Events of Saturday 28th December 2019

I was asked to drive on Saturday 28th December 2019, once again on 6989 'Wightwick Hall'. I discovered Stephen W. was my fireman and that he'd gone in on Friday evening to light a warming fire, returned home for a few hours sleep and arrived back at the shed shortly after me. Stephen was happy setting a new fire, so I turned to the oiling round.

Click for larger view

'Modified Hall' Class from British Locomotive Types 1946 (Railway Publishing Co. Ltd.)

The 2-cylinder 'Standard' designs of the Great Western with outside cylinders have Stephenson Link motion with four eccentrics mounted on the driving axle between the frames to provide the necessary valve events. Inside cylinder Great Western designs normally have valves between the frames which can be directly driven from the expansion links between the frames. But with outside cylinders and valves, as used on the 'Hall', rocking shafts are required to transmit the movement of the dieblocks between the frames (via the intermediate valve rod, rocking shaft, valve link and valve rod) to the piston valves outside the frames.

This is illustrated in the well-known diagram below, taken from the 'Handbook for Railway Steam Locomotive Enginemen', published by the British Transport Commission in 1957. Original copies are still available on the second-hand market and an Ian Allan reprint from 2014 is available new (ISBN: 9780711037946).

Click on the above diagram to enlarge.

Click on the above diagram to enlarge.Layout of valve gear.

I could get at most of the outside motion but the corks on both little ends were inaccessible.

Six portable, cylindrical oil pots each with a shut-off cock feeding a flexible, plastic hose are provided for the important job of topping up the coupled wheel axleboxes. The idea is that the oil pots clamp on the foot-framing with each hose fed to the filler on top of the axlebox. This involves reaching through the spokes of the coupled wheels to access the filler tubes but, again, the angle at which the engine had stopped meant that this oiling had to be deferred until we'd sufficient steam to move to a better position.

The engine was partly over the pit but not in a very good position. A bigger problem was the fact that after a number of days of intensive two-train 'Santa' services, one half of the length of the pit (the half I needed to work in, naturally) was fairly full of ash. This, combined with the fact that it's a rather shallow pit in any case, meant that scrambling around in the pit, ducking under the brake gear, was quite challenging. Having hauled myself up in the space between the dual brake shafts so as to stand on the brake rigging, facing the firebox, I was able to deal with the large-capacity oil reservoirs on the four eccentrics. The two pictures below show the driving axle with its eccentrics.

View of Driving axle showing (L-R) Right Fore Eccentric, Right Back Eccentric (6989 'Whitwick Hall')

View looking rearwards showing driving axle with left fore eccentric and front of outer firebox. The oil feeder and wiper gives an idea of the generous proportions of the axlebox (6989 'Whitwick Hall')

Still perched on the brake rigging, I turned round to face forwards, allowing me to attend to the oiling points associated with the expansion links and lifting links.

View looking forward showing left expansion link, arm on weighshaft to operate left lifting link and left dieblock which is connected to the fluted intermediate valve rod extending forward to the inner valve arm of the rocking shaft. Leading coupled axle in background (6989 'Whitwick Hall')

View looking forward with left lifting link just visible. The fluted intermediate valve rods lie almost horizontal either side, connected beyond the frame stretcher to the inner valve arms of the rocking shafts. Note the large vacuum brake cylinder between the frames ahead of the leading coupled axle. The red-painted pressed metal guards bolted to the axleboxes of the coupled wheels are provided to screen the journals from foreign matter (6989 'Whitwick Hall')

Having completed this part of the oiling, I gingerly lowered myself down into the pit between the twin horizontal brake shafts and completed oiling the leading bogie.

View looking forward and down while perched on brake rigging ahead of driving axle, showing the twin longitudinal brake shafts with bottlescrew adjusters (6989 'Whitwick Hall')

The 'Churchward era' 4-6-0s introduced bar-framed bogie trucks and I think these were used on the original 'Halls'. But Hawksworth's 'Modified Halls' substituted plate-framed bogies. More drastically, Hawksworth introduced plate main frames throughout on the 'Modified Halls'. Earlier locomotives based on Churchward's preferences had plate main frames as far forward as the cylinders which were manufactured using two castings bolted back-to back on the centre line of the locomotive incorporating steam exhaust passages and smokebox saddle. Adopting back-to-back cylinder construction required bar framing between the cylinders and the front buffer beam. The 'Modified Hall' had two separate cylinder castings conventionally bolted to the outside of plate frames running the length of the locomotive. I suspect (but haven't been able to confirm) that the motive for these changes was cost-saving.

With steam pressure in the boiler rising, we moved the locomotive so that the coupled wheel axleboxes and little ends could be dealt with. Stephen attended to the axleboxes whilst I clambered up on to the front framing to top-up the oil pots on the rocking shafts and the other oil pots. The vacuum pump oil pot on the driver's side is accessible through a cut-out in the foot framing. This uses a mix of cylinder oil and paraffin to preventing 'sticking valves' on the pump.

6989 'Wightwick Hall': Right leading splasher showing cut-out in foot framing giving access to the vacuum pump oil pot (Battlefield Line Santa Specials 2019)

6989 is fitted with a hopper ashpan operated by large lever or 'key' normally stowed in the cab on the fireman's side. To empty the ashpans, the 'key' is engaged with a square-section shaft accessible through a cut-out in the footplate steps on the fireman's side, and the locking pin (rather hidden behind the footplate steps) is removed. The key can then be operated back-and-forth through a wide arc, opening and closing the hopper doors until all the ash has been dislodged and dropped into the pit. Even using the ashpan spray connected to the fireman's side injector, this usually results in plenty of ash flying around. Finally, the hopper doors are closed, the securing pin is replaced and the heavy 'key' stowed back in the cab.

Stephen operating the hopper ashpan (6989 'Whitwick Hall')

6989 'Whitwick Hall' 'brewing up' in the shed at Shackerstone, prior to working 'Mince Pie Specials' (6989 'Whitwick Hall')

We'd raised sufficient pressure to move outside the shed and a quick test of the vacuum brake showed that we'd enough brake power to move safely across to our 5-coach train in platform 2 so that we could start steam heating the coaches.

Our diagram called for four round trips to Shenton during the day, leaving Shackerstone at 11:00, 12:30, 14:00 and 15:30

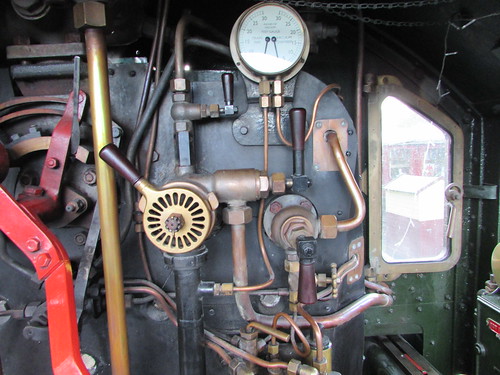

The view below shows the standardised layout of the driving controls on the right side of the cab.

6989 'Wightwick Hall': Driver's vacuum brake application valve with small ejector steam cock (above), large ejector steam cock (right) and blower valve (below right)

Of course, when in motion, most of the driver's attention is focussed ahead. The Christmas Fairy Lights were still in place on 6989, as a further distraction. The You Tube clip below shows how limited the view from inside the cab can be, which I why I tend to prefer to lean out over the cab side sheeting most of the time. Click 'Replay' to watch again.

Driver's view ahead on 6989 'Whitwick Hall' between Market Bosworth and Shenton on the Battlefield Line on a 'Mince Pie Special' service on 28th December 2019.

At each end of the line, we ran round the train and Stephen commented that there's not much room for the fireman to work in when coupling up once the locomotive had 'squeezed up'on its train.

There's not much room for the fireman to work in when coupling up once the locomotive has 'squeezed up'on its train (6989 'Whitwick Hall')

During the afternoon, we decided to 'top up' the tender tank from the column at Shackerstone. It was already getting dusk when I took this last view of 'Wightwick Hall' ready to leave Shackerstone with a 'Mince Pie Special'.

6989 'Whitwick Hall' ready to leave Shackerstone with a 'Mince Pie Special'.

Passenger numbers had been encouraging all day, Stephen had kept a good fire and we were both satisfied when we completed the last trip and disposed the locomotive after an enjoyable day.

Related posts on other websites

The 6989 "Wightwick Hall" Restoration Group.

Related posts on this website

Santa Specials at the Battlefield Line 2019

(Part of this post describes working on 'Wightwick Hall')

All my Battlefield Line posts.

My photograph albums

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures may be selected, viewed or downloaded, in various sizes, from the albums listed:-

Battlefield Line 'Santa' trains 2019.

6989 'Wightwick Hall'.

All my Battlefield Line pictures.