skip to main |

skip to sidebar

On Friday, 5th November 2021, I made a brief visit to Stockport for a business meeting, travelling between Wolverhampton and Stockport using the 'CrossCountry' services in both directions via Stoke-upon-Trent. As the 2021 United Nations Climate Change Conference, also known as COP26, was taking place in Glasgow to agree how our world could be saved, bizarrely both my journeys entirely 'under the wires' featured Class 221 diesel multiple unit haulage because of non-electrified mileage at the beginning (northbound service from Reading) or end (southbound service to Southampton) of the route.

Timetables and operations have been altered because of the Covid Pandemic and I was quite surprised to see how busy services were, operated in both directions by two 4-car Class 221 coupled together

For many years I was a volunteer at Manchester's Museum of Science and Industry (there are a number of posts here), so I was a frequent traveller both by road or by train to Manchester. By train, I used the routes through either Stoke-upon-Trent or Crewe which normally called at Stockport. But, my most recent train journey to or through Stockport was some time ago so I welcomed a chance to see what had changed. Not much, it appeared. Since Avanti West Coast took over the 'Pendolino' services between London and Manchester from Virgin, they have also taken over management of Stockport station but, of course, they host the services of a number of other Train Operating Companies, including 'CrossCountry'.

I won't repeat my distaste for the 'new' (and still incomplete) Wolverhampton station. Fortunately, I didn't have long to wait on draughty platform 2 for my train. The rather modest accommodation on island platform 2/3 with simple, flat canopies remains as constructed by British Railways, albeit with some internal modernisation.

Wolverhampton Station: view from second overbridge looking towards Birmingham showing left platform 2, right platform 1. There was formerly a Middle Siding between the two tracks for which the overhead catenary remains (Blackpool by Electric Train)

I found my reserved seat (a couple who'd commandeered my seat sheepishly apologised and immediately moved elsewhere). The journey to Stockport was incident-free and on time but I'm still not a great fan of the Bombardier design. The Class 221 has 'tilting technology' to allow higher maximum speed but I understand it was taken out of use years ago to limit maintenance costs. Allowance for the six degrees of tilt either way results in the body being narrower at roof level that floor level, giving a distinctly 'narrow-bodied' feel to the passenger compartment.

Each coach has a Cummins QSK19 underfloor-mounted 6-cylinder, 6-litre turbo diesel driving an electric generator to power one traction motor on each bogie. To generate 750 h.p., the engine is run at up to 1800 r.p.m. which I find generates uncomfortable noise and vibration. Dellner autocouplers are provided.

'Cross Country' Voyager in 2010: detail of Dellner autocoupler with twin horns below.

Approaching Stockport, the appearance of the London and North Western designed signal box at Edgeley Junction Number 1 always makes me smile. In general, the route from Euston to Manchester is now commanded by a chain of modern Railway Operating Centres and Signalling Control Centres but, through Stockport, the main line is still controlled by a group of venerable signal box structures, even if now bereft of their original mechanical signalling equipment. These are Edgeley Junction No. 1 (where the line from Buxton converges), Edgeley Junction No. 2 (where the line from Chester converges), Stockport No. 1 (south end of station) and Stockport No. 2 (north end of station). Nearer Manchester, Heaton Norris Junction, a more modern brick structure retaining a mechanical frame survived for some years but has now been abolished.

Edgeley Junction No. 1 signal box.

Stockport station is a strange amalgam of two very-recognisable London and North Western station buildings on island platforms 1/2 and 3/4 (internally modernised) which lead via a subway to a modern booking hall on the town side which gives access to a 'new' platform.

The 'new' platform is numbered '0' and unusual platform numbering, including the use of '0', intrigues me. There are a couple of posts here and here on the topic.

Stockport: View from platform 0 looking towards Crewe in 2013 showing two '0' platform signs (the smaller '4' sign is the stop marker for 4-coach trains).

Stockport: View from platform 3 in 2013 showing the LNWR station building on platform 1/2.

Stockport: View from platform 0 looking towards Crewe in 2013 showing the LNWR station building on platform 1/2.

Stockport: View from platform 2 looking towards Manchester in 2013 showing the LNWR station building on platform 3/4.

Stockport: Modern station building on Up side in 2013.

After my meeting, I returned to Stockport station with less than ten minutes to wait for a Southampton-bound 'Cross Country' which would deliver me back to Wolverhampton in around one hour. Being a Friday and late afternoon, the train was very full but I managed to find an unused seat so that wasn't too bad at all.

Related posts in this blog

The Buxton Branch.

Zen and the Art of Platform Numbering.

Platform Numbering Revisited.

My pictures

Pictures taken on earlier travels in Stockport area are here:-

Manchester Area Rail

I was rostered as DMU (Diesel Multiple Unit) driver at the Battlefield Line on Saturday, 2nd October 2021.

The 'set' comprised the Driving Motor car at the north end coupled to the Single Unit ('Bubble Car') at the south end: the customary arrangement at present. There's a second Driving Motor Car which is currently receiving attention in Shackerstone M.P.D. before being reunited with its 'other half' to form a 2-car unit. The set normally has four 150 h.p. in use, one to each bogie but one engine on the Single Unit has been using excessive engine oil for a while and the Owner recently decided to isolate that engine and run with three engines until a replacement engine could be fitted.

The thoughtful design of the 'Modernisation Series' DMUs makes it easy for a driver to safely isolate an engine which has failed in traffic, allowing the unit to 'limp home' with reduced power and this had already been done. Firstly, the Final Drive had been isolated using the hook-ended, long-handled tool stowed in the guards compartment.

Guard's compartment in 55005: The long, thin rod with a handle at the top stowed vertically in between the red-painted Brake Setter and the Guard's seat is the 'Toasting Fork' to isolate the final drive.

The 'toasting fork' allows the driver to reach over the top of the bogie, grasp the isolating switch with the hooked end and twist the switch to the 'isolated' position.

The vertical bar is the Final Drive Isolating Switch in the 'engaged' position. When horizontal, the drive is 'isolated'.

Secondly, a carriage key had been used to electrically isolate the engine, using the isolating switch on the underframe near the engine.

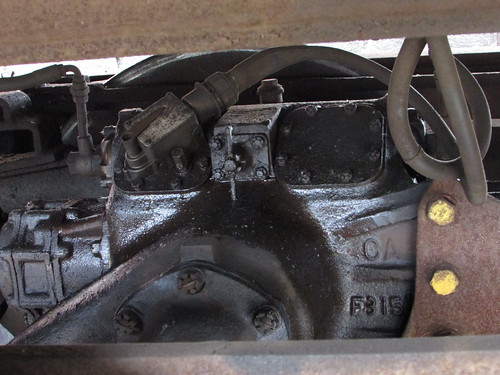

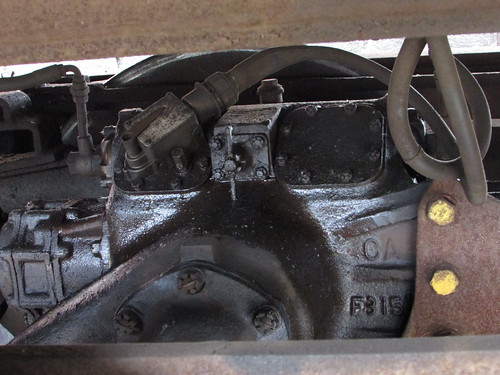

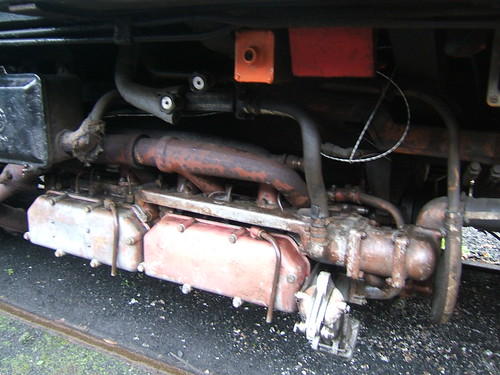

'Flat 6' DMU engine. The orange-painted square box mounted on the underframe above the engine is the switch (operated by a carriage key) to electrically isolate the engine.

It didn't take long to check oil and fuel levels, make sure auxiliary drive belts were intact and look for anything not quite right, then each engine was electrically started from the ground. Two out of three started: one refused to turn over and just made an 'Ug' sound. I started thinking about finding the battery charger and setting it up to get more life into the battery but decided to make one more attempt and this time the engine turned over sluggishly but enough to fire and we were away.

Stephen W. was booked Guard and he arrived nice and early. The day started dull and rather cold so we anticipated poor passenger numbers but when we moved the train from the DMU siding where preparation is carried out into the platform, there were quite a few passengers already waiting. We set off a few minutes late and, for a time, the weather deteriorated with intermittent heavy rain, requiring the use of the air-operated windscreen wiper. Market Bosworth had been closed to passengers during the limited operations as Covid restrictions were eased but we were scheduled to resume the intermediate stop. Whilst waiting for the Guard and Market Bosworth Station Staff to conclude station duties, I took a picture of the passenger compartment behind the driving cab.

Battlefield Line 2021: DMU on 2-Oct-2021 at Market Bosworth on the first northbound service.

We carried on to Shenton with improving weather. In fact, later in the day there was quite a pleasant sun. The dull start to the day made me anticipate poor passenger numbers but quite a few passengers turned up for each service which made the whole day very worthwhile. But I'm sure the passengers were relieved that the carriage heating was working! There are two underframe-mounted heater units on each coach. Diesel fuel (electrically ignited) is burned in a cylindrical combustion chamber and electric fans blow warmed air through ducts into the coach. The heaters are controlled from a simple panel in the Driver's cab and a switch allows fan-only operation in summer. Safety circuits are provided to ensure correct operation. The principle is similar to some warm-air portable heaters used in industry.

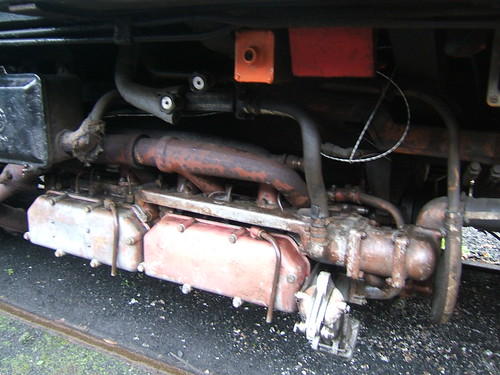

One of the two underframe-mounted heater units on each coach.

One of the two underframe-mounted heater units on each coach.

Stopping at Market Bosworth on the return trip, we picked up a large family group celebrating the birthday of one of the group. They were all staying at the Bosworth Hall Hotel in Market Bosworth and they'd decided to have a round trip on the train. The jolly crowd left us at Market Bosworth on our second north bound journey.

Battlefield Line 2021: DMU on 2-Oct-2021 showing a birthday party alighting at Market Bosworth from the second northbound service.

Our Guard had recently been passed-out to drive the DMU but had not yet had a rostered driving turn so we agreed to 'swop roles' for the third round trip so that Stephen could drive whilst Jan carried out the guard's duties.

Battlefield Line 2021: DMU on 2-Oct-2021 showing Jan completing the Guard's Journal on the third round trip.

I was back in the cab for the final round trip to Shenton then the unit was stabled in the DMU siding, final inspection made and paperwork completed after an enjoyable shift.

Related posts in this blog

All my Battlefield Line posts.

All my DMU posts.

My pictures

Battlefield Line 2021.

All my Battlefield Line pictures.

I was rostered as steam relief driver on 29th August 2021. Because of the Covid-19 Pandemic, this was the first time I'd been on a steam locomotive since August 2020 (described here). Once passenger operations at the Battlefield Line resumed in 2021, I'd been rostered on the Diesel Multiple Unit a few times but, still recovering fitness after the long period of restrictions on life, I'd not undertaken a steam turn before in 2021.

Well, rather than being just relief driver, it transpired that it would help if I covered the whole turn, which I did and thoroughly enjoyed the shift. I was helped by having Stephen W. as fireman who was both willing and capable and we both had a good day.

Previously, I'd only had two turns on 'Wightwick Hall'. The first was on 15th December 2019 (described in the latter section of the blog here). The second turn was on 28th December 2019 (described here).

The locomotive had been left outside the shed so as I hauled myself up the footsteps into the Hall's cab for the first time in 20 months, it was with a sense of excitement. A broad smile spread across my face - I felt at home. Although I knew the fireman would have already carried out the initial checks (tender hand brake applied, regulator closed, cylinder drain cocks open and gauge frame indicating satisfactory boiler water level), I repeated them. The fireman had reported no boiler leaks but a fair amount of ash and clinker on the grate from the previous day's fire. I opened the firedoors to confirm the situation.

Although the firebox was still fairly warm from the previous day, Stephen decided to go into the firebox, lift one or two firebars and push the remains of the previous fire through the opening created into the ashpan. Working in any confined space is potentially hazardous and may only be carried out with a second person on hand. The old fire was disposed, the firebars replaced and Stephen quickly left the firebox.

Preparation

The term 'Preparation' refers to the duties of both driver and fireman in getting a locomotive ready for traffic. Although driver and fireman have defined responsibilities, it's much better when the crew work as a team. I've talked about steam locomotive preparation in a number of earlier articles and a few are listed below.

Driving Turn at Peak Rail - Part One: Preparation

Preparation of Locomotive 'Sapper'

Preparing 5542 (part 1)

Preparing 5542 (part 2)

Articles with the label MIC discuss various aspects of working on steam locomotives. There's an index of these here.

Whilst Stephen prepared to set the new fire, I began 'oiling round', starting with the sight feed lubricator mounted on the driver's side of the boiler backhead. I drained the condensate and filled the reservoir with cylinder oil (also called 'steam', 'black' or even 'thick' oil). This is a compound oil, typically with an SAE of 680 or above, which retains its properties when in contact with steam in the cylinders.

6989 'Whitwick Hall': Sight feed lubricator

Next, armed with an 'oil feeder', 'bottle' of motion oil and a 'wiper' I continued oiling the outside motion and axleboxes from ground level. It always facinates me how different trades develop their own vocabulary and locomen were no exception. The 'oil feeder', of course, is the spouted container used to dispense oil where required, called elsewhere an oil can. The 'bottle' is the tinplate oil container with carrying handle and cork retained by a short chain used to replenish the feeder as required. Motion oil is much thinner than cylinder oil, typically with an SAE of 220. The 'wiper' refers to the woven, absorbent cloth originally issued by loco stores for removing excess oil during preparation, acting as an insulating pad when handling hot objects or for general cleaning. An elderly engineman I knew asserted that a 'proper engineman' could always be identified by the wiper permanently clutched in one hand. These days, rags are often substituted for the traditional wiper.

I then transferred operations to the narrow walkway around the boiler called the foot-framing (the terms 'foot board' or 'running plate' are sometimes used), which allowed various other oiling points to be dealt with. A feature of Great Western engines is the mechanical vacuum pump, driven from one crosshead.

6989 'Wightwick Hall': Detail of crosshead-driven vacuum pump

On the 'Hall' class, there is an oil pot with a T-handled screw cap protruding through an access hole in the foot-framing on the driver's side which provides lubrication for the pump. Usually, a mix of lubricating oil and paraffin is used for this task to minimise the risk of the internal pump air valves sticking. These air valves are responsible for the distinctive 'phut-phut' noise of Great Western locomotives in motion, particularly noticeable when an engine is 'drifting' with the regulator almost closed.

6989 'Wightwick Hall': Right leading splasher showing cut-out in foot framing to give access to the vacuum pump oil pot

It's particularly important to remain alert when working on the foot-framing. Support is available from a handrail run along the length of the boiler cladding on both sides of the engine but, when kneeling to administer oil as required, it's all too easy to lose balance and it's a fair drop to the ground.

Many years ago, I learnt that lesson when getting 'Clun Castle' ready for 'Learn to be a Driver' courses at Tyseley. Now, Sam Ell's work at Swindon on draughting locomotive boilers and improving efficiency resulted in 'Clun Castle' having a double chimney and 'high superheat'. The raised steam temperatures led to the use of a mechanical lubricator mounted on the foot-framing on the fireman's side to dispense cylinder oil to cylinders, valves and regulator (rather than the normal Great Western sight feed lubricator which the original single-chimney 'Castles' retained). Mechanical lubricators are excellent but can result in oil on the foot-framing from carelessness during filling of the reservoir or vibration-induced oil line gland leakage. I didn't notice a film of oil around the lubricator, lost my balance and ended up on the floor, on my back, looking at the sky with severe pain from the near rail of the adjacent road pressing into the small of my back. I was lucky, I was able to get up and carry on with my shift (in some discomfort) but the consequences could have been serious.

By the time I'd finished 'on top', Stephen had the fire well in hand and he offered to complete the vital oiling 'underneath'. The 2-cylinder 'Hall' has Stephenson Link motion with four eccentrics mounted on the driving axle between the frames to provide the necessary valve events to dieblocks in the expansion links. With outside cylinders and valves, as used on the 'Hall', rocking shafts are required to transmit the movement of the dieblocks between the frames (via the intermediate valve rod, rocking shaft, valve link and valve rod) to the piston valves outside the frames, as described here.

There wasn't a great deal of coal in the tender but well over 3,000 gallons of water. Stephen wasn't quite sure whether we'd complete the diagram (four round trips to Shenton) without more coal but we agreed to come 'off shed' onto our train and see how things went.

In Traffic

Unusually, we were running with a 6-coach train which meant we would 'overhang' at platforms, so I discussed with our Guard the stopping points he required to make his job easier in making sure passengers could safely board and alight.

Creating vacuum to release the brakes was noticeably slower than normal. There's a post about the Great Western vacuum brake here. Both small and large ejectors are provided. Normally, I'd only use the small ejector and judge any leakage in the train braking system by the rate at which indicated vacuum climbed, but the 'little jet' alone failed to produce the necessary 25 in/Hg (inches of mercury - measure of the vacuum produced) so the 'big jet' was also needed.

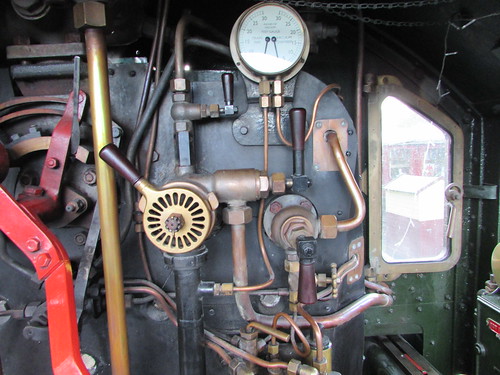

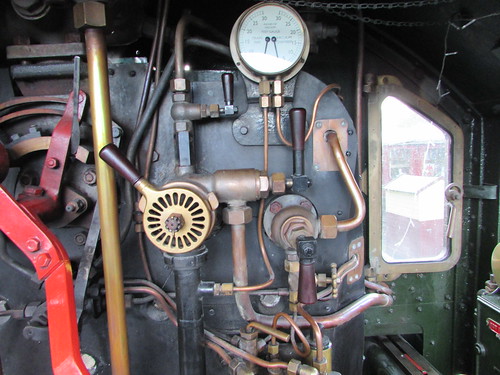

6989 'Whitwick Hall': Driver's vacuum brake application valve with radial slots to admit air, small ejector steam cock (above), large ejector steam cock (right) and blower valve (below right)

Opening either ejector steam cock admits steam to the multiple-cone ejector mounted on the driver's side of the firebox. Convergent cones in the injector body produce a jet of fast-moving steam which draws air out of the train's vacuum pipe, discharging the steam and extracted air through the pipe running horizonally along the boiler cladding to the smokebox where an elbow takes the steam/air into the smokebox to be discharged vertically through the chimney. A carefully-designed system of copper drain pipes seeks to allow condensed steam to be drained downwards but when the large ejector is first turned on, it's wise not to be near the front end of the locomotive as a shower of water may be discharged (as generations of platform-end-dwelling train-spotters learned in steam days).

6989 'Wightwick Hall': View from cab showing right side of firebox and vacuum ejector

Our first departure was booked for 11:00. I think we were a little late away waiting for passengers and then I made a gentle departure. With the cylinders cold, condensate can be anticipated in the steam circuit so the cylinder drain cocks ('taps') should be open to allow live steam to clear this condensate. Moving a train away from a platform is always the time of greatest risk when passengers may change their mind and try to get off or, perhaps worse, suddenly decide they want to get on. The Guard and Station Staff should have checked that all doors are properly closed with no handles 'cocked' (no central locking here!). Years ago, I was taught that if there are sufficient platform staff available, one should be positioned fairly near the departure end of the platform to 'chase' any door handles spotted as not properly closed. Getting under way gently is certainly desirable with 'Wightwick Hall' as she has an irritating habit of 'losing her feet' when starting and this is aggravated by the open cylinder drain cocks liberally wetting the rails ahead. Even six coaches is still a light load for a 'Hall' so, although I'd started away in full forward gear, I quickly 'wound it back' a little on the screw reverser to give an earlier 'cut-off' of live steam during each piston stroke. The fireman collected the staff from the signalman, I made sure the 'section signal' (as they now call signals admitting you to the next signalling section) was 'off' and we proceeded through the 10 m.p.h. cutting section up to Barton Lane Bridge. Once in motion, the vacuum pump will be attempting to make up losses but until speed is above 15 m.p.h., its contribution is uncertain. Normally, the small ejector will be more than enough to hold the regulation vacuum of 25 in/Hg and prevent brakes from dragging on.

A little beyond the bridge, Line Speed (25 m.p.h.) is now authorised by a cut-out '25' speed marker sign, following permanent way work and tamping of the line and this happy state now extends to the platform at Market Bosworth. Of course, that increased speed only applies when the whole of the train has passed the sign. Glancing back to check we were clear, I tugged the regulator to 'full first valve'.

Slide valve regulators have two flat valves to control the steam, both operated from a common handle. Initial movement of the regulator handle opens a smaller steam valve (called 'pilot', 'first' or 'starting') which varies the steam port size in proportion to angular regulator handle movement. At full first valve, there is resistance to further movement but a determined 'pull' will start to open a second, larger steam valve (called 'main', second or 'big') which significantly increases steam flow. Larger Great Western locomotive designs, like the 'Hall', place the two regulator flat slide valves horizontally in the smokebox, with a separate oil line from the sight feed lubricator in the cab to the regulator assembly to minimise the driver's adjustment effort as far as possible. There are a couple of articles which give an introduction to the various types of regulators in use.

Locomotive Regulators (part 1)

Locomotive Regulators (part 2)

As speed slowly increased, I wound the reverser to the recommended 'Drifting' position, marked by a stud attached to the engraved cut-off scale showing percentage cut-off.

Many valuable historical records of train performance were meticulously prepared and published by enthusiasts. When they were permitted to actually travel on the footplate, they would carefully log indicated cut-off, regulator opening (estimated by the angular position of the regulator handle against the quadrant) and frequently boiler water level/shovelfulls fired. These make fascinating reading but every old-time driver I've spoken to over the years has confirmed that few, if any, drivers took any notice of indicated cut-off, adjusting the controls until "it felt right". The indicated cut-off was not always accurate and I was told that the cut-off indicator on some Bullied engines was called "the biggest liar on the footplate".

With the light loads, low maximum speed and moderate gradients on the Battlefield Line, I've normally found that the regulator at 'full pilot' and reverser at 'drifting' will do the job and, once 'Line Speed' is achieved, the regulator can be banged closed then eased open enough to open the lubricator jockey valve to ensure oil continues to feed the pistons and valves whilst coasting. If speed starts to fall earlier than required, the regulator cab be re-opened but, depending upon the rolling resistance of the train (a combination of friction in all the wheel bearings on the train, direction and strength of any wind and any defects like dragging brakes), once Line Speed is achieved somewhere near Headley's Crossing, the train will coast to Market Bosworth, where's a speed restriction of 10 m.p.h. when any part of the train is alongside the platform. Correctly judged, this speed can be achieved by braking as the locomotive approaches the platform, performing final braking so as to stop the train in the platform. It's vital that the train is prevented from moving during this intermediate stop, either by destroying the vacuum or applying the tender hand brake. At Market Bosworth, the platform is on the driver's side, so the driver can monitor the progress of passengers getting off and on. Market Bosworth station platform will accommodate a five coach train so, with 'six on' a different stopping point was chosen, leaving half a coach off the platform each end.

Whilst waiting, I wound the reverser into full forward gear ready for starting away. The Great Western screw reverser can be a delight to adjust but I do find the one on 'Wightwick Hall' rather stiff. A long time ago I was spoilt by working on restored Castle Class 'Defiant' which had the easiest-to-adjust screw reverser of any Great Western locomotive I've worked on (together with a regulator offering genuine 'finger-tip' control, unlike the claims often made for 'balanced' or 'double-beat' types). However, my all-time award for easiest-to-adjust screw reverser goes to preserved LNWR number 1054, the Webb 'Coal Tank', where the Stephenson valve gear is adjusted by a reversing screw with a Triple-Start Thread. When I drove this lovely engine, the only problem was the absence of a handle latching mechanism, so I had to drive leaning against the handle to prevent it from self-adjusting to full gear! But that's another story.

Having received the 'Right Away' from the guard, I 'blew the brakes off', whistled, checked that the foot crossing ahead was clear and partially opened the regulator. As we moved away, I adjusted the reverser for an earlier cut-off, occasionaly looking back along the train until all coaches were clear of the platform. Leaving Market Bosworth, there's still a 15 m.p.h. speed limit over the Cattle Creep Bridge just before the turnout to Deer Park Siding so I didn't let speed rise above this until the whole train was clear of the bridge, then I set the regulator to 'full first valve' and let speed increase.

We'd been told that rain following cable laying operations between Market Bosworth and Shenton during the previous week had resulted in some displaced spoil near the running line. Although an inspection run with a diesel locomotive the previous day had passed the line as fit, some caution was advised on the first trip so I 'reined her in' as we approached the works site and we drifted through carefully, the fireman and I satisfying ourselves that all was good. Once past the works site, a little steam was needed to pick up speed then, with the reverser at 'drifting' the regulator was closed ('cracking' it to open the lubricator jockey valve) and we coasted down Shenton bank towards our destination.

The severe 5 m.p.h. speed retriction between Ambion Lane bridge and Shenton station caused by embankment slippage remains in place, so the aim was to brake sufficiently to comply with the 'slack' whilst leaving sufficient monentum to keep rolling along the platform to the 'six on' stopping point with the locomotive blocking the foot crossing.

On arrival, it's important that the Guard immediately applies the Guard's Screw Handbrake to prevent movement of the coaches whilst the engine runs round its train. I set the engine in back gear and partially released the brake so that The engine could be 'eased up', compressing the buffers between tender and coach in an attempt to slacken the screw coupling, making detaching the locomotive a bit easier for the fireman. There's a short post on coupling and uncoupling here.

The Guard collected the Single Line Staff, which he needed to work the ground frame at the north end of the run-round loop, and the Fireman walked forward to work the hand points at the south end of the run-round loop. With Driver, Fireman and Guard working together, the engine was transferred to the north end of the coaches then Stephen 'hooked-on" and set the lamps for our tender-first return to Shackerstone. Having reset the ground frame for the running line, the Guard passed the Single Line Staff back to the footplate crew, together with confirmation that 'permission to return' had been received from the Shackerstone signalman by telephone. Once all the passengers had been shepherded onto the train and the doors closed, the Guard gave the 'right away' and we gently started away.

It's a different experience running tender first with the bulk of the tender reducing the view ahead of the train. There's some view over the top of the tender on most Great Western engines (unless freshly coaled to the limit) or the driver can lean out of the cab side. When running chimney-first, leaning out usually gives a reasonable view ahead because, particularly on Great Western tender engines, the boiler is narrower than the footframing. But, tender first, the view is limited by the slab-sided tender with flared top almost the full width of the engine. There's the further complication that the tender is a separate six-wheel vehicle articulated with the engine so its exact position relative to the cab keeps altering in a rather disconcerting fashion and, on left-hand curves, the tender moves to further restrict the view.

Many years ago, observing freight workings in and out of Spring Vale Steelworks when steam still ruled, I learned that there were two types of driver - those who would happily work a train tender-first if it finished their shift sooner and those who would first insist on a light-engine excursion to a nearby triangle to turn, enabling them to work their train chimney-leading. Of course, at the Battlefield Line there's no alternative to working tender first in one direction.

The other factor which becomes quickly apparent when running tender-first on a Great Western is the engine crew's exposure to the elements. Cab designs have evolved from the early days of steam through various stages. Initially, there was no cab at all. The first stage was the introduction of a flat spectacle plate as a baffle against the wind when in motion. Perhaps surprisingly, some drivers objected to this refinement, seemingly enjoying the tough reputation they enjoyed (many early drivers, like sailors, sported luxuriant beards). But levels of weather protection gradually improved, with cab sides and cab roofs increasing in size with time. Churchward cabs were rather spartan but his successor Collett introduced a larger cab used on the 'Halls' and 'Modified Halls' which isn't bad travelling chimney-first but offers little protection when travelling tender-first. In wet weather, a canvas storm-sheet could be rigged between engine and tender but, when travelling tender-first, this can impair the driver's view.

Although it wasn't raining on this occasion, when running at line speed quite a strong wind whipped across the tender (producing plenty of coal dust from the diminishing coal supply) and into the cab. We made the booked stop at Market Bosworth and then continued to Shackerstone where we were signalled into platform 2, stopping with the leading coach just clear of the foot crossing. This meant that the engine blocked the foot crossing and passengers had to wait at the platform end until we'd uncoupled and moved clear before they could move between the two platforms.

We completed the run-round and prepared for the second round trip at 12:30. We'd plenty of water in the tender. This was just as well as our six coach train prevented access to the water crane at Shackerstone. The second round trip was carried out without incident, as was the 14:00 departure. Water level in the tender was still satisfactory but Stephen and I decided we needed to re-coal before the fourth trip as there would be two evening round trips with a dining train operating by a different locomotive crew.

The fourth round trip also went to plan and, before handing over to the evening crew, Stephen and I agreed we'd had a very enjoyable day.

Jan on 'Wightwick Hall', 29th August 2021 (Photo: S. Wallbank)

My pictures

6989 'Wightwick Hal1'

Because of the Covid-19 Pandemic, Trade Shows and Exhibitions were suspended but, following the easing of emergency legislation in July 2021, this type of event was able to resume subject to 'Covid Secure' guidance.

On Thursday 9th September 2021 I attended the last day of the Railtex and Infrarail combined exhibition at the National Exhibition Centre near Birmingham, together with one of my friends from Bath who travelled independently by train.

Getting there

Once again, I took the first bus from Brewood to Wolverhampton at 07:30 and walked to the railway station. For a change, I decided to catch the 'local' to Birmingham New Street. The service currently then continues to Walsall (I described using this circuitous route to Walsall in the post Walsall by Rail). In recent years, platform 5, the bay platform 5 at the south end of the station on the Down side) is used by the terminating 'all stations' Electric Multiple Units along the Stour Valley line but, before electrification and then called 'Down Bay' I think, it wasn't very often used by passenger trains (but I've described catching one Diesel Multiple Unit from this bay during 1962 in the post here). As part of the station redevelopment which accompanied electrification, the end of this bay became a parcels sundries depot, which has now been demolished.

Wolverhampton Station: View from platform 5 showing stop signs, remains of the parcels sundries shed and, in the background, new station in black and orange

There weren't many passengers on the train when I boarded but by departure time at 08:22, the train was reasonably full and at each stop, more people boarded than alighted so we were quite full on arrival at Birmingham New Street. We stopped at Coseley, Tipton, and Dudleyport (all stations I regularly used 60 years ago when making unofficial visits to signal boxes as described in the postVisiting Signalboxes). Stops were then made at Sandwell and Dudley, Smethwick Galton Bridge and Smethwick Rolfe Street. Smethwick Galton Bridge is a relatively recent development, opened in 1995 to provide connections with the 'Jewellery Line'. Over the years, I've occasionally used all six stations between Wolverhampton and Birmingham New Street. Currently, 25 minutes are allowed including stops.

I had expected us to arrive in platform 1 at New Street but discovered it was closed with engineering works on the platform being carried out so we used platform 2. I've complained previously about the confusion that can arise in attempting to change platforms using the stairs or escalators at the 'A' (southern) end of the platforms which seems to involve leaving through the ticket barriers and then coming back in again through another ticket barrier. I was amused to see that signs have now been erected recommending using the 'B' end when changing platforms. With plenty of time in hand, I decided to have another look at the adjacent Grand Central Shopping Centre to see if I liked it any better than on a visit in 2016 described here. I didn't, so I left the station to look at the Midland Metro Tram station in Stephenson Place.

This tram station hadn't been completed at the time of my 2016 visit, but was in use in 2019 when I attended the UKRRIN Annual Conference (described here). However, in September 2021 I was surprised to find the area dug-up again and piles of pre-cast sleepers around. It appeared that the service had been terminated at Bull Street whilst an urgent track relaying along Corporation Street to Stephenson Place was carried out, expected to be completed before Christmas 2021. No explanation was available about the reasons for such major works only five years after completion of build on this section.

Sleepers in Stephenson Place for track replacement (West Midland Metro)

I walked as far as the Town Hall before returning to the railway station along pedestrianised New Street then through the Arcade past the Macdonald Burlington Hotel. When this was still the Midland Hotel it had a decent, old-fashioned restaurant on the first floor overlooking New Street which I used to enjoy visiting for lunch occasionally. On platform 4, I joined a Cross Country 'Voyager' from Manchester, where I was joined by my friend for the 9-minute journey to Birmingham International station. Birmingham International is another relatively recent development, opened in 1976 to serve both the adjacent airport and the National Exhibition Centre.

The Venue

When I started my own business in 1966, all major trade shows were held in London at Olympia or Earl's Court, which were both showing their age. The National Exhibition Centre (NEC) is one of the better ideas promoted by Birmingham City Council, in my opinion. The idea of a new exhibition location on a 'greenfield' site with good motorway, main-line railway and international air connections appealed to me. The first stage was opened in 1976 and expansion up to 1998 now offers 20 exhibition spaces of various sizes, including the multi-purpose indoor Arena which can be used for exhibitions or entertainment events. 'London-centric'-thinking made establishing the venue rather difficult. For instance, in 2000, the ExCeL exhibition and conference centre opened in London and its foreign owners have continued to develop that competing site. In 2014, Birmingham City Council sold the site which is currently owned by the Blackstone Group.

The Exhibition

'Railtex' and 'Infrarail' are two leading exhibitions in the UK aimed at the railway industry. Following the inability to stage this type of exhibition at all during 2020 because of the Covid-19 Pandemic, the two exhibitions were combined under the banner of the 'UK Rail Hub'in 2021. The event was open 7th-9th September in Halls 11 and 12 of the NEC. 'Railtex' was billed as "the 15th international exhibition of railway equipment, systems and services" and 'Infrarail' as "the 13th international railway infrastructure exhibition".

Arriving at the show during the Age of Covid-19 provided a new experience. On the broad, covered overhead walkway connecting the railway station to the NEC, teams of security checked documentation relating to the Covid-19 status of visitors, who were then asked to wear a self-adhesive wrist-strap to confirm a satisfactory check.

On reaching the exhibition halls, registration was quick - I'd signed-up on-line previously and printed out the confirmation which included what used to be called a 'QR Code' (for quick response) but, with wider utilisation for all sorts of purposes, including railway ticketing, is also called a '2D Barcode'. There's an excellent article about these codes on Wikipedia here. A pleasant lady scanned my confirmation at a special pedestal at the entrance which immediately printed a card label which she attached to a lanyard and I was 'in'.

The show was useful but, perhaps understandably, seemed rather more subdued than previous, similar events I've been to. But I found it good that people were starting to meet face-to-face rather than by the dreaded 'Zoom' or 'Teams' video conferencing.

By mid-afternoon, my friend and I had achieved all we'd hoped and we walked back to Birmingham International station. The northbound train we caught was rather full so we stood in the coach vestibule to Birmingham New Street, where my friend had a change of train. The passengers thinned-out somewhat here so I found a seat to complete my journey back to Wolverhampton.

My local railway pictures

West Midland Railways.

As the Covid-19 Pandemic continues, some easement of travel restrictions has allowed me to repeat previous journeys in the United Kingdom to note changes. Having visited Liverpool area (described here) and Blackpool area (described here), I travelled via London to Croydon to visit my friend on Thursday 2nd September 2021, returning the following day.

The day before my trip, I'd managed to book train tickets online, after some difficulty with the booking 'apps'. Government advice was strongly recommending social distancing (and mask-wearing in crowded locations) so I decided to travel First Class.

I took the first bus from Brewood to Wolverhampton at 07:30, which meant I had plenty of time to walk to Wolverhapton's new and rather incomplete station which still fails to impress me. I couldn't help compiling a mental 'snagging list' of features I came across that were either not yet finished or had already broken in use. My childhood visits to the station were to a rather run-down station after the exigencies of WWII but it still provoked a sense of anticipation quite lacking in the 21st century version. There are short posts describing that period here and here.

Wolverhampton Station entrance hall showing the new ticket gateline giving access to platform 1

The departure was from platform 4 and the previous operators of the service, Virgin, had a First Class Lounge there but there isn't one currently. The Avanti website says "Most of our First Class Lounges are currently closed. To ensure safe social distancing, we’ve also reduced the available space in our open lounges".

The train arrived on time - a Glasgow to London via Birmingham service operated by a Class 390 'Pendolino'. I found my reserved seat and settled down. There were only a couple of other passengers in my coach. We departed a couple of minutes late and the on-board staff quickly provided a cup of tea and an instant porridge, which I selected from the rather limited menu. Both were served in cardboard containers with wooden cutlery. In the age of Covid-19, a reasonably 'proper' breakfast served with metal cutlery is a distant memory. The ride quality was not particularly good and I wondered if the fact that I was in the leading vehicle was a factor.

The journey was uneventful and the driver had no difficulty in maintaining the fairly generous timing to London Euston, arriving in platform 16 at 10:33. As we slowly ran in, I had a good view of the adjacent major civil engineering works for HS2, the new high speed railway which will initially link Euston to a new station at Curzon Street Birmingham. The former Down side carriage shed and associated sidings have been removed and the site is being prepared for the new line. I'm a great believer in railways but can find no justification for proceeding with HS2 when many parts of the country are crying out for more investment on existing, conventional routes.

Euston in 2013 with the disused Down Side Carriage Shed in the background.

The present Euston station has become rather down-at-heel, despite periodic refurbishment. Some years ago, a major rebuilding was promised but this will presumably coincide with the eventual completion of the first stage of HS2, whenever that is. There's a short post from 2008 discussing Euston, St. Pancras and King's Cross here. The concourse area at Euston has escalators leading directly to Euston Underground station but, at present, a detour is needed. All passengers are first directed outside, make their way along the outside of the building, then re-enter further along to reach the escalators. Builder's partition walls ensure this detour. I found the signage rather inadequate and the impression conveyed is that 'Customers' (as the railway prefers to term its passengers) are really rather a nuisance.

It was quite busy in the ticket hall of the underground station, mainly people apparently bewildered by the array of automatic ticket machines along one wall. The 'Oyster' contactless ticketing system is now extended to to allow 'touch-in' by credit card, allowing me to avoid the confusion and descend to the southbound Victoria Line platform where a train arrived after less than a minute. Despite the drop-lights at each end of the coach being lowered for ventilation and noisy fans in the ventilation system apparently turned up to maximum, it was a very warm journey to Victoria and I was quite relieved to return to ground level and the comparatively spacious concourse at Victoria.

Even today, the history of Victoria station as two stations side-by-side is apparent in its layout and architecture. On the eastern side, a pleasant arched roof covers the 'Chatham' lines (shared by the London and Chatham Railway and South Eastern Railway prior to their amalgamation). To the west, there's an impressive range of station offices built to serve the 'Brighton' lines of the L.B.S.C.R. which feature the heraldic shield of Sussex but the platforms themselves are now permanently without natural light following the construction of a modern building overhead.

London Victoria: Heraldic shield of Sussex featuring six martlets on the western range of offices on the Brighton side.

There's a brief article about the origins of Victoria Station here. I joined the next 'fast' train to East Croydon and within a few minutes we were on our way. We made the single mandatory intermediate stop at Clapham Junction which I've briefly described in a earlier post here. Around ten minutes are allowed from Clapham Junction to East Croydon but we were brought to a stand by a red signal just after Selhurst and then again just before East Croydon.

East Croydon: View from platform 4 looking towards Brighton in 2016

A short taxi ride then completed the journey to visit my friend - a visit delayed by almost 18 months because of the Covid-19 Pandemic.

The following afternoon, I returned home. This time I decided to catch the bus from my friend's to East Croydon station. The next train to Victoria was running a few minutes late and by the time it arrived, the platform was crowded, adding more passengers to the already-full train. I decided to remain standing for the journey to London. There were more people swarming around Victoria station than the previous day. When I reached the underground, I found an alternative access route was in use from the ticket hall to Victoria platform level, necessitating a fairly long detour through pedestrian tunnels. The train was well-loaded but I found a seat and, once again, the underground journey was hot and noisy. I arrived at Euston main line station in plenty of time for my booked train, then was pleased to discover that the Avanti First Class Lounge at Euston was still operating, providing a pleasant haven for a few minutes and offering drinks and snacks served by friendly staff. I was booked on the Edinburgh via Birmingham service which would deliver me to Wolverhampton without a change but, on making my way to the platform, I found two diesel-electric 'Super-Voyagers' (Class 221) units coupled together rather than a single electric 'Pendolino' (Class 390) unit.

I'm not sure whether this was a 'substitution' - certainly the reservations for a number of passengers (including the writer) had gone wrong but the on-board staff got everybody in my coach seated with some empty seats remaining. With underfloor diesel engines along the train, 'Voyagers' are always noisier than the 'Pendolinos' but what particularly annoys me is that the diesel-electric trainsets would be travelling "under the wires" from London to Scotland but using diesel fuel. This is because successive UK governments have declined to 'grasp the nettle' of comprehensive railway electrification despite a stated commitment to "de-carbonise" the economy. Instead, we now have the ultimate 'cop-out' of the later Hitachi 'Azuma' trains built for the UK (the Class 800 series) which are 'Bi-mode' and can run on overhead electrified lines or on non-electrified lines using diesel engines and electric generators. When running on overhead electrified routes, they suffer the weight penalty of lugging around unused diesel engines, generators, fuel tanks and fuel. When running on non-electrified lines, there's the weight penalty of the high-voltage switchgear and transformer. The increased complexity of 'Bi-mode' adds to both initial and maintenance costs.

In 2020, when rail journeys for non-essential purposes were prohibited by law, I remotely monitored movements at Euston a few times during the reduced 'Covid-19' timetable using Railcam UK (described in my post Watching The Trains Go By). There are two posts on those observations here and here.

By September 2021, more trains were being run but still fewer than in 'normal' times. However, the pair of Class 221s got me back to Wolverhampton on time. Rail travel in the age of Covid-19 is a little strange but at least it's possible.

My last previous visit to Blackpool was on Saturday, 9th February 2019. That visit is described here. The Coronavirus Pandemic put paid to thoughts of another visit in 2020 and it was not until the second half of 2021, following easing of government restrictions, that I made another day trip.

To help comply with government advice on continuing social distancing, I decided to book First Class Advance tickets online beforehand with Avanti, operating the same fleet of Class 390 electric multiple units previously used by Virgin (but re-liveried). On my 2019 visit, it had been electric traction by Virgin to and from Preston then Northern diesel multiple units the rest of the way. However, under the present Pandemic timetable, some Avanti services operate through to Blackpool North offering electric traction throughout without need for change.

I caught the 08:35 bus operated by Select from Brewood to Wolverhampton and walked to the station. The pedestrian route approaching the station entrance is still narrow and inconvenient because of the building site immediately outside which I presume is caused by work to finish the tram terminus but progress appears very slow.

Wolverhampton Station. The tall building in the background is student accommodation for the university (Blackpool by Electric Train)

Wolverhampton Station entrance hall with ticket gates in the background (Blackpool by Electric Train)

My train an Avanti 'Pendolino' Class 390 reporting number 9P47 arrived a few minutes late, its timekeeping presumably not enhanced by following the 'All stations' local train from Birmingham which pulled into platform 5 bay shortly before my train arrived. Our first stop was Crewe so, as expected, the lateness was easily recovered by the time we paused in platform 11. On leaving Crewe, just 16 minutes were allowed to our Warrington stop, where the massive Unilever plant dominated the skyline on the down side. It was only later that I discovered the site had closed in October 2020. Apparently, demand for soap powders has reduced with users switching to liquids and capsules so a 139-year history of soap-making at the site, still locally referred to as 'Crosfields' has come to an end.

The Unilever plant in Warrington which closed in October 2020 (Blackpool by Electric Train)

A further 9 minutes took us to Wigan North Western, crossing under the historic Liverpool and Manchester railway line, the first main line railway in the world on the way. The station name distinguished the London and North Western railway's faciliites from Wigan's second station operated by the Lancashire and Yorkshire Railway named Wigan Wallgate, after its location. The two railways were merged into the London Midland & Scottish Railway in 1923 and it always delights me that the station name 'Wigan North Western' survives almost a century later.

Class 331 in platform 5 at Wigan North Western forming 2C10 to Liverpool (Blackpool by Electric Train)

The last calling-point before our destination was Preston reached in 12 minutes from Wigan. Finally, a generous 28 minutes were allowed for the last leg to Blackpool North, reached in bright sunshine. I noted that The train was due to leave again at 11:48 forming train 9M53 to London Euston due 15:33. Modern rolling stock is fairly intensively utilised.

Blackpool North Station, with passengers streaming off recently-arrived Class 390 in platform 1 and a Class 331 in platform 4 (Blackpool by Electric Train)

I made my way out of the station and found the pedestrian underpass under High Street closed, leaving the rather narrow series of ramps to Talbot Road as the exit. Various temporary arrangements for road traffic had been made and it became clear that although the former Wilco building had been demolished, the planned new tram terminus I'd learnt about on my last visit in 2019 was nowhere near complete and the new hotel to be operated by Holiday Inn had only reached the stage of some structural steelwork erected. The double track tram line from the promenade reached an inset scissors crossover in course of installation.

Scissors Crossover being installed at Blackpool North Tram Station building site (Blackpool by Electric Train)

I walked down Talbot Road towards the Promenade past plenty of holiday-makers enjoying the good weather. I noted that no overhead conductor had yet to be fitted on the 'new' tram lines and at Talbot Square, where the extension to the railway station makes a triangular connection with the existing route along the Promenade, there were more temporary road traffic arrangements. I'd found that the modern trams were running five an hour each way, so I managed to reach the North Pier tram stop just before a tram to Fleetwood arrived. I always enjoy the tram ride to Fleetwood, past Blackpool's well-known hotels.

Imperial Hotel, Blackpool (Blackpool by Electric Train)

After passing through through Cleveleys the tram route turns away from the coast and enters Fleetwood threading through Lord Street, the main shopping street looking a little shabby after difficult economic times, finally terminating at Fleetwood Ferry adjacent to the small public Euston Park, in front of the imposing North Euston Hotel and in sight of the estuary of the River Wyre.

I walked across to the entrance to Fleetwood Ferry and realised that the small ferry at the slipway was loaded with passengers. I checked the chalkboard displayed and found the ferry was just about to leave, although I was puzzled to read 'Last ferry 1.45 pm' which seemed rather early. A sign indicated I should pay the fare on the ferry so I hurried down the slope to the ferry, joining a man who'd just emerged from the ferry building who I realised was the Ferry Captain. At the gangway, I paid the two pound fee to the other member of the two-man crew, the gangway was raised agains the side of the ferry and within seconds we started our 5-minute crossing of the mouth of the river, about a quarter of a mile. I'd not been on this fairly modern ferry before, broad-beamed with bench seats on all four sides (apart from where the gangway was fitted on the port side). The 'bridge' was a small podium on the port side in the passenger saloon provided with a raised, windowed lookout all-round. Access to the bridge was via a short, vertical ladder. The benches accommodated about thirty passengers, leaving space in the middle for pushchairs and bicycles. It was all rather homely.

View of Fleetwood from the Knott End Ferry with the Upper Lighthouse or Pharos in the background (Blackpool by Electric Train)

Using the optical zoom on my camera, I managed a reasonable shot of the two nuclear power stations at Heysham, about 9 miles away in a direct line (but much further by rail or road), reminding me of my last visit to Heysham in 2019 described in the post Morecambe by Rail

View of the two nuclear power stations at Heysham from the Knott End Ferry (Blackpool by Electric Train)

The ferry pulled alongside the concrete slipway at Knott End and the passengers disembarked. As passengers boarded for the return journey, I was able to take a picture of the ferry, named 'Wyre Rose'.

The Knott End Ferry 'Wyre Rose' loading passengers at the Knott End Slipway (Blackpool by Electric Train)

Before walking up the inclined slipway, I took a picture to try to capture the elegant proportions of Decimus Burton's Queen's Terrace in Fleetwood.

Queen's Terrace, Fleetwood, viewed from Knott End Slipway. The Terrace was designed by Decimus Burton and completed in 1844 (Blackpool by Electric Train)

The lower part of the slipway was wet and covered with fresh sandy mud and seaweed, making me realise why the last ferry was at 1.45 - the tide was still going out and this seemed to be confirmed by the length of exposed slipway before reaching land.

Landward view from Knott End Slipway: (L) modern apartments (R) Knott End Cafe and H. M. Coastguard (Blackpool by Electric Train)

Wishing to return on the ferry before it stopped, I cut short my visit to Knott End. I decided I might not have sufficient time for something to eat at the Knott End Cafe so, instead, I sat in the sun taking in the view of the River Wyre and Fleetwood as the ferry crossed to Fleetwood, took on a fresh complement of passengers and came back to Knott End. As I started to make my way back down the slipway, I was joined by quite a few other passengers. As the ferry came alongside, I was surprised to see a generous discharge of water from a hose controlled by the crewman which I concluded was to remove the worst of the sandy mud and seaweed from the slipway at the landing place. The crewman held out a plastic bucket for the two pound fare whilst the captain offered each passenger a squirt of hand sanitiser. We were soon under way on our short crossing.

The Knott End Ferry 'Wyre Rose' returning to Fleetwood showing the offset 'bridge' and passenger saloon (Blackpool by Electric Train)

Back at Fleetwood, I decided a light meal was indicated. A short walk took me to the Cafe Royal on Bold Street, which proved a wise choice. Suitably refreshed, I made my way south along Upper Lune Street, past the walled premises of Fleetwood Bowling Club which was established in 1880 and has two crown bowling greens set in a private location, stopping to record the distinctive Upper Lighthouse. Wikipedia has a short article here.

The Upper Lighthouse or 'Pharos' at Fleetwood (Blackpool by Electric Train)

I then walked along Queen's Terrace to Fleetwood Museum, housed in the Grade II listed former Customs House, where I spent a very enjoyable hour or so studying the excellent, varied displays about Fleetwood and its history and chatting to the knowledgeable staff. The museum website here gives more information about this splendid museum.

Former Custom House at Fleetwood, built 1838, is now Fleetwood Museum (Blackpool by Electric Train)

Although I was quite near the well-known Fleetwood Market, I decided against a visit on this trip and I was not tempted to make the longer walk to the 'shopping village' which used to be called Freeport Fleetwood but is now 'Affinity Lancashire', one of 45 outlets owned by Global Mutual. My post here describes a visit to the 'shopping village' in 2016. Instead, I walked back to the Fleetwood Ferry (where 'Wyre Rose' was moored up until the following day) and spent a while on the sandy beach next to the odd-looking River Wyre Launching Facility which is part of Fleetwood Nautical Campus, presumably used for safety training.

River Wyre Launching Facility viewed from the shore (Blackpool by Electric Train)

It was very peaceful as I watched an unidentified Stena Line Ro-Ro ferry slowly making its way towards Heysham but, noting the time, I made my way back to the tram stop I'd arrived at and boarded the waiting tram for the journey back to Blackpool.

View from Fleetwood beach, with remains of the Wyre Light on the right and Stena Line Ro-Ro ferry in the distance making for Heysham (Blackpool by Electric Train)

As we neared Blackpool, the famous Blackpool Illuminations were nearing readiness. In 2021, following the disruption caused by the Covid-19 Pandemic, 'The Lights' are to have an extended season extending from 3rd September 2021 to 3rd January 2022.

View from my tram of just one of the illuminated displays, this with a Egyptian theme (Blackpool by Electric Train)

I left the tram at North Pier and walked towards the Tower for the obligatory photograph, managing to include one of the preserved trams carrying out a 'Heritage Tour'. Whereas the modern trams are serviced at a new depot at Starr Gate, the Heritage Trams remain at the original tram depot at Rigby Road. My post in 2019 here mentions the Rigby Road Depot.

Blackpool Tower with one of the preserved trams on a 'Heritage Tour' departing from the dedicated 'Heritage Tram Stop' marked by the green sign attached to the lamp post (Blackpool by Electric Train)

I took a picture of the North Pier with the tide out, chatted to an inquisitive seagull who flew off once he realised I'd nothing edible and made the customary brief pilgrimage to North Pier before deciding it was time to walk back up Talbot Road to Blackpool North Station for the 17:47 Avanti service back to Wolverhampton.

Blackpool North Pier with the tide out (Blackpool by Electric Train)

Blackpool North Pier (Blackpool by Electric Train)

Before descending the steps and ramp leading down from Talbot Road to the station forecourt, I paused to take in the scene. The train I was to catch had not yet arrived from the south. The warehouse-like main station building is without architectural pretension but does provide an unemcumbered concourse area with good natural light, set at right angles to the terminal platforms outside accessed through a series of doors.

The main building at Blackpool North Station covers the concourse area and is set at right angles to the terminal platforms seen on the right (Blackpool by Electric Train)

By the time I'd made my way to the station and passed through the ticket gateline onto the concourse, my train had arrived and passengers, most with wheeled suitcases, were streaming out. Almost immediately, staff allowed the waiting queue onto the platform to board the train.

Passengers leaving the recently-arrived Class 390 as departing passengers board (Blackpool by Electric Train)

I settled byself in the reserved seat and after a few minutes, we set off, making good time to Preston where we were stopped for a few minutes at signal PN126 - the last signal before entering the platforms. We made our booked stops at Wigan and Warrington then at Hartford Junction we passed a stationary train on the Up Slow of West Coast Railways stock hauled, I think, by a Class 57 on some sort of special, apparently waiting for us to precede it on the double track section. I had time to use the live display provided by Railcan UK to identify the special as 1Z57 then, approaching Crewe, we were stopped for a few minutes at signal CE144 - the last signal before entering the platforms. After a short wait, we were allowed into platform 5. Just before we left platform 5, I captured the Railcan UK screen on my mobile, showing my train (9M59) on the right and the special (1Z57) held, as we had been, at signal CE144.

Railcam UK shows the situation at Crewe station as my train (9M59) is about to leave platform 5 (Blackpool by Electric Train)

Click for larger view

As we spooled off the miles to our Stafford stop, Railcam UK showed me that 1Z57 had crossed to platform 11 at Crewe - the platform usually used by 'specials'.

Approaching Stafford, my train was given precedence over a Cross Country 'Voyager' from Manchester on the Up Slow which followed my train to Wolverhampton.

Just north of Wolverhampton, we were once again brought to a brief stand before being brought into platform 4. I left the train after a splendid day out and caught a taxi home.

Wolverhampton, showing 9M59 from Blackpool in platform 4, ready to go forward to London Euston (Blackpool by Electric Train)

Related posts on this website

Blackpool by Train (Visit in 2019).

Return to Blackpool and Fleetwood (Visit in 2016)

A Trip to the Seaside (Visit in 2014)

My pictures

This trip:-

Blackpool by Electric Train

Depending on the display device, the right hand edge of pictures may not display. To see an uncropped image, click on the picture. Alternately, you can find the image by following the 'My pictures' link and display or download the image in various resolutions.