skip to main |

skip to sidebar

Events of Sunday, 21st June 2015

Once again, I was the driver on 'Lord Phil' with Richard (now a 'Passed Fireman' and able to perform driving turns) as fireman. As usual, we were 'top and tailing' with the Class 31 and a load of six coaches. This was the day of the Preserved Bus Gathering so there were lots of preserved buses on site, making a very colourful scene.

View of Rowsley station car park as 'Lord Phil' sets off for Matlock Town.

View of Rowsley station car park as 'Lord Phil' sets off for Matlock Town.

The Bus Gathering is organised by the Chesterfield 123 Preservation Group and they reported 64 buses attending, of which 24 ran in service. When we passed through Darley Dale during the day, we normally spotted one of the 24 buses in passenger service, making an attractive juxtaposition of train, level crossing and bus.

A London 'Routemaster' parked at Darley Dale station, a long way from Marble Arch.

Preserved Chesterfield bus passes over the level crossing at Darley Dale.

Preserved Chesterfield bus passes over the level crossing at Darley Dale.

We usually make a special attempt to make our last arrival at Matlock Town on a Sunday 'right time', as passengers from our train are sometimes hoping to make a connection with the East Midlands Trains service to Nottingham. With the various permanent and temporary speed restrictions in force, this is not always an easy task.

2-car train of Class 156 units arriving at Matlock Town.

2-car train of Class 156 units arriving at Matlock Town.

The Class 31 hauled us back to Rowsley, Richard uncoupled and we took our engine across to the pit outside the engine shed and completed our disposal duties.

'Lord Phil' stands on the pit outside the engine shed.

'Lord Phil' stands on the pit outside the engine shed.

Related posts on other sites

Chesterfield 123 Preservation Group.

Related posts on this site

Vintage Commercial Vehicles at Peak Rail.

All my posts on Peak Rail can be found here.

My pictures

Peak Rail Preserved Bus Gathering 2015.

A steam engine needs a 'working fluid' to move heat from where it is generated (by the combustion of a suitable fuel) to where it is converted into mechanical energy. Water is boiled to make steam which readily flows to where it is converted into mechanical energy, usually in a reciprocating cylinder. Hence, a railway locomotive must carry water as well as fuel.

In England, steam locomotives were normally identified by counting wheels using Whyte's Notation. For instance '4-6-2' means four leading carrying wheels, six coupled wheels providing traction and two trailing carrying wheels. The English were never seduced by the equally reasonable idea of counting axles until the widespread adoption of diesel and electric traction, although Bullied called his 'Merchant Navy' Pacifics the '2 1 C' class.

If no qualifying letter was appended, it was assumed that there was a tender to carry the required water and fuel so, for instance, '0-6-0' implied a six-coupled locomotive with a tender.

It was convenient to produce designs omitting a tender for shunting or shorter distance working but this meant that the water tank had to be carried on the engine frames, together with the necessary fuel. The suffix 'T' is used to indicate 'Tank' and we call such engines 'Tank Engines'. In Germany, the term 'Tenderlok' is used for designs without a tender.

Early tank engines often carried water in a tank squeezed between the frames, underneath the boiler, rather limiting water capacity but early designers were very wary of raising the centre of gravity. I've driven an 1874 industrial six-coupled locomotive like this called 'Bellerophon' (not to be confused with the L.M.S, 'Jubilee' 4-6-0 of the 1930s). By providing outside cylinders and outside Gooch motion, a reasonable size water tank was included. A 'W' is often added to the designation to indicate 'Well Tank' so 'Bellerophon' is an 0-6-0WT.

Visiting locomotive 'Bellerophon' at Manchester Museum of Science and Industry, carrying smokebox wreath and explanatory notice on the bufferbeam, commemorating the death of Mick Todd who was closely associated with the restoration of the locomotive.

Beattie designed a 2-4-0WT. I've driven both survivors. He somehow crammed inside motion (Stephenson Link, if I remember correctly) in front of the water tank, severely restricting capacity, so the lower part of the coal bunker is an extra water tank. I've written a post about these delightful engines here.

30585, still in steam, is chained in position on the low loader.

30585, still in steam, is chained in position on the low loader.

The 'saddle tank' was widely used, the name suggested by the curved shape of the tank placed on top of the boiler barrel, used particularly in small four-coupled engines like 'Henry' described here. An 'S' is often added to the designation. Saddle tanks are also used on larger 6-coupled locomotives like 0-6-0ST 'Sapper', described here. At least there's some space between the foot-framing (running plate) and the bottom of the tank to perform oiling and inspection. The disadvantage is that the water tank construction is complicated by the need to allow the chimney, dome and safety valves to pierce the tank, unless the tank is shortened to avoid either the chimney or safety valves.

0-6-0ST 'Sapper'.

0-6-0ST 'Sapper'.

Carrying water in two flat tanks either side of the boiler then became a common practice. No extra letter was allocated so, for instance, 'Thomas the Tank' remains simply an 0-6-0T. I've driven a number of side tank locomotives (including a few posing as 'Thomas'). When you prepare a side tank with inside motion (which most British engines had), you quickly find the big disadvantage - access to the motion becomes very difficult, encouraging not-very-ladylike language.

47298, posing as 'Thomas' shows her classic Midland lines and an odd paint job.

47298, posing as 'Thomas' shows her classic Midland lines and an odd paint job.

My posts on various 'Thomas' locomotives, all side tanks, are here.

The Great Western Railway used side tanks on its larger tank engines - this arrangement probably allows the largest water capacity.

'Light Prairie' 5542 ready to depart from Shackerstone on the Battlefield Line.

'Light Prairie' 5542 ready to depart from Shackerstone on the Battlefield Line.

I'm afraid Britain was very slow to adopt a layout with two outside cylinders and outside Walschaerts motion, which eliminates the problem of access to the motion and allows full-length side tanks, although I've driven at least one such 0-4-0T - 'Cadbury No. 1' built by Avonside which worked at the Bournville chocolate factory.

'Cadbury No. 1' has outside cylinders and Walschaerts motion, allowing full-length side tanks. The engine is currently out of traffic.

For their smaller tank engines, the Great Western Railway came up with a tank layout which allowed improved access to inside Stephenson Link Motion. Their solution has much to commend it - they used two 'pannier' water tanks allowing access to inside motion but leaving the top of the boiler unencumbered. A letter 'P' is often added to the designation. I've driven six or seven different 'Pannier' 0-6-0PT but not written a lot about these engines. These are capable, versatile engines and, as my friend John likes to remind me (after I used the phrase on a railway video) "You can do anything with a Pannier". There are some pictures of one example (5786) here. There are pictures of a later version (9466) which, remarkably was not built until 1952, here. I think Belgium was one of the few other countries which used the 'pannier' principle.

Pannier tank 5786 'on shed' at Shackerstone.

Pannier tank 5786 'on shed' at Shackerstone.

Perversely, when the Great Western Railway did use Walschaerts motion (on the 4-cylinder express engines) they put it between the frames making access even worse than with link motion - just try oiling a 'Castle' or a 'King'. But valve motions are another story.

The Post Title

"Water, water, every where" is a line from The Rime of the Ancient Mariner by Samuel Taylor Coleridge.

On Sunday, 12th April 2015, Pathfinder Tours (2006) Ltd organised a Midlands rail tour, hauled by a pair of Class 20 from Direct Rail Services. Their advertising material said:-

No not a Trumpton tour but to locations in the Derwent Valley - an intriguing ramble around unusual lines in the Midlands, headed by English built locomotive types that are still giving sterling service over fifty years since built. With plenty of non-passenger line coverage we hope this Midlands perambulation will appeal to you. The on board catering will include both a buffet service, real ales and the Gricers Grill (with 'Roastie' option). MOTIVE POWER IS EXPECTED TO BE DRS CLASS 20 DIESEL LOCOMOTIVES WITH A DRS CLASS 37 ASSISTING IN THE MORNING BETWEEN DUDLEY RUN ROUND SIDING AND BROMSGROVE. Pick up stations: Crewe, Stafford & Walsall.

N.B. Trumpton’s fire brigade roll was :Pugh, Pugh, Barney McGrew, Cuthbert, Dibble and Grub.

Well, the Trumpton allusions were lost on me, but help was at hand in the Trumpton article on Wikipedia.

This railtour was ending up at Rowsley on Peak Rail and I was rostered as steam driver on the Peak Rail service. As usual, we were top-and-tailing with 'Lord Phil' on the south end of the train. The timetable was amended so that the Peak Rail train was waiting in the Up Platform at Darley Dale, allowing the 'special' to pass us using the Down platform on its way to Rowsley.

Peak Rail, 2015: The Pathfinder Railtour passing Darley Dale en route to Rowsley. Jack, the Peak Rail Conductor, surrenders the Matlock-Darley Dale token to the Darley Dale Signalman.

Peak Rail, 2015: The Pathfinder Railtour passing Darley Dale en route to Rowsley. Jack, the Peak Rail Conductor, surrenders the Matlock-Darley Dale token to the Darley Dale Signalman.

We then proceeded to Matlock Town, returned to Darley Dale and stood in the Down platform. Meanwhile, the pair of Class 20 had run round the train at Rowsley and returned to Darley Dale, stopping in the Up platform. The railtour had to wait for the 'road', giving us a chance to chat to the Direct Rail Services driver before we continued to Rowsley.

Peak Rail, 2015: The returning Pathfinder Railtour arriving at Darley Dale.

Direct Rail Services:

I hadn't realised until I wrote the post Furness and the Cumbrian Coast (Part 1) that Direct Rail Services was owned by the Nuclear Decommissioning Authority which is an Executive Non-Departmental Public Body (NDPB) reporting to the Department of Energy and Climate Change. Originally, it solely operated nuclear flask trains, but its work has now expanded and you can find out more here.

Other Railtours at Peak Rail

There have been a number of Railtours to Rowsley, some of which I've described in this blog:-

Steam Charter to Peak Rail.

The 'Peak Forester'.

HST Charter to Peak Rail.

My pictures of the Dimple, Darley and Dale

Peak Rail 2015 (part of album).

Brewood Garden Party took place at Brewood Hall on the 11th July 2015. This event was held at Brewood Hall for the first time in 2013 (there's a report here) and was repeated the following year (report here). The first two years had been blessed with hot, sunny weather and I'm pleased to report that the 2015 event enjoyed similar conditions.

Setting up

On the evening of the day before the Garden Party, a large number of Scouts and Scout leaders arrived to unload the various vehicles and trailers bringing the materiel needed, erect the various tents and sort the equipment ready for the final preparations on Saturday morning.

Unloading the first of many deliveries of equipment needed for the garden party.

Unloading the first of many deliveries of equipment needed for the garden party.

The volunteers worked quite late. As previously, two large modern frame tents were erected as the refreshment area and a similar tent was set up for games and stalls. The most demanding task was erecting the large canvas marquee which required good teamwork.

Erecting the large marquee.

Erecting the large marquee.

There was also a 'gazebo' tent and a futuristic-looking Coleman Event Shelter (I didn't know the Coleman brand but there's quite a nice video illustrating the history of the Company here. After watching the video, the 'Back Button' will return you to this post).

On Saturday morning, volunteers arrived to complete the setting-up, ready for the opening to the public at 1.00 p.m.

The Garden Party

By the time all was ready to admit visitors, a small queue had formed outside the entrance gates.

The entrance gates, viewed from the road.

The entrance gates, viewed from the road.

My friend Rita manned the Admission Table.

My friend Rita manned the Admission Table.

Marilyn Coulter from the parish church performed the official opening (before dashing back to St. Mary's and St. Chad's to perform a wedding, after which she returned to the garden party). A popular innovation this year was live music performed by two bands from the Cannock Performing Arts Centre:-

The 'Wind Band' at 1.15 p.m.

Cannock Performing Arts Centre 'Wind Band'.

Cannock Performing Arts Centre 'Wind Band'.

The 'Big Band' at 2.30 p.m.

Cannock Performing Arts Centre 'Big Band'.

Cannock Performing Arts Centre 'Big Band'.

There's also a short video of the 'Big Band' here. After watching the video, the 'Back Button' will return you to this post.

Both bands are supported by the Friends of Cannock Performing Arts Centre who manned a stand.

Friends of Cannock Performing Arts Centre - 'Supporting young musicians'.

Friends of Cannock Performing Arts Centre - 'Supporting young musicians'.

The P.D.S.A. and the Staffordshire Corps of Drums manned stands. 'The Trading Post' (which is Brewood Scouts own charity shop in Brewood) moved some of their stock to a stall at the garden party and the volunteers were kept busy. The large marquee hosted a number of craft stalls, a sweet shop and the judging for the cake-making contest. The refreshment tent was, as always, popular. The good weather encouraged many visitors to sit at the tables which had been provided outside the tent.

The refreshment tent.

The refreshment tent.

Various games were laid on. The wet sponge throwing at a human target was always busy, as was the Coconut Shy.

The Coconut Shy.

The Coconut Shy.

Another traditional entertainment for younger visitors was provided by a series of Sack Races and Egg and Spoon Races. These proved very popular.

Visitors were able to enjoy the location and the sun.

Visitors were able to enjoy the location and the sun.

Everybody seemed to enjoy their visit and useful funds were generated which, this year, were divided between Brewood Scouts and the Jan Ford Foundation (supporting educational and medical charitable work in Myanmar).

Related posts on this site

Brewood Vintage Garden Party 2013.

Brewood Vintage Garden Party 2014.

More information on the charitable work supported by the Jan Ford Foundation in Myanmar (formerly Burma) can be found:-

Education Support

Medical Support.

Pictures of the event

Brewood Garden Party 2015

On Easter Saturday 4th April 2015, I was booked out on '3803' with Dave as fireman. We both set-to to prepare the locomotive, Dave concentrating on steam-raising whilst I 'oiled round' and carried out the 'Daily Exam'. It can get rather smokey inside the shed so, as soon as we had sufficient steam to move the locomotive safely, I moved the engine outside.

3803 outside the shed at Shackerstone.

3803 outside the shed at Shackerstone.

3803 looked very business-like in her new unlined black livery (thanks to Jason's hard work) with the original British Railways insignia on the tender, which we used to call the 'Lion astride a Mangle-wheel'.

There were spare vehicles attached to the passenger stock in platform 2 and an '04' shunter. I'd worked out how we could shunt them out of the way with '3803' but Adrian arrived and carried out the shunt, allowing us to move across to our train in platform 2 in plenty of time for the first departure at 11:15. The locomotive carried a special headboard 'EASTER EGGS-PRESS'.

Leaving Market Bosworth on the first service, there was a bit of a 'thump'. Since the locomotive had suffered a run of broken springs, any loud noise from 'underneath' triggered an inspection of springs at the earliest opportunity but at Shenton Dave's examination found no problem and I thought the noise was probably from the intermediate buffers between engine and tender which were known to produce the occasional 'bang'. However, on the second trip as we left Market Bosworth, I caught a glimpse of an odd-looking 'lump of metal' in the cess and spent the rest of the journey to Shenton trying to decide what it might have been. I'd more or less worked it out by the time we stopped at Shenton, so I climbed down and found one spring hanger on the middle tender axle missing. After a telephone discussion with Adrian, we ran round and gently worked the train back to Market Bosworth, where Adrian met us and we made an unsuccessful search for the missing spring hanger. It was agreed that we would cautiously work the train back to Shackerstone where Adrian would attempt a temporary repair.

To prevent a long interruption to the service whilst the repair was carried out, it was decided that I'd 'fire-up' the Diesel Multiple Unit (DMU), running as a single-unit railcar attached to a motor car from the 2-car set). Leaving Market Bosworth on the way out, we kept a sharp look-out and, this time, located the broken spring hanger which Dave lifted on board. Dave drove the DMU back to Shackerstone since he was training to pass-out as a DMU Driver.

The DMU pauses at Market Bosworth on the way back to Shackerstone.

The DMU pauses at Market Bosworth on the way back to Shackerstone.

We disposed of the DMU on the railcar siding and returned to '3803', where Adrian had carried out a splendid repair. I've never heard of a spring hanger fracturing on a Great Western pattern tender before.

The temporary repair to the spring hanger on the middle tender axle, driver's side.

The temporary repair to the spring hanger on the middle tender axle, driver's side.

The final trip of the day was carried out with '3803'. Dave drove out to Shenton (he's also training to pass-out as a steam driver) and I drove back. A tiring, but very interesting, day.

'3803' ready for action on the last round-trip.

'3803' ready for action on the last round-trip.

My pictures

Easter 2015 at the Battlefield Line

I was rostered to drive at Peak Rail on Saturday, 21st March 2015. My previous turn on 1st March had encountered rain, sleet and snow (see report here): in contrast, the 21st March started dry but cold and during the day we enjoyed bright sun. Fate had other challenges, rather than the weather, to test Dave, the Fireman, and I. We had two one-hour Driving Experience courses before the service so it was an early start for me, even earlier for Dave.

'Lord Phil' certainly looked the part, standing on the outside pit in clean condition with plenty of polished brass on display and 'brewing up' nicely. However my priority was to oil round and carry out the daily exam. That meant the usual exercise of applying 'motion oil' to the six crankpins, the various oil boxes and oil pots, leaning in between the frames to reach the oil cups and oil holes on the motion. This usually involves climbing up onto the foot framing, dealing with the accessible oiling points, then climbing down to the ground and up again in various positions until most oil points are dealt with, leaving perhaps a few locations to be reached whilst in the pit underneath the locomotive whilst at the same time inspecting springs, motion and, well, everything.

Fireman's side Injector on an 'Austerity' ('Royal Pioneer').

Fireman's side Combined Steam and Delivery Valve and 'Klinger' Gauge Frame on an 'Austerity' ('Royal Pioneer').

There's a PDF of the Davies and Metcalfe publication 'Monitor Type Locomotive Live Steam Injector' here which will repay careful study. Relevant to 'Lord Phil' are the Combined Steam and Delivery Valve (on page 20) and the Non-Lifting Live Steam Injector 'Austerity' type (shown on page 22).

Dave knew there had been problems previously with the fireman's side injector failing to shut off properly after use resulting in steam and/or water discharging from the overflow pipe. The injector on the driver's side wasn't much better but we agreed to see how things went during the first Driving Experience course. When people are looking forward to a driving experience, may have travelled a considerable distance and, often, incurred accommodation costs, I hate to disappoint them, but, of course, safety is always the top priority. I do remember having to declare a failure on 'Royal Pioneer' when the regulator linkage in the steam dome became detached - that's described here.

We were having serious trouble with loss of water but we managed to complete the two driving experience courses and then attempted to water before the first service train, using the brown water tank at the south end of the platform only to discover that the brown tank wagon was out of water. I discussed with Gordon the easiest solution and we agreed to swop the engines round, with 'Penyghent' on the south end and 'Lord Phil' on the north end. This meant that we could reach the Grey water tank at the north end of the platform which is currently little-used. The grey water tank is much easier to use (provided you stop in the right place), because, instead of dragging a long fire hose around, there is just a hinged delivery pipe which swings across to the tank filler. This also gave a bit of variety in that we hauled the train uphill, rather than downhill, and did so bunker-first.

'Lord Phil' at Matlock, ready to haul the service train back to Rowsley.

'Lord Phil' at Matlock, ready to haul the service train back to Rowsley.

Neither Dave nor I thought the arrangements ideal but we managed to run the service all day. One or two people enquired about the locomotives being the opposite way round to normal.

Peak Rail: 'Penyghent', unusually on the south end of the train, approaches Matlock, viewed from 'Lord Phil' on the north end.

Peak Rail: 'Penyghent', unusually on the south end of the train, approaches Matlock, viewed from 'Lord Phil' on the north end.

I think this was Penyghent's 'swan song' before being taken 'Out of Traffic' for a major overhaul.

My pictures

Peak Rail 2015.

Introduction

In 1958, Myanma Railways embarked on a programme of dieselisation. The initial purchase was six diesel locomotives, after which steam locomotives were gradually phased out as more diesel locomotives were acquired. Initially, all major repairs were carried out at the existing Locomotive Workshop at Insein, Yangon. There's a report on a visit I made to Insein in the post Insein Locomotive Works. But, as the number of diesel locomotives increased, it was decided that a second workshop was required and in 1969 work commenced on a second workshop at Ywa Taung, not too far from Mandalay, initially to carry out repairs on the Diesel Hydraulic fleet of locomotives. The Ywa Taung Workshop was opened on 1st April 1975 and, over the last 40 years, has successfully expanded its role to cover repairs of Diesel Electric Locomotives and carry out staff training for both Mechanical and Electrical departments.

Ywa Taung Locomotive Workshop (Photo: Myanma Railways)

Ywa Taung Locomotive Workshop (Photo: Myanma Railways)

On 1st May 2015, I spent the day with my friend Htein Lin and his family, as described here. It was a public holiday so Ywa Taung Locomotive Workshop was closed, but I was able to discuss the work done by the Factory with the Divisional Mechanical Engineer Production.

The Main Gate at Ywa Taung Locomotive Workshop.

The Main Gate at Ywa Taung Locomotive Workshop.

Locomotives are admitted to the Works for one of three reasons:-

1. Major Overhaul (M8). This is a Heavy repair normally carried out after 24,000 hours in service.

2. Semi-Overhaul (M7). This is a Mid-life repair normally carried out after 12,000 hours in service.

3. Nominated repairs. These follow a failure in service which cannot be repaired at the running depot.

I believe the Workshop is carrying out 20 heavy repairs each year and around 100 nominated repairs (I don't have a figure for Semi-Overhaul).

Of the 665 employees at the Workshop, 472 have Basic Education, 20 have a B.Eng., 40 hold a Dip. Eng. (B Tech), 33 a Dip. Eng. (ETC) and 100 hold a B.A. in Science or Arts. The Staff Training provided at the Workshop forms an important part of Staff Development. Basic and Advanced courses are provided in Welding, Machining, Fitting, Electrical, Diesel Locomotive Repair, Electrical Repair. There is also an Electronics Course and a Technical Skills Refresher Course. Currently 160 persons are receiving training each year.

Ywa Taung Workshop produces its own Brake Blocks and Cylinder Liners.

A particular problem faced by Myanma Railways has been the long period of Myanmar's relative isolation from the rest of the world which, it is hoped, will continue to ease. One result has been an aging locomotive fleet. Out of 405 locomotives, the distribution by age is significant:-

| Quantity |

Age (yrs) |

| 220 |

over 30 |

| 71 |

20 - 30 |

| 72 |

10 - 20 |

| 42 |

under 10 |

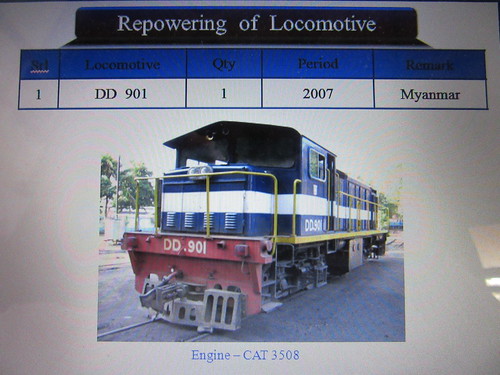

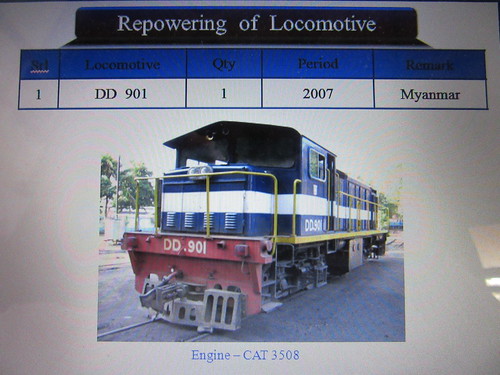

The age and diversity of the locomotives has required considerable ingenuity on the part of the railway to keep the fleet operational. Insein carries out most of the 'Re-powering' of locomotives where obsolete prime-movers need to be replaced but Ywa Taung has also demonstrated its ability to 'Re-power', fitting a CAT 3508 engine to locomotive DD901 in 2007.

Ywa Taung Workshop has 130 machine tools in use (of which only one is a CNC machine), plus a further 37 which are currently unserviceable.

A further consequence of this isolation has been the need to produce local designs using available parts for a number of special-purpose vehicles and Ywa Taung Factory has been involved in the design and manufacture of a number of special-purpose vehicles.

D1B Short Trip Locomotive

| Running number |

Build Year |

| D1B 301 |

1993 |

| D1B 302 |

1993 |

| D1B 303 |

1993 |

| D1B 304 |

1993 |

DB Shunting Locomotive

| Running number |

Build Year |

| DB 302 |

1993 |

| DB 303 |

1993 |

| DB 304 |

2011 |

| DB 305 |

2012 |

LRBE Local Rail Bus Engine

| Running number |

Build Year |

| LRBE 68 |

2003 |

| LRBE 69 |

2003 |

| LRBE 72 |

2004 |

| LRBE 73 |

2004 |

DAL

| Running number |

Build Year |

| DAL 2026 |

2000 |

| DAL 2027 |

2000 |

| DAL 2028 |

2000 |

| DAL 2029 |

2001 |

| DAL 2030 |

2002 |

| DAL 2031 |

2002 |

| DAL 2032 |

2003 |

| DAL 2033 |

2003 |

DRC Diesel Rail Car

| Running number |

Build Year |

| DRC-101 |

2001 |

| DRC-102 |

2002 |

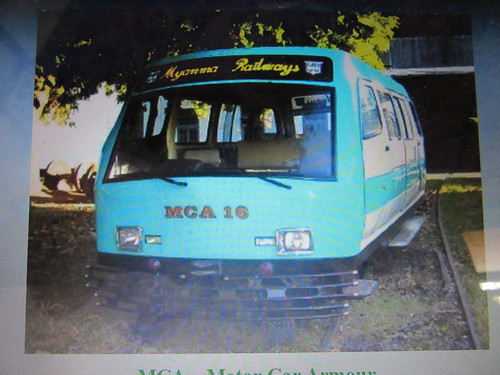

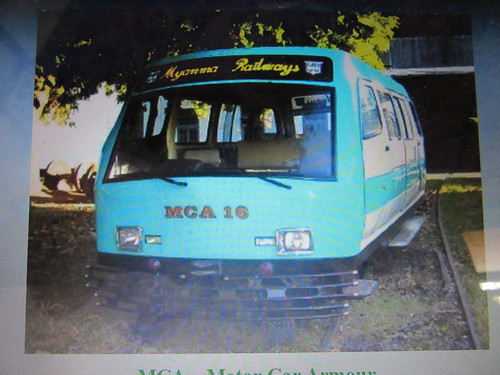

MCA Motor Car Armour

| Running number |

Build Year |

| MCA 5 |

2003 |

| MCA 16 |

2004 |

RGC Rail Gang Car

| Running number |

Build Year |

| RGC 007 |

2004 |

| RGC 008 |

2004 |

| RGC 009 |

2004 |

| RGC 010 |

2005 |

| RGC 011 |

2005 |

| RGC 012 |

2005 |

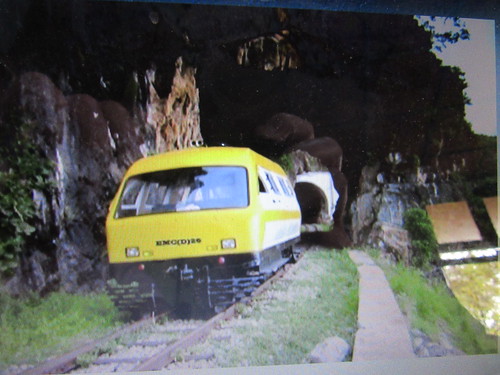

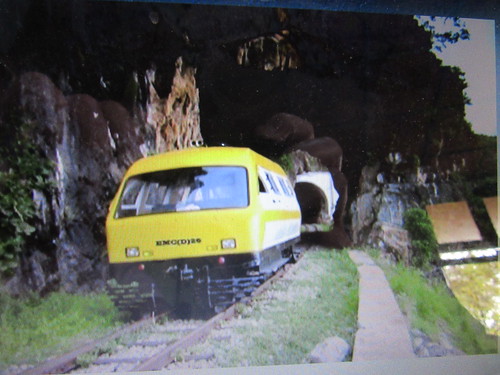

EMC Engineering Motor Car

| Running number |

Build Year |

| EMC(D) 26 |

2006 |

| EMC(D) 27 |

2006 |

| EMC(D) 28 |

2006 |

DMU Diesel Multiple Unit

| Running number |

Build Year |

| DMU-301 |

2001 |

| DMU-302 |

2002 |

| DMU-304 |

2003 |

| DMU-305 |

2004 |

Associated posts on this site

Diesel Traction in Burma.

All my posts describing railways in Myanmar can be found here.

Acknowledgments

It's impossible not to be impressed by the professionalism and dedication of all the railway employees, often working under difficult conditions to keep the trains moving. I am grateful to Myanma Railways staff for providing much of the information in this post but any errors are my own.

My pictures

The following albums (on Flickr) include pictures relevant to this post:-

Presentation on Ywa Taung Diesel Locomotive Workshop.

Ywa Taung Station & Diesel Locomotive Workshop.

All my pictures showing railways in Myanmar can be found here.

This very short introduction to trams in Rangoon is based on information from Dr. Tilman Frasch's article 'Trams in Rangoon: They first ran 100 years ago' (published in 'Tramway Review' No. 213 May 2008) and other sources.

The first tramways in Rangoon used steam trams. A successful local businessman, John Darwood had a concession to operate steam trams but, after a few unsuccessful years of operation, he sold out to a company from Calcutta. This company was equally unsuccessful and went into liquidation in 1899. John Darwood re-acquired the concession in 1902 in order to operate an electric tramway. Since all the equipment had to be imported from Britain, start-up costs were high so John Darwood sold the concession, retaining an interest, to British investors and the Rangoon Electric Tramway and Supply Company was registered in Liverpool in 1905.

The power station and headquarters were in Ahlone Township. One line ran along Dalhousie Street (now called Mahabandoola Street) to Sule Pagoda, then turning north then east along Montgomery Street (now called Bogyoke Aung San Street) to Pazundaung Jetty. A branch leading uphill along China Street served the south gate of the Shwedagon Pagoda. The system was further extended up until the mid 1930s, by which time it was carrying over 40 million passengers a year. For a better idea of the street layout, you can refer to the Rangoon Guide Map of 1930 (published under the direction of Brigadier R. H. Thomas D.S.O., Surveyor General of India). There's a series of photographs showing parts of this map here.

Dr. Tilman Frasch reports that, in 1909, a special, decorated trailer was introduced for the purpose of carrying coffins.

A marvellous postcard of an electric tram at the Shwedagon tram terminus in the 1920s.

This postcard appears on an interesting blog page here which describes the life of businessman and philanthropist Sir Adamjee Haji Dawood (1880-1948) who was a director of the Rangoon Electric Tramway and Supply Company.

Tram Views of Asia gives the following succinct description of the system:-

Rangoon is the capital, commercial center and principal seaport of Burma. Site of an ancient Buddhist shrine, the gold-covered Shwe Dagon Pagoda, the area was occupied by the British in 1824 and became Burma's capital in 1852. The British built large public buildings, parks and gardens and opened a system of steam tramways in 1884. An electric tram system followed on Dec. 15, 1906, and by 1921 there were 22 km of track and 77 cars in operation. Japanese air raids destroyed the power plant during World War II. The postcard below shows Buddhist monks setting out on a tram to collect alms. Another card in this series shows their return.

Another view of the Shwedagon tram terminus (Photo: Tram Views of Asia)

The other part of the company's business was providing electric street lighting and electricity for commercial and private use. The Municipal Commissioners decided that electricity generation and transmission should be under their control and, in 1937, a municipal power station was opened. This was destroyed in 1942 during Japanese air raids on Rangoon. Later, the Rangoon Electric Tramway power station was destroyed by the British to deny the facility to the advancing Japanese. The Japanese were able to bring the municipal power station back into use until 1944 when they destroyed it in the face of Britain's re-occupation. After the war, limited generation was not resumed until 1950.

The Rangoon Electric Tramway was nationalised as part of the Rangoon Electricity Supply Board in 1953 and, following prolonged wrangling over compensation for the shareholders, the Rangoon Electric Tramway was dissolved in 1961.

Book references

'Electric traction in the Burmese capital: A history of the Rangoon Electric Tramway and Supply Company, Limited' by Robert Sechler: published in 2000, Los Angeles.

Overall description

Myanma Railways are committed to a number of projects to build new railways to improve communications in Myanmar. One of these projects is providing a railway line from Katha (on the west bank of the Ayeyarwaddy River) to Bhamo (further north, on the east bank of the Ayeyarwaddy River).

Katha is already served by an existing branch line from the junction at Naba with the line from Mandalay to Myitkyina in Kachin State.

The line from Katha to Bhamo was started in May, 2007. The work is divided into three sections: Katha-Kyautkyi (length 37.06 miles), Kyautkyi-Simkhan (28.26 miles) and Simkhan-Bhamo (29.56 miles), giving a total length of 94.88 miles.

Section 1. Katha - Kyautkyi: The line from Katha to Moe Tar Kyi line opened on 20th October 2010 and from Moe Tar Kyi to Kyautkyi line on 7th February 2014. There are 141 bridges in this section. 132 bridges have a span of less than 40 feet, 8 bridges have a span between 40 and 180 feet and one bridge has a span exceeding 180 feet.

The line is controlled by the following Block Stations: Katha, Paw Ma Myaing, Min Le, Moe Tar Kyi, Choung Wa and Kyautkyi. These stations are provided with fixed distant signals and working Outer Signals. Block Working uses paper 'Line Clear' forms.

A regular passenger service is now operated on this section by diesel railcars type RBE (brief details in the post Diesel Railcars in Burma). The Line Speed Limit is currently 15 miles/hour. The line from Katha to Choung Wa is in Sagaing Division: beyond Choung Wa, the line is in Kachin State.

Kyaukkyi Station, Myanmar (Photo: Htein Lin)

Kyaukkyi Station, Myanmar (Photo: Htein Lin)

Section 2. Kyautkyi - Simkhan: This section has 129 bridges, all completed. This section will have Block Stations at Myo Kone and Simkhan. Stations and signals will be similar to section 1.

Section 3. At Simkhan, a major road/rail bridge across the Ayeyarwaddy River has been built. The remainder of section 3 to Bhamo is under construction.

The new junctions at Katha

I've made two round trips from Katha to Naba, both times on special trains operated in connection with 'Road to Mandalay' river cruises. The first railway trip was in 2010 (when I travelled in the locomotive cab) and those journeys are described in the (technical) posts Cab Ride from Katha and Cab Ride back to Katha. Two years later, I repeated the trip, described in the post By Train to Naba. Each of these posts has links to the associated photographs.

On the first railway trip in 2010, I was intrigued to discover an unexpected triangular railway junction about 3.5 km from the terminus at Katha.

The photograph below was taken from the locomotive cab on the return journey from Naba to Katha in 2010 shows the new line to Bhamo trailing off to the left. There is a handsignalman, the usual single lever to operate the junction points which are then secured with a point clip. 'Stop' signals are provided but were not operated - the handsignalman giving a Green Flag as authority to proceed. The bamboo shelter at the junction appears to be for the handsignalman's use.

The new junction viewed from a train on the Naba to Katha line, looking towards Katha showing the new line to Bhamo trailing off to the left.

The new junction viewed from a train on the Naba to Katha line, looking towards Katha showing the new line to Bhamo trailing off to the left.

The photograph below, taken from the train on the Naba to Katha line in 2012, shows the new line to Bhamo curving away to the right. Note the single point lever controlling 'trap' points which, when open as in the picture, will derail any vehicles approaching the junction from the new line, providing 'flank' protection to a train on the Naba to Katha Line. A 'Stop' signal is also provided.

The new line to Bhamo curving away to the right, viewed from a train on the Naba to Katha line.

The new line to Bhamo curving away to the right, viewed from a train on the Naba to Katha line.

The photograph below, taken from the train on the Naba to Katha line in 2012, shows the 'third side' of the triangle, which would allow a train from Naba to divert towards Bhamo, rather than proceeding to Katha. Note mix of timber and concrete sleepers. The undergrowth between the rails testifies to the line not being in regular use.

The 'third side' of the triangle, viewed from a train on the Naba to Katha line.

The 'third side' of the triangle, viewed from a train on the Naba to Katha line.

The new bridge at Simkhan

In 2012, I visited Bhamo on the 'Road to Mandalay' cruise ship and I took the photographs below of the Simkhan bridge, commenting:-

"We passed under the New Bridge which appears almost complete. There are eight steel truss spans but only the one we used was marked for river traffic. There were 'traffic lights' on the bridge piers but they were not lit. The bridge carried a lane for road traffic (equipped with lighting standards), a single track metre gauge railway and a pedestrian lane. On either side of the bridge spans, there are reinforced concrete approach viaducts. I was told that the railway track on the west bank will be connected to the triangular junction at Katha and will be extended to Bhamo on the east bank."

The Simkhan Road/Rail Bridge, Ayeyarwaddy River.

The Simkhan Road/Rail Bridge, Ayeyarwaddy River.

West bank of the Ayeyarwaddy River, showing the Simkhan Road/Rail Bridge.

West bank of the Ayeyarwaddy River, showing the Simkhan Road/Rail Bridge.

Rails stockpiled, awaiting use: Simkhan Road/Rail Bridge, Ayeyarwaddy River.

Rails stockpiled, awaiting use: Simkhan Road/Rail Bridge, Ayeyarwaddy River.

Acknowledgments

I am grateful to Myanma Railways staff for providing much of the information in this post but any errors are my own.

Related posts on this website

I've made two visits to Bhamo by river (on the 'Road to Mandalay' cruise ship) in 2010 and again in 2012. There are a number of (non-technical) posts on these trips - those for 2010 are here and those for 2012 are here. These posts have links to photograph albums where there are more pictures of the railways and river bridge.

View of Rowsley station car park as 'Lord Phil' sets off for Matlock Town.

View of Rowsley station car park as 'Lord Phil' sets off for Matlock Town.

Preserved Chesterfield bus passes over the level crossing at Darley Dale.

Preserved Chesterfield bus passes over the level crossing at Darley Dale.

2-car train of Class 156 units arriving at Matlock Town.

2-car train of Class 156 units arriving at Matlock Town.

'Lord Phil' stands on the pit outside the engine shed.

'Lord Phil' stands on the pit outside the engine shed.