skip to main |

skip to sidebar

Over the years, the reciprocating steam engine has appeared in many forms. None is more unusual than the Oscillating Cylinder Engine. As the name suggests, the cylinder is arranged so as to pivot on the mounting frame. The piston rod connects directly to the crank, causing the whole cylinder to swing to and fro. The abutting mounting faces of the cylinder and mounting frame are provided with ports so that the movement of the cylinder opens and closes the appropriate ports to admit and exhaust steam at the correct time without the necessity for valve motion. Wikipedia has an article here which outlines some early industrial applications for this design.

Many people were introduced to oscillating cylinder engines through their use in live-steam toys made by 'Mamod'. Although I never had one of the models, I was fascinated by the simplicity of construction. I didn't realise how extensive the 'Mamod' range was until I read the Wikipedia article here.

In May 2011, my Friend Keith visited the U.K. and, on a visit to Peak Rail, we studied the 'vacuum motor'. This is powered by an Oscillating Cylinder Engine operating on vacuum from the locomotive’s braking system and, through suitable reduction gearing, can effortlessly turn the largest locomotive. There's a collection of pictures here.

On 13th February 2013 I visited Keith at his home in Perth, Western Australia. Keith had always been impressed with the simplicity of the ‘Oscillating Cylinder’ engine and he ran (on compressed air) an ‘Oscillating Cylinder’ engine he built many years ago to demonstrate how powerful this type of engine can be when properly engineered. There's a description of this part of my visit here.

Keith's demonstration 'Oscillating Cylinder' engine.

It wasn't until September 2015, when I was preparing the post Railway Turntables that I found that Messrs. Cowans, Sheldon & Co. Ltd. of Carlisle held a patent for this method of driving turntables by either vacuum or air from the braking system of the locomotive being turned.

Introduction

In 1971, I acquired Brewood Hall. It was in a fairly sorry state but, having done what repairs and redecorations could be afforded at the time, it became my family home. Over the years, more extensive conservation and redecoration work has been carried out as possible.

I started to research the history of the Hall and produced a small pamphlet summarising my findings (printed using an obsolete type of stencil duplicator called a 'Gestetner'). Early in 2008, this information was transposed into the internet posting here. As time permitted, I've carried out more historical research, assisted by friends.

This post is a collection of more recent findings. Historical information frequently contains errors, for a variety of reasons. Transcription errors may occur - particularly with old documents. Many books 'borrow' from other sources, with or without acknowledgement, sometimes allowing errors to perpetuate. Writers should cite the sources for information quoted, so that readers can form a view as to its likely accuracy. I'm afraid this rigour has not (yet) been applied to these notes, in the interests of assembling the information I've come across in one place, but there is an informal Bibliography at the end. Brewood Hall was always a rather minor estate so not too much information is recorded. Little is known with complete certainty.

The Victoria County History (often referred to simply as 'VCH') was founded in 1899, dedicated to Queen Victoria, and intended as "an encyclopaedic record of England's places and people from earliest times to the present day". Since 1933, it has been based at the Institute of Historical Research, University of London, modestly claiming to be "without doubt the greatest publishing project in English local history." The VCH covers most of England and is organised on a county basis. Staffordshire (in which Brewood is located) is covered in 14 volumes! Brewood appears in Volume 5, covering the East Cuttlestone hundred (the 'hundred' is an archaic county division, described in Wikipedia here). Fortunately, a digital version of this information is available at British History Online which was founded in 2003 by the Institute of Historical Research and the History of Parliament Trust, to provide "a digital library of key printed primary and secondary sources for the history of Britain and Ireland, with a primary focus on the period between 1300 and 1800".

The index for the digital version of the 'A History of the County of Stafford: Volume 5, East Cuttlestone Hundred' is here. The two sections most relevant to Brewood are:-

Brewood: Introduction, manors and agriculture

Brewood: Churches, schools and charities

Some information is held at the Staffordshire Record Office and the William Salt Library, both located in Stafford.

A summer evening at Brewood Hall in 2015.

A summer evening at Brewood Hall in 2015.

Miscellaneous Notes

Hearth Tax

In the Hearth Tax Assessment of 1666, Brewood Hall was assessed at 10 hearths. There's an explanation of Hearth Tax here. Roehampton University, London runs the Centre for Hearth Tax Research and they maintain an on-line database at Hearth Tax Online covering some parts of England (but not Staffordshire).

Gardens and Orchards

Brewood Hall was a 'manor peculiar' without extensive land. Until the 1960s, there were about six acres of gardens and orchards. Following the sale to a property development company, around 5 acres were developed for housing, leaving about one acre with the Hall. Dr. Plot visited Brewood Hall, writing in 1686 that "In the whitethorn hedge, between the garden and the court before the house, were the figures of several animals, castles, etc., formed in topiary, and that in the orchard there was the whitethorn figure of a wren's nest, big enough to hold a man. In the garden was a yew tree, which formed an arbor, measuring five yards square outside and three and a half inside, cut on the top with loop and crest, like the battlements of a town, adorn'd at each corner with a pinnacle, over which is wrought a canopy two yards in diameter, which is carried up gradually to a small pinnacle". Near the pale of the orchard was a "fine yew tree, cut up gradually from greater to lesser rounds, to the number of twenty".

The Victorians swept away the topiary, but a massive, old yew tree still stands in remaining garden.

The Victorians swept away the topiary, but a massive, old yew tree still stands in remaining garden.

"The garden walls and gate pillars date from the late seventeenth century, as do some of the outbuildings. Stone fleurs-de-lis, about two feet high, which formerly surmounted each of the gate piers, are said to have been the origin of the mark used by John Turner, the famous Staffordshire potter, whose father once lived at the Hall. During the nineteenth century restoration, the fleurs-de-lis were removed to the back garden, and replaced by two large stone balls. On the north-east side of the Hall is a large early eighteenth century red brick farm building with king-post roof and exposed first floor beams. The building seems to have been used as a malthouse in the last century. The sandstone gateposts and steps of the former path to the rear of Brewood Hall still stand in Vicarage Road, a short distance from Sandy Lane. The house of Hall Farm Close stand on the site of a large pond which was filled in about 1960. The pond may have marked the site of Brewood Hall quarry, said to have been very deep, which was full of water before 1869." [reference 3].

The main gate showing renovated gate piers with ball finials (prior to hanging of gates).

The main gate showing renovated gate piers with ball finials (prior to hanging of gates).

Period 1200 - 1786

Deer hunting was popular and King John is thought to have had a ‘Camera Regis’ (a temporary residence) on the site of Brewood Hall around 1204. The Fowke family became bailiffs of the Episcopal Manor of Brewood and Brewood Hall remained in this family for a number of generations. Brewood Hall was technically a 'Manor Peculiar' without extensive manorial lands. The Hall, gardens and orchards occupied only about six acres of land. "Brewood Hall is traditionally the site of King John's hunting lodge, and before the fourteenth century the semi-official residence of the bailiff of the Bishop's manor." [reference 3].

The pedigree of the Fowkes shows William Fowke living at Brewood Hall during the reign of Edward IV (1461-1483, with a brief interruption). During this period the ‘Leet’ (a Great Court) was held here.

Period 1786 - 1929

The Hall was owned by the Monckton's between 1786 and 1929 and the Turner family and others were tenants. In those times, landowners would often allow successive generations to be tenants, as long as the rent was paid.

Period 1929 - 1960

In 1929, Major R.P.F. Monckton sold Brewood Hall to Colonel C. O. Langley and it was the Langley family home for around 30 years. C.O. Langley was a partner in a solicitors practice (Fellows, Langley and Wright) in the town of Wolverhampton, about 8 miles from Brewood. He was also Borough Coroner and Stipendiary Magistrate in Wolverhampton. A son and daughter were brought up at Brewood Hall. Tragically, the son lost his life during the Second World War, whilst serving as a sub-mariner. His mother was unable to come to terms with the loss and became very reclusive. After the War, there were at least two part-time household staff. A housekeeper was accommodated in a modern cottage in Vicarage Road, about 5 minutes walk across the orchards which then lay at the rear of Brewood Hall. A gardner, handyman and chauffeur lived at Rambler Cottage, Sparrows End Lane, about two minutes walk from the Hall. Up until the 1960s, there was a substantial range of farm buildings next to Brewood Hall. Records indicate that Moncktons had an 'Estates Office' there in the 1950s, because they cite a fire at this office as the reason for not having the Title Deeds to a tract of disputed land in Coven.

Period 1960 - 1971

Following the death of his wife, C.O. Langley eventually decided to move to a smaller house in Wolverhampton. He disposed of Brewood Hall, with various outbuildings and the orchard, to Avion Properties in the 1960s. This company developed about five acres of the site for housing, resulting in the loss of some interesting buildings and all of the orchard, apart from one apple tree.

Until 1968, there was a large timber-framed barn with long straight braces to the lower panels. By the 1960s, it was in a very poor state of repair and, although there was an initiative to preserve the barn, it was not successful.

Large timber-framed barn at Brewood Hall, now demolished (Staffordshire Past Track).

Large timber-framed barn at Brewood Hall, now demolished (Staffordshire Past Track).

The photograph below is taken from 'The Turners of Lane End' [reference 5] and shows the setting of Brewood Hall as it was prior to the development in the 1960s. The Hall itself, on the left, is little changed in appearance today but the remaining buildings are either swept away or altered. The large Barn on the right of the drive remains, but the twin gabled building in the foreground was demolished, along with the part 2-storey/part 1-storey barn extending to the right. Tragically, the large timber-framed barn on the right was also demolished. The gable roof of another, long barn runs across the rear of the picture. Only the left end of this barn survives.

Brewood Hall circa 1960 (from 'The Turners of Lane End').

Brewood Hall circa 1960 (from 'The Turners of Lane End').

The photograph below, circa 1966 shows site as the changes were being made. The twin gabled building has been demolished, revealing the interior rear wall abutting the large barn. On the right, the part 2-storey and part 1-storey barn has gone. In the background, the long barn can been seen, but this was subsequently truncated.

Brewood Hall circa 1966 during partial demolition of the outbuildings (Staffordshire Past Track).

Brewood Hall circa 1966 during partial demolition of the outbuildings (Staffordshire Past Track).

This delightful hexagonal dovecote was also lost.

Dovecote at Brewood Hall, now demolished (Staffordshire Past Track).

Dovecote at Brewood Hall, now demolished (Staffordshire Past Track).

Brewood Hall, the 'Big Barn', the truncated barn (now dubbed the 'Little Barn' and the brick garden walls had all been designated as 'Listed Buildings, Grade II' and the developers were thereby prevented from carrying out further demolition. However, the property remained empty for some time and significant vandalism had occurred. I have no doubt that, before long, the buildings would have mysteriously 'gone on fire', had not the property been purchased.

Period 1971 - Present

The Hall and remaining Big and Small Barns, with around an acre of gardens, were acquired by J. C. Ford in 1971. We didn't get the original deeds on purchase as C.O. Langley's Abstract of Title was sufficient. The Hall was in part-vandalised condition, so the priority was to preserve the fabric and try to get at least part of the building habitable. My mother, a close family friend and I lived here and did the initial redecorations ourselves. In 1979 my partner joined us so there were four of us here. Over the next ten years my mother and family friend died and a difficult financial period allowed the house to become rather run-down but then my fortunes revived. I nursed my partner through a long illness until he died in 1999. I then set about conserving and redecorating the house with professional help and my hope is that this very special place can be kept in its present reasonable condition.

The Monckton family are still major landowners in the area. Stretton Hall is now the 'family seat' but they still own Horsebrook Hall and Somerford Hall.

The Giffard family have been in continuous occupation of Chillington Hall (but not the same building) since the de Giffards settled after the Norman Conquest.

Photograph References

For my pictures around Brewood, including pictures of some of the tombs in the churchyard, click here.

Pictures of the interior of the Parish Church and some of its memorials are here.

To give an idea of the extent of the village, there is also a series of pictures taken from the tower of the church. These are here. A further set of pictures was taken from the roof of Brewood Hall and these are here.

For Historic Pictures of Brewood Village, click here.

For Historic Pictures of Brewood Hall, click here.

Links

Brewood (Wikipedia).

Brewood: A Short History by David Horowitz).

Fooks and Fowke Family Trees.

GENUKO Brewood Parish Register - 1834.

Brewood Genealogical Records (Forebears).

Free British Ancestry.

Dustydocs.com (Australia).

Staffordshire, England Genealogy (UKIsearch.com).

Staffordshire Past Track.

References

[1] 'A History of the County of Stafford: Volume 5: East Cuttlestone hundred' (1959), Victoria County History

[2] 'Brewood' by Mary E. Wakefield, published in 1972 by Praill (Cannock) Limited.

[3] 'Brewood' by David Horovitz, (ISBN 1 85421 175 7).

[4] 'History and Antiquities of Staffordshire' by Stebbing-Shaw'.

[5] 'Master Potters of the Industrial Revolution - The Turners of Lane End' by Bevis Hillier.

In the post Waterloo Station, London I gave a brief introduction to this important London terminus. The later post Visiting former 'Southern' stations in London describes the adjacent station of Waterloo East and its footbridge connection to the main station.

Waterloo: the imposing 'Victory Arch' is the main entrance for foot passengers, rather spoilt in this 2010 picture by the temporary works in the foreground. Three years later, there were still works going on in this area!

Waterloo: the imposing 'Victory Arch' is the main entrance for foot passengers, rather spoilt in this 2010 picture by the temporary works in the foreground. Three years later, there were still works going on in this area!

The entrance shown above leads to the main concourse through a passage lined with four dignified panels forming a 'Roll of Honour' in memory of London and South Western Railway employees who were killed in World War I.

One of the four panels forming the WWI memorial.

One of the four panels forming the WWI memorial.

The World War II memorial is a more modest affair.

The WWII memorial.

The WWII memorial.

There is also a memorial commemorating the 50th anniversary of 'D-Day', placed by Railtrack South East in 1994.

The 'D-Day' memorial.

The 'D-Day' memorial.

My recent visit was on 13th September 2015 when I was involved in some alterations to the Tunnel Telephone system on the Waterloo and City Line. This time, I recorded the appearance of the 'Victory Arch' entrance from the concourse.

The main pedestrian entrance viewed from the concourse side.

The concourse side of the 'Victory Arch' is flanked by two imposing entrances leading to offices. The left hand entrance now leads to Network Rail offices but when I made a number of visits a few years ago it was the head office for 'Eurostar' and the words 'Eurostar House' can still be made out on the blue panel above the door.

Entrance to what is now Network Rail offices, incorporating a memorial to Herbert Walker. The bust above the door now sprouts plastic spikes to discourage pigeons. The words 'Eurostar House' can just be made out on the blue panel above the door.

Detail of the memorial to Herbert Walker incorporating a stone cameo.

The memorial reads:-

HERBERT ASHCOMBE WALKER K.C.B.

LONDON & SOUTH WESTERN RAILWAY

GENERAL MANAGER 1911-1923.

SOUTHERN RAILWAY

GENERAL MANAGER 1923-1937.

DIRECTOR 1937-1947.

THIS STATION, THE DEVELOPMENT

OF THE DOCKS AT SOUTHAMPTON

& THE ELECTRIFICATION OF THE

SOUTHERN RAILWAY,

TO WHICH HE GAVE HIS GENIUS &

LEADERSHIP, ARE HIS MEMORIAL

This tribute gives a hint of this towering figure, who led first the L&SWR and then the Southern Railway from 1911-1937. There's a Wikipedia article here. The memorial lists Waterloo, Southampton Docks and electrification as his major achievements.

Regarding the first of these achievements, Waterloo: The L&SWR didn't intend the line to end here. The destination for many of their commuters was the City of London and the railway's ambition was to extend the line eastwards. But the best they could achieve was to operate the one and a half mile long Waterloo and City underground electric railway from 1898. They later purchased the railway (which subsequently passed to the Southern Railway and then British Railways, transferring to London Underground in 2004). Unwilling to accept that the station would remain a terminus, the L&SWR allowed the site to develop in a rather haphazard way which resulted in, effectively, three stations side-by-side - North, Central and South, as shown in the 1888 plan below.

Plan of Waterloo station in 1888 (Flickr Commons by the British Library).

Click on image above for larger view.

By the end of the 19th century the inadequacies of Waterloo had made it a laughing stock. A light-hearted description of the trials of catching the train at Waterloo appeared in the book 'Three Men in a Boat (written by Jerome K. Jerome and published in 1889)and is included in my post on Jerome here. In 1899, finally accepting that Waterloo would remain a terminus, the L&SWR obtained permission for a total rebuilding of the station. J W Jacomb-Hood (L&SWR Chief Engineer) was responsible for the structure and planning. After his death in 1914 A W Szlumper continued the work. James Robb Scott (L&SWR Chief Architectural Assistant) produced the architectural designs. The rebuilding was finally completed in 1922 with the erection of 'The Victory Arch'. This arch is the only part of the station buildings which are Listed (Grade II in 2002). The English Heritage description reads:-

The Victory or Memorial Arch was built 1919-22. It was designed as the main foot entrance to the station at the head of an impressive flight of steps, most of which is within the building. it is in the form of a triumphal arch some three storeys and attic in height, on the butterfly plan; the main arch being flanked by side bays and with one bay canted wings. It Was joined to the existing building on the left by a three bay section with recessed centre and giant order, this is not repeated to the right. Balustraded parapet with attic hidden behind. Stonework with heavy rustication in the centre. Sculpture - Bronze plaques under the arch bear the names of 585 LSWR employees who lost their lives in WWI, but the chief features are two sculptural groups, one dedicated to Bellona and dated 1914 and the other, dated 1918, to Peace, under the names of the greatest fields of battle set around a glazed arch set with a clock in a sunburst, and surmounted on the roof by Britannia. Prominent on the concourse side of the arch is the name of the company. The sculptor was the other wise little known Charles Whiffen. The special significance of the monument within the post-First World War genre is that the LSWR staff themselves were, uniquely, consulted on its design. Pylons with iron lamps flank the staircase.

The rest of the station is not of special architectural or historic interest.

The dismissal of the rest of the station as without interest is an unkind opinion shared by Nikolaus Pevsner who, in his 'Buildings of England: London' called the steelwork “sadly timid” and the facade “spoiled by a hopeless position”. Stuart Durant on The Victorian Web is more even in his judgement, writing "Waterloo, despite its architectural failings — in particular its vainglorious attempt at monumentality — is a pleasant and efficient station. For all the lack of bravura of the scheme, the glazed roofs of Jacomb-Hood and Szlumper give Waterloo some of the best natural lighting of any station." Personally, I consider Waterloo to be one of the more delightful survivals of London's railway terminals together with the rather more heavily modified candidates of King's Cross and St. Pancras. I certainly agree regarding the success of the glazed roofing.

Station Approach looking south-west showing the curtain wall adjacent to platform 1 (left) and the east end of the main station building (right).

Station Approach looking south-west showing the curtain wall adjacent to platform 1 (left) and the east end of the main station building (right).

The curtain wall adjacent to platform 1.

The curtain wall adjacent to platform 1.

I found one further war memorial: a simple tribute to the fourteen men of Nine Elms locomotive depot who "died by enemy action 1939-1945". I suspect that this memorial was originally located within the buildings of the Motive Power Depot and was re-sited at Waterloo when the Depot was abolished. It is now positioned on the wall adjacent to Starbuck's.

Nine Elms Motive Power memorial.

Nine Elms Motive Power memorial.

Before the rebuilding of the station, there was one little-used through line at the Central station which crossed Waterloo Road on a bridge and connected with the SE&CR line at what is now Waterloo East. The arrangement can be seen in the 1888 plan below.

Waterloo Station, viewed from Waterloo Road. The overbridge originally carried a single line to Waterloo East and a footpath and now appears to be in use for cable drum storage. The more modern pedestrian bridge at a higher level now links Waterloo and Waterloo East.

Waterloo Station, viewed from Waterloo Road. The overbridge originally carried a single line to Waterloo East and a footpath and now appears to be in use for cable drum storage. The more modern pedestrian bridge at a higher level now links Waterloo and Waterloo East.

Sandell Street viewed from Waterloo Road. The blue bridge presumably carried the former connecting line to Waterloo East. The roof over the high level footbridge changes to the inelegant form shown, once clear of Waterloo Road!

Sandell Street viewed from Waterloo Road. The blue bridge presumably carried the former connecting line to Waterloo East. The roof over the high level footbridge changes to the inelegant form shown, once clear of Waterloo Road!

There's a Wikipedia article on Waterloo Station here.

Network Rail are planning significant further expenditure to bring the rest of the International station back into use and extend platforms 1 to 4. The rather nice aerial view below accompanies their write-up here

Waterloo Station from the air (Photo: Network Rail).

Waterloo Station from the air (Photo: Network Rail).

Click on image above for larger view.

My pictures

London: Waterloo Station

TURNTABLE ORIGINS

The turntable (or 'turnplate') appeared early in the development of railways, initially as a means of routing single wagons from one line to another at coal mines and similar installations and often narrow-gauge.

A cast narrow-gauge wagon turntable preserved at Black Country Living Museum (without the approach tracks).

A cast narrow-gauge wagon turntable preserved at Black Country Living Museum (without the approach tracks).

When the first steam railways were built, the size of turntables was increased to allow shunting of passenger coaches and turning of the small locomotives then in use. No passenger station lacked a battery of turntables to assist in marshalling each train. The 'Roundhouse' design of locomotive shed using a turntable to access a number of radiating stabling roads was used as early as 1846 by the London and Birmingham Railway (there's a very brief description of that line here). The building of the roundhouse locomotive shed built at Camden survives as a Grade II* listed building and is now used as a performing arts and concert centre called Roundhouse. There are brief details of the building on Jack Whitehead's Local History website here.

Camden, showing the London and Birmingham locomotive roundhouse of 1846 (now the Roundhouse Theatre).

Camden, showing the London and Birmingham locomotive roundhouse of 1846 (now the Roundhouse Theatre).

Eventually, small turntables became confined to goods yards and canal interchanges. They were often provided in large numbers, sometimes associated with capstans so that haulage ropes could be arranged allowing horses to move the wagons. The sketch map below shows the sidings and wagon turntables at the canal interchange basins at Bloomfield in the West Midland area of England in the early years of the 20th century.

A larger version of this sketch can be found here.

A larger version of this sketch can be found here.

There's a brief write-up about the canals and sidings at Bloomfield in the post Rail and Canal at Bloomfield.

The picture below shows a typical standard-gauge wagon turntable, this one preserved in Birkenhead Docks.

Birkenhead: Wagon Turntable adjacent to Duke Street Lifting Bridge.

Birkenhead: Wagon Turntable adjacent to Duke Street Lifting Bridge.

There's a write-up of my exploration of Birkenhead's Docks in the post Birkenhead and New Brighton by train (Part 2).

LOCOMOTIVE TURNTABLES

Developments in locomotive design produced larger engines which required longer turntables. In Britain, turntables up to 70 feet in length were made. There's a Wikipedia article here.

The following description is based on an article published in The Locomotive Magazine and Railway Carriage and Wagon Review, dated 15th February 1937. This article, in turn, was 'a brief abstract of the main points mentioned' in a paper on Locomotive Turntables read to a meeting of the Institution of Mechanical Engineers on 27th January 1937 by Associate Member Mr. J. H. A. Wilkins.

Modern locomotive turntables conform to one of three types:-

1. The cantilever, or centre balanced type: either 'through' or 'deck' pattern.

2. Articulated or centre hinged type.

3. Continuous girder type supported at three points (Mundt type).

Of more than 900 turntables in use in 1936, most were centre-balanced type with only around 20 ar and 20 of the continuous girder (Mundt) pattern. In the U.K, the largest turntable in use is 70 ft. diameter.

1. Cantilever or centre balanced type supported on the centre pivot

The turntable is balanced in the centre, the main girders acting as cantilevers. Two strong wrought iron or steel plate main girders are braced together by stretchers and securely attached to a middle framework which rests on and revolves around a centre pin fixed to a solid foundation. Large carrying wheels which travel on a rail laid round the circumference of the pit are attached to both ends of the main girders.

In use, the locomotive to be turned is centred or 'set' so that the majority of the weight is taken by the centre pivot, and a small force applied to the ends of the main girders is able to turn the table. To assist in achieving the necessary balance, the length of the table should be several feet longer than the wheel base of the locomotive.

During erection, the large carrying wheels are given a slight clearance from the circumferential rail and carry that part of the weight not supported by the centre pivot.

If a locomotive is perfectly balanced, all the weight is carried by the centre pivot, otherwise part of the weight is supported by the large carrying wheels at one end of the turntable.

The centre pivot comprises a cap or yoke cast in steel which supports the main girders by large suspension bolts. The cap rests on a pivot bearing, typically made of 'UBAS' case hardening steel supporting a bronze, gun-metal, or steel cup ('UBAS' was a trade mark used by W. T. Flather who manufactured special steels). If an anti-friction thrust bearing is incorporated, this is enclosed in a steel housing resting on, and positioned on, the stump or centre pivot. The centre pivot takes the full load of the turntable and locomotive when in use and is usually cast iron, secured by rag bolts or similar to a solid, normally concrete, foundation.

Because of the clearance given to the large carrying wheels, 'blocking pads' are provided to take the weight of the locomotive when running on or off the turntable. In some cases the hand lever for operating these blocking pads also operates the locking bolts for holding the table in position opposite the various roads radiating from the pit. In its horizontal position this lever is sometimes used for turning the table manually.

In some designs, levers to operate the blocking pads and locking bolts are replaced by hand wheels at each end of a shaft running the whole length of the turntable girder, so that turning the hand wheel at either end operates the blocking pads and locking bolts at both ends. The locking bolts also serve as blocking pads in some designs, engaging in a cast iron locking rest fixed in the pit wall where each track radiates.

The centre-balanced main girder may be of 'deck' (under girder) or 'through' (over girder) design.

In the 'deck' type, the rails are laid upon the top of the main girders, simplifiying construction but requiring a deep pit to accommodate the height of the main girders.

In the 'through' type, the rails are laid between the main girders, carried on cross members. This allows the use of a shallower pit. The G.W.R. normally use the 'through' type in outside locations (a 65 ft. turntable on the GWR at Oswestry was cited as an example) where a notice visible to the engineman reads "All engines must stop before going on to the turntable." so as to avoid shock as the locomotive runs on to the table, due to the clearance on the large carrying wheels). The 'through' type, although possessing the advantage of requiring only a shallow pit, weighs considerably more itself due to the heavier construction and greater width, and costs more than the 'deck' type.

2. Articulated or centre hinged type supported at three points

This design is credited to a Chief Inspector of Locomotives on a German railway called Herr Klensch who sold his patent to Messrs. Julius Vogele in Mannheim. They, in turn, granted licences to manufacturers in Germany and elsewhere.

The articulated turntable is divided into two beams, supporting the load over the centre pivot and the large carrying wheels at each end of the turntable which are always in contact with the circumferential rail. The large carrying wheels take at least half of the load on the turntable and it can be driven from either end.

Because the large carrying wheels remain in contact with the rail, the ends of the table are not violently depressed when a locomotive runs on to it, reducing the shocks which occur with the cantilever or centre balanced type descried above in which, when correctly balanced, the large carrying wheels remain clear of the rail.

One advantage of dividing the main girders in this design is that girder height can be reduced, allowing the use of a shallower pit.

The articulated or centre hinged design found favour in the U.S.A. where lattice girders were often used. Elsewhere riveted plate girders or rolled girders were generally used.

With an evenly-distributed load, the thrust bearing of the centre support carries half the total load the balance being carried by the large carrying wheels. The centre joint must be sufficiently robust to prevent slackness occurring which allows the large carrying wheels to skew, increasing the resistance to turning when the table is driven from one end only. A number of designs of centre joint using flexible hinge plates and laminated spring joints were evolved.

3. Continuous girder type supported at three points (Mundt type)

Mundt was an engineer with the Dutch State Railways and his improvement of the centre-hinged type eliminated the centre hinge by allowing a continuous girder to deform under load. The continuous girders are not of uniform section throughout, but are reinforced from each end to a certain distance short of the centre pivot. This allows of sufficient flexibility to prevent the rising of the unloaded end of the table with a unbalanced load (for instance, a short locomotive at one end).

The turntable may be driven from either end and no balancing is required - the locomotive can be turned immediately the last wheels of the engine or tender run on to it a no blocking up of the table is required.

Again, the design allows the use of reduced girder height, shallower pits and a centre support required to carry only half the total load.

A variation of the Mundt pattern, widely used in the U.S.A., uses unreinforced girders where bending throughout the length is provided. To ensure proper adhesion, these types are normally driven at both ends by electric motors.

TESTING LOCOMOTIVE TURNTABLES

Testing of locomotive turntables is usually carried out at the manufacturer's own works using a temporary track. The table is manufactured in sections (as in steel bridge construction) assembled with bolts in place of rivets to allow the structure to be taken apart for despatch to the customer. The test load is usually made up iron castings of known weight which are built up to the total weight required. The test load is stipulated on the contract, and is usually 25% above the weight of the heaviest locomotive which the table is designed to carry. The individual Loads are arranged to represent the axle loading of the heaviest class of locomotive which will use the turntable. Deflection tests of the main girders are made at the ends and between the ends and the centre. After the test load is removed, observations are made for any permanent set which may have taken place. The locking gear is carefully tested. This testing is usually witnessed by representatives of the customer.

When the turntable has been re-erected on its permanent site, it is then tested again by running the heaviest locomotive which will use the table on to it, and any final adjustments are made.

TURNTABLE OPERATION

Early forms of turntable (before the use of anti-friction pivot bearings and carrying wheels became general) were operated by a winch driving gearing either fixed to the end carrier or directly to a toothed ring forming part of the wheel path. In some cases, the winch was driven by a small steam engine or hydraulic power.

Modern turntables may be operated:-

1. Manually

2. Electric motor

3. Vacuum motor

4. Compressed air motor.

1. Manual operation

The turntable is operated by a two-handled winch mounted at one end of the turntable deck. The crew of the engine to be turned provide the turning power. Extending beams are sometimes fitted to allow extra people to assist in pushing the turntable deck. In the 1930s, the majority of turntables in the UK were manually operated.

2. Electric operation

World-wide, this is the most common method of operation, particularly on larger turntables and almost universal in the U.S.A. At busy locations, the time saved by electric operation is significant. A control cabin is often mounted on the turntable deck and a man stationed in this cabin allows the engine crew to remain on the footplate during turning. In the U.K., both the GWR and LMS installed electrically-operated turntables but in 1935 there were under 30 in this country, compared with over 900 in the U.S.A. divided over 58 railway companies.

The electric motor is usually a totally-enclosed traction type. A tramway type controller with magnetic blowout, electric brake, current reverser and associated resistors is provided, often mounted within the control cabin. The controller usually has one handle for forward running and braking and another for reversing. A foot brake is provided working on a pulley keyed to the main or intermediate driving shaft.

Current collection to the rotating deck is either by electrical contacts in the pit or via an overhead cable to a gantry mounted at the centre of the deck provided with electrical slip-rings.

3. Vacuum operation

This method of driving is patented and manufactured by Messrs. Cowans, Sheldon & Co. Ltd. The apparatus consists briefly of a central valve chest mounting two double acting oscillating cylinders, each 4in. diameter by 6in. stroke, running at 350 rpm. and driving a crank shaft on which a pinion meshes with gearing which drives the large carrying wheels. All that is necessary when the locomotive is driven on to the table is for the vacuum brake pipe, either at the front or rear of the locomotive, to be connected to the flexible coupling of the tractor. The vacuum ejector on the engine is then opened and one of the engine men works the controls to operate the vacuum motor. There's a brief description of the 'Oscillating Cylinder Engine' here.

4. Compressed air operation

In the steam locomotive era, most British railway administrations used vacuum brakes but overseas air brakes were common. To cater for this market, the Cowans, Sheldon vacuum motor was adaptable to operate from the compressed air supply on an air braked locomotive.

BRITISH TURNTABLE MANUFACTURERS

There were two principal British manufacturers:-

Cowans, Sheldon and Company of Carlisle, perhaps better known as crane makers.

Ransomes and Rapier Limited of Norwich, also crane and machinery manufacturers.

Cowans, Sheldon and Company

A drawing of a Cowans, Shelton turntable in the collections of Tullie House Museum and Art Gallery, Carlisle. Click on the image for a larger view.

See also Grace's Guide.

Ransomes and Rapier Limited

A 1921 advert for 'Traversers and Turntables' (Grace's Guide).

See also Grace's Guide

Brief details of Ransomes and Rapier documents held by Ipswich Transport Museum on behalf of the National Archives are here.

EXAMPLES OF TURNTABLES IN USE

Birmingham Railway Museum, Tyseley

Tyseley retains its turntable with radiating stabling roads from its former life as a Briitish Rail Motive Power Depot, although the building which originally covered both turntable and stabling roads had gone (along with a second building, turntable and stabling roads). For years, we operated this turntable by hand, although it had originally been electrically operated. Eventually, electric operation was restored. The turntable, a 'Mundt' type, had been supplied by Ransomes and Rapier Ltd.

and the worksplate was marked:-

Rapier

146 tons Mundt Turntable

Made For B.R. Contract No.1114-M&E

Ransomes and Rapier Ltd.

OR.G.J.4985 Ipswich England 1957.

There's a picture (by Stuart Axe) of this worksplate here.

Peak Rail, Rowsley

The original turntable here had been removed and the pit filled in. In a major restoration, the pit was dug out, re-bricked and a 60-foot turntable originally supplied to Mold Junction M.P.D. was installed. This is a Cowans and Sheldon turntable, operated by the original 2-cylinder vacuum motor.

The 60-foot turntable at Rowsley during installation. This Cowans Sheldon Co. Ltd turntable (O/N 6181 5-Mar-1937) was originally supplied to Mold Junction M.P.D.

The 60-foot turntable at Rowsley during installation. This Cowans Sheldon Co. Ltd turntable (O/N 6181 5-Mar-1937) was originally supplied to Mold Junction M.P.D.

There's a little more information on the Peak Rail website here.

The re-commissioned turntable at Peak Rail was inaugurated by Pete Waterman on 1st May 2010, as described here.

With Pete Waterman at the regulator, 8624 slowly reverses off the turntable (Photo: Sheila Rayson).

With Pete Waterman at the regulator, 8624 slowly reverses off the turntable (Photo: Sheila Rayson).

There is a collection of my pictures showing the Rowsley turntable in detail here.

Wolsztyn, Poland

'Piekna Helena' on the turntable at Wolsztyn.

'Piekna Helena' on the turntable at Wolsztyn.

There's a brief description of my visit here and my pictures are here.

Kolomia, Ukraine

Su 251-86 on the turntable at Kolomiya.

Su 251-86 on the turntable at Kolomiya.

There's an introduction to my trip to Ukraine, with links to other posts and pictures here.

Kiev, Ukraine

A large turntable in Kiev serving an 8-stall roundhouse and the works. Note the overhead catenary.

A large turntable in Kiev serving an 8-stall roundhouse and the works. Note the overhead catenary.

There's an introduction to my trip to Ukraine, with links to other posts and pictures here.

Mahlwagon, Yangon, Myanmar

Mahlwagon Diesel Shed Turntable: 120 ton capacity metre gauge Mundt turntable built by Ransomes and Rapier in 1946.

Mahlwagon Diesel Shed Turntable: 120 ton capacity metre gauge Mundt turntable built by Ransomes and Rapier in 1946.

There's a description of my visit to Mahlwagon Diesel Locomotive Shed here and my pictures showing the turntable at Mahlwagon are here.

A Model Turntable

A model turntable in 4mm/foot scale.

A model turntable in 4mm/foot scale.

There are more details of this model railway here.

There's an article on Wikipedia about railway turntables here.

[Link to 'The Oscillating Cylinder Engine' added 25-Oct-2015]

In the post 'Planet' at MOSI - The First 21 Years, I celebrated the 21st Birthday of the 'Planet' replica in October 2013.

When I was driving the 'Planet' replica, people sometimes asked if it was different from driving 'modern' steam locomotives. The answer is "not very, apart from the the fact she's a 'single wheeler', has a rather special braking system and an unusual method of reversing" ('Planet', like its immediate predecessor 'Rocket' has Slip Eccentric reversing). The basic principles of the steam locomotive haven't changed very much since the early days, although the appearance of the 'Planet' replica is very different from modern steam locomotives.

The 'Planet' replica being prepared for service with MOSI volunteer

Bev on the right.

I've already written about driving another early locomotive design in the post Driving 'Lion'. 'Lion' was built just eight years after the original 'Planet' and so there are many similarities, although 'Lion' incorporates Gab motion for reversing.

Adhesion

'Planet' has just one pair of driving wheels, which share the total weight of the locomotive with the leading pair of carrying wheels. Using Whyte's Notation, the arrangement is said to be a '2-2-0'. The total weight on the driving wheels is the 'adhesive weight'. With a single driving axle, not all of the locomotive weight can be adhesive. In the case of the original 'Planet' there was about 5 tons on the driving wheels, with about 3 tons on the carrying wheels. When the driver wants to get the train in motion, steam is used to generate sufficient torque at the driving wheels to move the load. But, if the torque applied to the driven wheels exceeds a critical value (related to the coefficient of friction between the wheels and the rails), the driving wheels slip on the rails and the train does not move.

This was more of a problem with goods trains, which tended to be heavier, so it was desirable to make all the locomotive weight adhesive to reduce the risk of slipping. On goods engines (then called 'luggage engines') the torque generated on the two driving wheels was shared with a similar pair of wheels linked to the driving wheels with coupling rods, giving a wheel arrangement of '0-4-0'. As the size and weight of locomotives increased, further coupled wheels were often used, although 'single-wheelers' weren't eliminated for some years as they could be free-running and, with large driving wheels, fast.

Because the 'Planet' replica only has one pair of driving wheels, it can be 'light on its feet' and prone to slipping so the driver has to take care when starting not to open the regulator too far.

Braking

In the early days of steam locomotives, effort was concentrated on making machines powerful enough to pull a useful load and braking technology was rather neglected. On both the original 'Planet' and the replica, there are two hand brakes, one on each side of the tender, and these are applied by 'screwing down' the handles which project from the top of the tender. Wooden brake blocks are provided which rub against the tyres of the tender wheels to provide braking. On the original 'Planet' that was it! This arrangement wasn't terribly effective in 1830 (severe braking could set the brake blocks on fire!) and, in the replica, the hand brakes are normally used only as a 'parking brake'.

Left side of replica tender showing the cast decorated panel and wooden brake blocks which are pulled against the tyres of the tender wheels by the screw handbrake to provide braking. Brake discs and calipers for the modern air brakes are visible between the wheel spokes.

Left side of replica tender showing the cast decorated panel and wooden brake blocks which are pulled against the tyres of the tender wheels by the screw handbrake to provide braking. Brake discs and calipers for the modern air brakes are visible between the wheel spokes.

To be acceptable for hauling passenger trains today, the 'Planet' replica also has an Air Brake system. This operates a disc brake on the leading axle of the locomotive, disc brakes on both tender axles and the train brakes. The regulator should always be closed before attempting to brake. I talk a bit about braking and the use of the automatic Vacuum Brake here. Air Brakes form another type of automatic braking (which I've not, to date, described). With the withdrawal of steam traction in the U.K., British Railways started to change over from vacuum braking to air braking and the 'Planet' replica has a version of what became the standard British Railways Two-Pipe Air Braking system.

Converting steam into rotary motion

This part of the locomotive has changed little since the early days. The 'Planet' had two horizontal cylinders at the front between the frames. When the regulator is at least partly open, steam flows through the main steam pipe to feed the two cylinders. The principle is simple - the steam under pressure is used to push a piston to the far end of a steam-tight cylinder. The picture below shows a deliberately 'sectioned' cylinder making the construction clearer. The piston is attached to a Piston Rod which sticks out of one end of the cylinder (through a steam-tight piston gland) and it's the motion of the piston rod which allows the cylinder to do useful work.

'Sectioned' cylinder on Beyer Peacock locomotive 'Pender' on display at MOSI. The piston is shown in its rearmost position in the cylinder and the Piston Rod extends to the left.

'Sectioned' cylinder on Beyer Peacock locomotive 'Pender' on display at MOSI. The piston is shown in its rearmost position in the cylinder and the Piston Rod extends to the left.

As the piston approaches the end of the cylinder, it's necessary to cut off the supply of steam and divert the steam to the other end of the cylinder so as to push the piston back again. This requires a valve in between the steam supply and the cylinder called (logically enough) the Steam Valve. The opening and closing of this valve must be synchronised with the movement of the piston. The two pictures below of the 'Planet' replica give an idea this was engineered in 1830, using complicated iron castings which were at the limit of what was technically possible.

The first picture below is taken inside the smokebox of the 'Planet' replica looking down onto the top of the left hand cylinder with the steam chest removed from the threaded mounting studs so as to show the flat port face area with two rectangular steam ports (connected to each end of the cylinder) and the larger rectangular exhaust port (connected through a passage to the blast pipe).

Top view of cylinder showing the cylinder ports (2 steam, 1 exhaust).

The second picture shows the underside of the steam chest which has been removed in the first picture. The steam chest is complete with the cast rectangular steam valve attached to the valve rod which sticks out of one end of the steam chest (through a steam-tight valve gland). The flat face of the valve bears slides to and fro against the flat port face so this type of valve is called a Slide Valve.

Steam chest complete with slide valve and valve rod.

Steam chest complete with slide valve and valve rod.

The reciprocating motion of the two piston rods is converted to rotary motion of the driving axle by connecting rods linking the end of the pistons which pull and push a double-crank driving axle, as shown in the picture below. Practical locomotives have at least two cylinders and, on a 2-cylinder design, the cranks are set 90 degrees apart so that both cylinders cannot be on dead centre. This means that a locomotive can always be started (using the effort from at least one cylinder), whatever the position of the cranks.

More than a century after the building of the original 'Planet', similar arrangements remained in use. An increasingly common variation was to move the cylinders outside the frames where the connecting rods drove onto crankpins fitted to the driving wheels, but both inside cylinder and outside cylinder designs lasted until the end of steam. Some designs had additional cylinders and a locomotive might have both inside and outside cylinders. As locomotives became larger, slide valves were replaced by balanced slide valves and then piston valves. A variety of other valves (poppet, sleeve) were tried but piston valves emerged as the most practical form of valve. A few attempts were made using quite different techniques, like steam turbines, but double-acting reciprocating cylinder designs remained virtually unchallenged.

Valve Gear

As remarked above, the opening and closing of the steam valve to admit steam from the boiler to either end of the cylinder must be synchronised with the movement of the piston. Since the piston is used to turn the driving axle, if the motion of the steam valve is derived from the turning of the driving axle, the necessary synchronisation is obtained. The motion of the steam valve is derived from the rotation of the driving axle on this design by a special eccentric. A simple eccentric is a type of crank with a small 'throw' - see Wikipedia here. A simple eccentric is fixed to the axle which turns it so as to produce the correct valve events to rotate the driving axle in one direction.

But a locomotive must be able to move in both directions and this was achieved in 'Planet' and other early locomotives by the use of a Slip Eccentric for each cylinder mounted in the middle of the crank axle, as shown in the picture below. A Slip Eccentric is an eccentric which can engage with the crankshaft in two positions where one provides the correct movements of the eccentric rod and the valve rod for clockwise rotation of the driving axle whilst the other position produces anticlockwise rotation of the driving axle. This is achieved by providing lugs or 'dogs' which can engage with one of two mating recesses or pits. A transverse shaft operated from a foot pedal on the footplate is used slide each eccentric across the axle so as to disengage one lug and allow the other lug to engage when the axle has turned so as to bring the other recess in line.

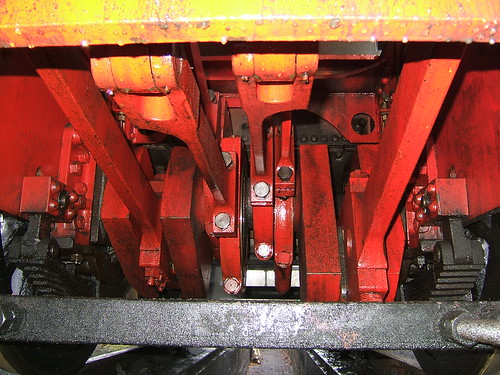

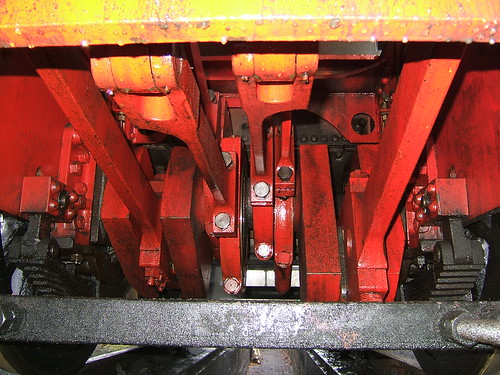

"Planet's" driving axle and eccentrics viewed from below. L-R: RH driving wheel, intermediate axlebox, RH crank driven by (black) connecting rod, inside axlebox, RH eccentric and rod, LH eccentric and rod, inside axlebox, LH crank driven by (black) connecting rod.

"Planet's" driving axle and eccentrics viewed from below. L-R: RH driving wheel, intermediate axlebox, RH crank driven by (black) connecting rod, inside axlebox, RH eccentric and rod, LH eccentric and rod, inside axlebox, LH crank driven by (black) connecting rod.

Click here for a larger view

So, reversing the locomotive involves disengaging one lug in the slip eccentrics and turning the driving axle until the other lug engages. Achieving this probably provides the biggest challenge to the driver. There are two ways of achieving this changeover:-

1. Turn the driving axle by controlling the valves manually.

2. Perform a 'flying reverse'.

Reversing by controlling the valves manually involves operating the foot pedal to the other position, disengaging both valves from the eccentric rods (by operating the two small valve locking levers mounted on top of the left and right footplate railing) and operating the valves appropriately by hand (using the two curved levers mounted on the boiler backhead facing the driver) so as to move the locomotive. When the eccentrics have re-engaged, the two small valve locking levers are used to re-connect the eccentric rods with the valves, allowing the locomotive to be driven normally.

The 'flying reverse' is potentially simpler but requires careful judgment. This can be used if the locomotive is already in motion in one direction and requires to stop and then re-start in the opposite direction. The driver closes the regulator and uses the brakes so as to stop in the correct position. Before actually stopping, the foot pedal is operated to the other position. If judged correctly, the slip eccentrics will engage for the opposite direction before the locomotive comes to a stand. The 'flying reverse' can also be used if the locomotive is stationary but on a sufficient gradient so that it will roll when the brakes are released.

The view below of the footplate of the 'Planet' replica, shows the location of the controls used by the driver when reversing.

The 'Planet' replica in the Power Hall at MOSI. L-R: Steam chest pressure gauge, valve locking lever (on top of railing), two long curved levers (for manual operation of valves), foot pedal (for reversing), water gauge, regulator, water gauge, blower valve with injector steam cock below, boiler pressure gauge, valve locking lever (on top of railing).

Click here for a larger view

The two valve locking levers and the two long curved levers for the manual operation of the valves connect to the front of the locomotive via a series of rods. The picture below shows the two rocking shafts (top of picture) which operate the valve spindles controlling the valves in the steam chests described above. When the small valve locking levers are engaged, each rocking shaft is driven by the associated eccentric rod. To allow manual operation of the valves, the small valve locking levers disengage the eccentric rods from the rocking shafts by two shafts operating lifting links (near the bottom of the picture, painted green) which disengage each eccentric rod from its valve spindle.

Looking at the front of the cylinders from underneath the locomotive showing the method of disengaging the valves from the eccentric rods. The cylinder front covers are dummy, made to the diameter of the original 'Planet'. The replica 'Planet' has smaller cylinders because of the increased working pressure (100 p.s.i. compared with 50 p.s.i. in the original).

Looking at the front of the cylinders from underneath the locomotive showing the method of disengaging the valves from the eccentric rods. The cylinder front covers are dummy, made to the diameter of the original 'Planet'. The replica 'Planet' has smaller cylinders because of the increased working pressure (100 p.s.i. compared with 50 p.s.i. in the original).

Click here for a larger view

Development of Valve Gear

Slip eccentric reversing of locomotives did not survive. By providing four fixed eccentrics and eccentric rods, rather than two, the correct valve movements for both directions of movements on two cylinders could be provided. Initially, a mechanism connected to a simple reversing lever on the footplate connected two of the four eccentric rods to the valve spindles. For instance, 'Lion' of 1838 features Gab motion.

But, by 1842, Stephenson's link motion appeared in the U.K. offering not only reversing but variable cut-off allowing steam to be used expansively for greater efficiency. This became the predominant valve gear in the U.K. for many years. Don Ashton's authoritative review of Stephenson Link Motion can be found here,

For comparison with the picture above showing "Planet's" driving axle and eccentrics, the picture below shows "Sapper's" driving axle and eccentrics. "Sapper" is an 0-6-0 'Austerity' tank built more than a century after the original "Planet". Stephenson Link Motion had replaced slip eccentric reversing but otherwise the layout is similar.

"Sapper's" driving axle and eccentrics viewed from below. L-R: RH axlebox and underhung laminated spring, RH crank driven by (red) connecting rod, RH fore eccentric and rod, RH back eccentric and rod, LH back eccentric and rod, LH fore eccentric and rod, LH crank driven by (red) connecting rod, LH axlebox and underhung laminated spring.

"Sapper's" driving axle and eccentrics viewed from below. L-R: RH axlebox and underhung laminated spring, RH crank driven by (red) connecting rod, RH fore eccentric and rod, RH back eccentric and rod, LH back eccentric and rod, LH fore eccentric and rod, LH crank driven by (red) connecting rod, LH axlebox and underhung laminated spring.

Click here for a larger view

Design issues

In general, materials and manufacturing techniques now are far superior to anything available in 1830. Steel was not available then - wrought iron was the best material but quality was very variable and only limited size sheets were available which required joining by riveting. Cast iron in the complex forms required for cylinders and valve chests was pushing at the limits of the technology available at the time.

The 'Planet' replica incorporates a number of features which were not possible in 1830 (for instance, air brakes, blower, injector, whistle, water gauges, pressure gauges) but that discussion I'll defer to a later article.

Related posts on this website

Early Locomotive Design.

The Planet Replica.

If your interest is broader than just the 'Planet' replica, there's a series of articles describing working on preserved railways and driving various steam locomotives. Most of these articles can be found here

My Pictures of the 'Planet' replica

'Planet'.

The Doctors' Surgery in Sandy Lane, pictured in 2008.

The Doctors' Surgery in Sandy Lane, pictured in 2008.