The post The World of Work described my introduction to industrial electronics when I worked at Contactor Switchgear (Electronics) Limited in Wolverhampton.

This cast nameplate (in various sizes) was attached to panels made by Contactor Switchgear Limited (Photo: Wolverhampton History and Heritage Website).

In 1966, I decided to set-up on my own, and the post Starting my own business describes the initial slow progress, producing industrial control equipment for a few clients before my former employers asked if I could design and build a Ships Movement Indicator for Dover Harbour Board. With help from friends who had also moved on from Contactor Switchgear(Electronics) Limited, we produced the remarkable affair and commissioned it in the windswept Dover Harbour Port Control building on the Eastern Arm breakwater projecting into the English Channel. The specifiers of the equipment had not troubled to ask the users what they needed resulting in the equipment being unloved by the people it was intended to help and it was removed after a few years service. Later in my career, I learnt that the Ships Movement Indicator project was by no means unique in failing to determine the real needs of the intended users. I'd invested so much energy in doing the best job I could, when the redundant system was offered at scrap price, I bought the equipment back and it still moulders in storage.

The above post Starting my own business also describes the selective call equipment we produced for Gerry Gardner for use over private mobile radio. This work was more successful and I learnt a lot from our gruff, rather eccentric client. I also experienced my first flight, described My First Flight.

I managed a few more light aircraft trips in connection with the business. starting with a flight to a steelworks on Teesside, described here. This resulted in our producing Electronic Vibratory Feeder equipment for a number of steelworks on Teesside and elsewhere. There's an introductory article on my association with steelmaking here but I hope to recount more experiences in the future.

In those early days, we produced a few small railway telephone systems. Two were for the Kowloon-Canton Railway: one (for ML Engineering) which they installed at the Hung Hom terminus in Hong Kong and, later, one (for Westinghouse Brake and Signal) for Sha Tin. Westinghouse Brake and Signal also ordered small railway telephone systems for use at the modernised steelworks at Redcar and Ravenscraig.

In 1970, based on the success of our selective call equipment for Gerry Gardner, British Rail approached us about the possible supply of selective call telephone equipment for use over wire. This was in connection with the electrification between Crewe and Carlisle. The above post Starting my own business includes a brief account of this period. Up to around 1980, we periodically received further orders for this equipment, involving large numbers of waterproof trackside telephones and electronic equipment racks at the Power Signal Boxes at Warrington, Preston and Carlsle.

Carlisle Power Signal Box.

Westinghouse Brake and Signal gave us an order in 1972 for a new design of selective call telephone equipment for use on the Centralised Traffic Control (CTC) scheme between Dublin and Ballybrophy in the Republic of Ireland. Various staff from Ford Electronics, including the writer, made a number of trips to Eire during the installation and commissioning phases. It was an interesting time which I've not yet described and, at the moment, there are no pictures.

Around that time, we also produced electronic Signal Post Telephone (SPT) equipment which was installed in Northern Ireland, a few locations on British Rail and at one or two Power Stations.

The original selective call telephone systems for British Rail were fairly successful, leading to further development resulting in an enhanced version with multi-party conference capability for use as Electrification Telephones. This equipment is outlined in the post Electrification Telephone Systems for British Rail. Altogether, we supplied equipment for three installations of this type of system for London Midland, Scottish and Eastern Regions of British Rail. This, and sub-contract manufacture of other telecommunications equipment for British Rail kept us busy for a few years.

In 1976, we negotiated a large order from G.E.C. to supply a specially-designed selective call telephone system for use on the Trunk Line Electrification Project in Taiwan. I learned many valuable lessons working for G.E.C. which I talk about in the post Working for the Big Boys. The G.E.C. order included modular telephone concentrators and a large number of trackside Wayside Telephone boxes mounting a multi-circuit telephone and disconnection terminals for the lineside telephone cables. On this project, the consultants were German so, in the design stages during 1976, that gave me a couple of visits to Frankfurt. Commissioning and resolving problems which arose with the selective call system resulted in my making, I think, three visits to Taiwan during 1977 and 1978. There are no technical reports at present but my vivid impressions on my first visit to Taiwan are in the post My first visit to Taiwan. We received further orders for this equipment in 1981, 1988, 1990 and 1991.

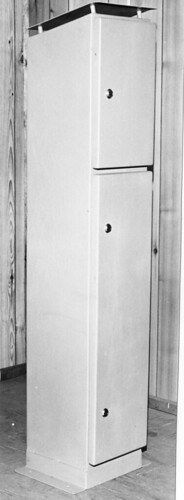

Housing for trackside Wayside Telephone: The upper compartment mounts a multi-circuit telephone, the lower compartment is used for cable termination, equipment mounting and power supplies.

Canadian Aid funded an interesting railway traffic control system for Malawi in 1977. We produced what we thought was a neat electronic version of the venerable Western Electric electromechanical impulse selective telephone equipment. Standard Telephones and Cables produced electromechanical equipment similar to the Western Electric equipment for a time and adapted the signalling principles in their electromechanical Signal Post Telephone equipment widely used on British Rail. Despite the elegance of our system, we didn't have much commercial success.

By this time, I seemed to have gained some sort of reputation and I was flattered when the mighty Philips invited me to do some consultancy work on railway telecommunications in 1980. This interesting period is touched on in the post Working in Holland.

Iraq were building a new railway linking Mosul, Kirkuk and Haditha (at that time, oil-rich Iraq was regarded as an attractive client although I had my doubts). Philips were bidding to the Korean firm Hyundai for the telecommunications package for the railway but they ultimately walked away, convinced they couldn't make a profit at the price Hyundai was prepared to pay. There's a report here. Despite some disappointment, the wisdom of their decision was not lost on me and when, some months later, G.E.C. offered me a large sub-contract for the same project although we were short of work I declined. As I watched G.E.C. lose significant sums of money on the scheme and their chosen sub-contractor fall into bankruptcy, I regarded my decision as one of the best I'd made.

We produced another large system of railway selective call telephone equipment for G.E.C. in 1985, when the Ferrovia do Aco in Brazil was electrified to bring iron ore from the mountains near Belo Horizonte down to the deep-water port at Sepetiba. It had been arranged that I would visit Brazil in connection with the commissioning but, to my disappointment, it didn't prove necessary and my first visit to Brazil was not until 2005 (forming part of the trip 'Round the World 2': e-mails sent to friends from that trip were subsequently converted to the blog post here). We received a further order for test equipment for use on the Brazil system in 1991.

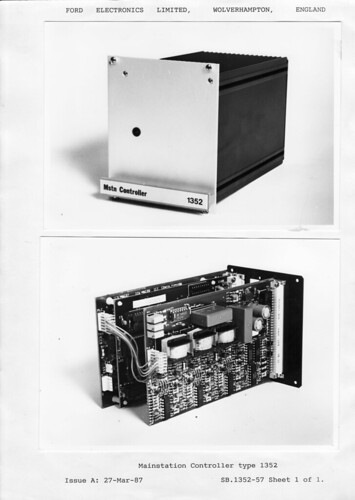

Mainstation Controller type 1352 is part of the system supplied to the Ferrovia do Aco. The rugged aluminium module housing is common to the whole range. The lower view shows the printed circuits assembled onto the back panel with the case removed.

In 1987, we did an interesting project with STC Telecommunications who, by then, were part of Northern Telecomm in which we licensed one of our selective telephone system designs, allowing STC Telecommunications to procure and build the equipment at their manufacturing site in South Wales. The equipment was to re-equip the Suburban railway network around Mumbai (which, back then, was still called Bombay). I didn't get to visit India during that commissioning, either, so my first trip to India was in 1992, in connection with commissioning equipment for the Delhi Ring (described later in this report).

G.E.C. bid on a project in 1987 to replace ageing electromechanical Train Despatcher Telephone Systems throughout Thailand. The equipment being replaced was impulse-selective equipment built by Standard Telephones and Cables in England of the pattern mentioned in the paragraph on Malawi above. The project was being funded by Japan so the consultants were Japanese and the specification had been very tightly-drafted in a way that made it very difficult to offer a compliant bid. There were many ups and downs on this project, not least because G.E.C. had seriously underestimated the costs of installation and commissioning in Thailand. For many months, we had an engineer based in Thailand, providing technical assistance to G.E.C. and training Thai Railways staff. I also made five visits in 1988 and 1989 during which I travelled widely around the country. At the completion of the project, G.E.C. held an 'I & C Seminar' in Bangkok which has a report here, with links to my pictures (scanned from 35mm prints).

Train Despatcher Equipment for Thailand under test in Wolverhampton.

When G.E.C. provided telecommunications systems for the Delhi Ring resignalling project, they decided to contract another company for the selective call telephones. However, serious problems were experienced with speech quality when the system was installed in 1992 and we were asked to urgently look at the problem. We didn't see a major difficulties with the basic selective call telephone system but the problems in transmitting over a complex loaded cable network had not been fully understood. We re-designed the audio transmission, using a network of 2-wire adaptive audio repeaters with programmable build-out for use on loaded lines and associated battery-backed power supplies. I was in India almost seven weeks installing and commissioning our modifications. There's a short post here with a link to a more detailed report.

In 1993 G.E.C. asked us to quote for Tunnel Telephone Equipment for the new Jubilee Line Extension Project. None of our existing designs of telephone system seemed adaptable - the major function of the Tunnel Telephone system is to provide a highly-dependable emergency shutdown system for the traction current. I recommended that they try Westinghouse (who had, I'd found out, previously supplied tunnel telephone equipment for the Central Line). A few months later, G.E.C. repeated the request and this time we agreed to quote. We supplied the equipment for the Jubilee Line Extension and we're still occasionally supplying tunnel telephone equipment for use on London Underground. There's more in the post London Underground and Jan.

Tunnel Telephone Cubicles for Northern Line under test in Brewood.

More when I can.

Related posts on this website

For ease of reference, this list duplicates links in the above text.

Work.

The World of Work.

Starting my own business.

My First Flight.

here.

Visiting Steelworks.

Electrification Telephone Systems for British Rail.

Working for the Big Boys.

My first visit to Taiwan.

Working in Holland.

Visit to Seoul, South Korea.

Round The World Two.

Train Dispatcher Project - Thailand.

My first trip to India.

London Underground and Jan.