There is an earlier post which introduces the role of the shunter here and the comments on safety in that post equally apply here. The introductory post discussed simpler coupling systems widely used on standard-gauge freight rolling stock. This part discusses couplings used on passenger rolling stock.

Screw Couplings

Whilst the 'loose coupling' provided by three-link couplings was acceptable on freight trains, passenger vehicles needed to be more tightly coupled to give a reasonable level of comfort. For many years, passenger coaches in Britain used 'screw-couplings'.

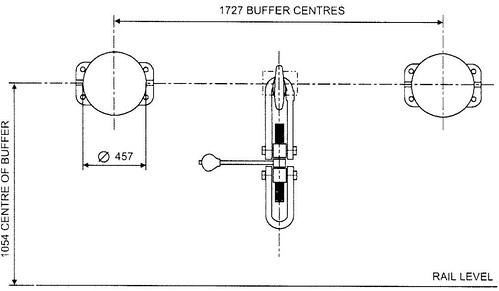

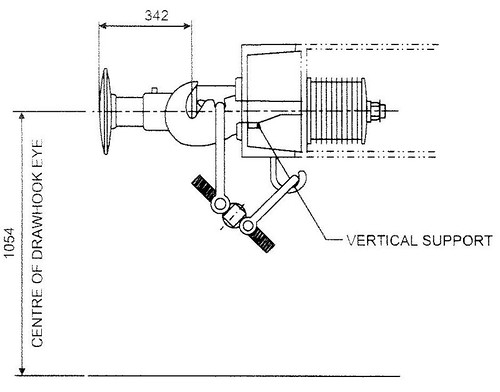

Vehicle with Screw Coupling hanging: End view (from a Railtrack document).

Vehicle with Screw Coupling stowed on hook: Side view (from a Railtrack document).

Vehicle with Screw Coupling stowed on hook: Side view (from a Railtrack document).

Once the coupling is on the drawhook of the adjacent vehicle, it is tightened up by rotating a threaded screw which has one end with a left-hand thread, the other end with a right-hand thread, using a built-in tommy bar incorporating a counterweight. This draws the two D-links together tightening the coupling so that, on straight track, the buffers will be equally compressed but, on curves, the buffers on the inside of the curve will be further compressed and the buffers on the outside of the curve will slacken slightly. At all times, the buffers should remain under some compression, so that the train cannot bang in and out. The comfort of the passengers depends upon the screw adjustment being correctly carried out. The complete process of coupling vehicles is outlined in the article On the Footplate (Part 2).

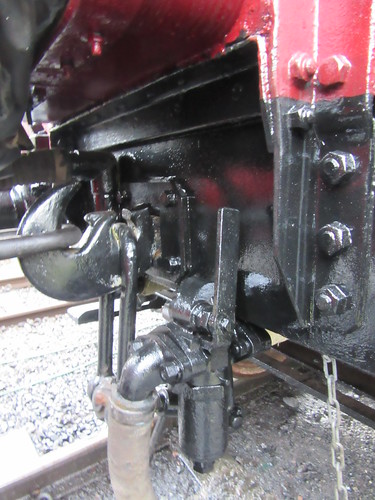

The picture below shows restored L.M.S. coach 7828 attached to 'Austerity' Tank 'Lord Phil' at Peak Rail.

Restored coach 7828 at Rowsley: View showing coach drawhook, with unused coach 'D' link hanging down. The rest of the stowed coach screw coupling is obscured by the steam heating hose. The coach has been attached to 'Austerity' Tank 'Lord Phil' using the locomotive coupling.

Although screw couplings were effective, the results of accidents, particularly at higher speeds, showed the limitations of screw couplings. Part of the train could twist or even break free, increasing the chance of serious injuries.

Automatic Couplings

In other countries, various forms of 'Automatic' coupling had been developed to provide extra strength and simplify the business of coupling and uncoupling vehicles. In America, Eli Janney patented his design in 1873 and, in 1893, legislation made this the standard coupling in America. In 1915, John Willison of Derby patented his own automatic coupling which, with modifications, was adopted in 1935 by the Soviet Union as their standard coupler.

Ukraine Steam: Locomotive Em 735-72 at speed in the rain, showing Russian pattern autocoupler between tender & coach.

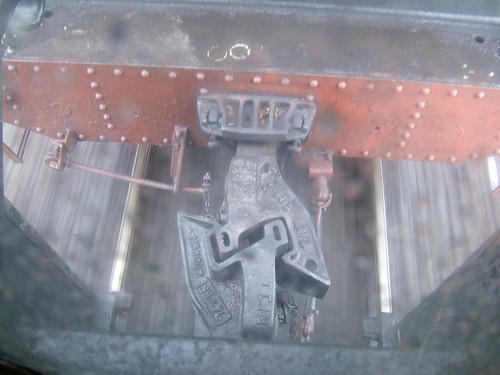

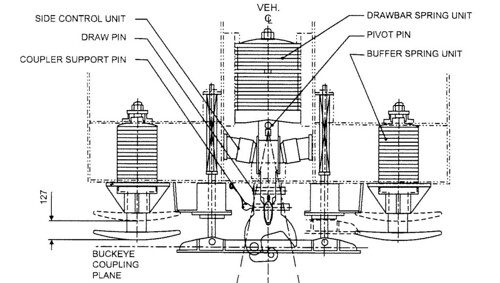

A variation of the Janney coupling with side release called the 'Buckeye' was adopted by the L.N.E.R. and the Southern in the 1930s, retaining side buffers. Since not all vehicles were fitted with 'Buckeye' couplings (and only one class of British steam locomotives was fitted - Gresley's 'A4'), the 'Buckeye' fitted to coaches was a 'drophead' pattern where the automatic coupler head could be lowered to reveal a conventional drawhook for use with a screw coupling. After the 1948 Nationalisation of British railways, a range of standard passenger coaches were built, similarly fitted with a conventional drawhook, 'drophead' 'Buckeye' coupler and adjustable side buffers (each with two positions - 'long' for use with a conventional screw coupling and 'short' when using the 'Buckeye').

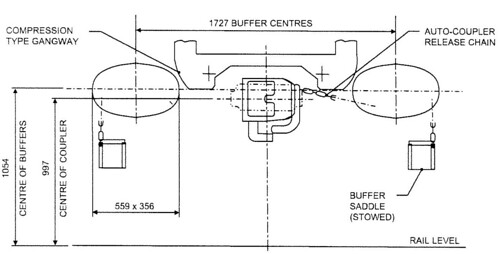

Buckeye Coupling as fitted to B.R. Mk 1 and Mk 2 gangwayed vehicles: End view (from a Railtrack document).

Buckeye Coupling as fitted to B.R. Mk 1 and Mk 2 gangwayed vehicles: Top view (from a Railtrack document).

Buckeye Coupling as fitted to B.R. Mk 1 and Mk 2 gangwayed vehicles: Side view (from a Railtrack document).

The 'Buckeye' has a substantial hinging 'knuckle'. To couple, two vehicles are brought together with one of the knuckles in the 'open' position and the adjustable buffers set to the 'Short' position, as shown in the picture below.

BR Coaches being shunted together. Buffers in 'Short' position for use with Buckeye coupling. Unused 'saddles' are stowed on a bracket adjacent to each buffer.

As the two couplings contact, the open knuckle is forced closed and a mechanical latch drops, locking the knuckle closed. In addition to the shunter confirming visually that the 'pin' has dropped, a 'pull test' is conducted where the locomotive tries to separate the vehicles.

To uncouple, pulling a chain on either coupling head unlatches that knuckle, allowing the knuckle to swing open and the vehicles to be drawn apart.

When coupling or uncoupling the shunter stands alongside the vehicles and controls the movement by hand signals given to the driver of the locomotive performing the shunt. Unfortunately, to connect or disconnect the brake hoses and, when required, the steam heating hoses, the shunter still has to clamber underneath the vehicles, after coming to a clear understanding with the driver that it is safe to do so. The electrical jumpers between vehicles which allow the guard to control the carriage lighting also require connection/disdconnection.

Related posts on this website

The Role of the Shunter (Part 1).

On the Footplate (Part 2).

MIC - Brakes.

Mutual Improvement Classes (2) (List of MIC posts).

My photograph albums

Where necessary, clicking on an image above will display an 'uncropped' view or, alternately, pictures from may be selected, viewed or downloaded, in various sizes, from the albums listed:-

Passenger Rolling Stock.

['Related posts' amended 13-Apr-2020]