deer Park Siding, I was able to open-out 813 a little and we made an excellent run, finally slowing for the 5 m.p.h. 'slack' near the Ambion Lane underbridge and the approach to Shenton Station. The weather was now dry, the sun had appeared and there were lots of visitors admiring 813 as we ran-round the train. Rod kept the boiler 'up to the mark' so we enjoyed an excellent run back to Shackerstone.

5542 had disposed of the freight train and was ready to 'hook-on' to the south end of the main train to work the delayed two o'clock departure to Shenton. As usual, once 5542 had left Market Bosworth, the 'Auto train' made another trip to 'Bosworth and Back'. But, this time, when 5542 returned from Shenton with the 4-coach main set, rather than the 4-coach train forming the next train to Shenton (the late-running three o'clock), this time the 'Auto train' was to go all the way to Shenton. With 5542 on the south end of the 4-coach train and 813 on the north end, the idea was that the 'top-and-tailed' main set would follow to Market Bosworth and back for variety.

The sight feed lubricator on 813 chose that inopportune moment to "throw a wobbly" (having worked perfectly until then). It shouldn't have been empty, but we drained the lubricator, refilled it with the specified 680 SAE compound steam oil and attempted to restart it. I failed: Rod, Adrian and Carl failed so the Director of Operations decided to cancel the 'top and tail' working. Unfortunately, by this time, the 'Auto train' had already left, carrying a Ticket, in expectation of the 'top and tail' working following to Market Bosworth with the Train Staff. So, (shades of the junior porter story mentioned earlier), a Volunteer who was just about to leave for the day was asked if "he wouldn't mind just dropping off the Train Staff at Market Bosworth on the way". By this method, the 'Auto train' was finally able to return to Shackerstone but the four o'clock service to Shenton, hauled by 5542 was now quite late, so the five o'clock service, which should have been 813's last train was cancelled. 813 was coaled, watered and assisted with the re-marshalling of the freight train ready for the following morning. I then handed over the locomotive and booked off since I would be back again the following day (on 5542). 813 would be the last locomotive into the shed on Saturday evening because it was the first engine required the next day.

Not all the arrangements for the ambitious timetable had worked but I'd had an enjoyable day, as I hope did the other Volunteers and our visitors.

Lubricating the steam circuit in locomotives

Moving parts in contact with steam (such as the valves, pistons and regulator valve) require lubrication. 813 is provided with oil cups on the front of the cylinders, accessed by opening the hinged 'piano front' under the smokebox door.

813 stands in front of Shackerstone resident 'Sir Gomer' in 2007. 813's hinged 'piano-front' can be seen under the smokebox door, with a single, central knob.

On early locomotives, one 'dose' of oil to this type of cylinder oil cup during preparation, possibly repeated later, would frequently be the only oil supplied to the steam circuit. With lower boiler pressures and saturated steam, the entrained moisture in the steam could be quite an effective lubricant. The introduction of higher-temperature steam, especially when 'Superheating' was used, required better compound steam oils which could retain their properties at higher temperatures and a more consistent method of feeding the oil. For a long time, the Sight Feed Lubricator provided the required reliability of oil feed until the use of mechanical lubricators became widespread. Even non-superheated locomotives (like 813) could benefit from the installation of a Sight Feed Lubricator and 813 has one, mounted in front of the driver. Although private locomotive builders started to fit sight feeds where specified, I suspect the one on 813 is a Swindon modification as it appears to employ some parts used elsewhere by Swindon.

GWR loco 813, October 2018 The Sight Feed Lubricator.

Related posts on this website

Battlefield Line Steam Gala 2018 (Part 2)

The last Steam Gala at the Battlefield Line was in 2015 and my report on that event is here.

Locomotive 813 previously visited the railway back in 2007 and my report on that visit is here.

To see all my posts about the Battlefield Line, select Label 'Battlefield Line' or click here.

My photograph albums

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures may be selected, viewed or downloaded, in various sizes, from the albums listed:-

5542 GWR Locomotive

813 GWR

Battlefield Line Steam Gala 2018

Battlefield Line, 2017-2018

All my Battlefield Line albums

[Link to part 2 added 4-Jan-2019]