This is a list of the occasional posts I've written about Diesel Multiple Units (DMU), based on my experiences at the Battlefield Line. Content is mixed, sometimes including associated steam train working.

Posts are listed in reverse date-of-posting order but, just to confuse, each post describes events any time from the previous day to fifty years earlier. Alternately, selecting 'DMU' in the list of 'Labels to select a blog topic' will find all my posts about DMU (again, in reverse date-of-posting order). Finally, the Search Box in the page header (with the magnifying glass symbol) will find posts including any particular word or phrase.

Diesel Days 22-Jul-2018

Diesel Multiple Unit, Easter 2018 8-Apr-2018

Summer at Shackerstone 4-Aug-2017

DMU Days at the Battlefield Line 12-Jul-2017

Bank Holiday with Steam and Diesel 7-Jun-2017

The Heritage Railcar at Shackerstone, 2015 24-Jul-2015

The Battlefield Line, 2014 2-Apr-2014

Midweek at the Battlefield Line 9-Aug-2013

Battlefield Line 1940s Weekend (June 2013) 18-Jun-2013

Sunday Diesel 4-Mar-2013

Battlefield Line Modellers' Weekend 2012 29-May-2012

'Thomas' at the Battlefield Line 1-May-2012

The 'Mince Pie Flyer' 3-Jan-2012

Diesel Multiple Units 23-May-2010

Battlefield Line Mince Pie Specials 2009 3-Jan-2010

The Battlefield Line DMU Group 29-Apr-2007

Most of the above posts have links to albums of photographs which can be viewed or downloaded in various sizes. Alternately, you can go to a list of all my photograph collections on Flickr here and look for a particular picture.

[Post added 8-Apr-2018: Updated 14-Sep-2018]

Saturday, 7 April 2018

Monday, 2 April 2018

Railway Signalling in Britain: Part 8: Colour Light Signals

In part 4 of this series here, I discussed the illumination of semaphore signals by paraffin or electric lamps to make the indications visible to a driver at night.

But in conditions of poor visibility, such as fog or falling snow, it was realised that the lamp indications needed to be much brighter. Once the lamp indication is visible in all conditions, there is no need for the moving semaphore arm at all. This gave rise to Colour Light Signals which are becoming universal. The semaphore arm (and moving parts) are eliminated and, both by day and by night, the indication is given by various combinations of powerful coloured and white lights. Some cherished techniques from the semaphore era had to be re-designed and electric detection and electric locking largely replaced the mechanical counterparts.

Searchlight signals

The searchlight signal was an early form of colour light with only one lamp, always lit and projecting lens. Different colours were produced by filter pivoted between the lamp and the lens which produced one (more restrictive) colour when an electric solenoid was unenergised and a different colour when the filter was moved by energising the solenoid. The simplest arrangement produced a stop signal (displaying red or green aspect) or a distant signal (yellow or green aspect). Three aspects could be produced by using a polarised solenoid giving 'red' when unenergised, 'yellow' with one polarity applied to the solenoid and 'green' with the opposite polarity applied.

Front view of searchlight signal at Myo Haung, Burma.

Multiple aspect signals

In the U.K., searchlight signals gave way to designs with a separate lamp and lens for each colour where electromechanical relays controlled each lamp. These could be 2-aspect (like the London Underground signal illustrated below), 3-aspect or 4-aspect (described next).

A typical 4-aspect colour light from the 1960s. This is Derby P.S.B. signal DY187 on the Birmingham to Derby line

Click for larger view.

The picture above illustrates the typical features of multiple aspect colour light signals. The platform carrying the signal head is cantilevered to the right of the main post to improve sighting from a distance. For the benefit of the Signal and Telegraph Lineman, a simple handrail is provided around the platform and there is a permanent access ladder. The main post carries an identification plate with the unique signal number (usually first and last letters of the name, here 'DY' for 'Derby' and a number up to 3 digits long). This signal is on plain line with no diverging routes so the signal is arranged to operate automatically, as track circuits become occupied or cleared by the passage of trains. The white top part of the identification plate with a black horizontal bar indicates that this signal is not controlled by the signaller but is an 'Automatic'. However, a telephone is mounted lower down the main post which communicates with the Signaller. The two grey metal cabinets in the foreground are 'Location Cases' containing the necessary signalling relays, cable termination and power supplies. Two loudspeakers are mounted on the top of the smaller location case. This was the, rather crude, 'Staff Location System' of the period. Mobile phones, as we now understand them, were not available in the 1960s (1973 is accepted as the date of the first call on a Motorola mobile phone). Instead, the signaller could send one of four distinctive tones (one for each of three engineering disciplines plus a continuous tone for 'cancel') to the loudspeakers in an area where staff might be. As you can imagine, in built-up areas at night, use of this facility was not very popular with the neighbours.

In this type of multiple aspect colour light signal, four tungsten filament lamps are mounted vertically in line. When lit, each produces 'white' light (with a 'yellow' tinge). Colour filters in front of each lamp provide red, yellow or green light which is concentrated by a lens system on each lamp to project an intense beam towards the approaching trains when the lamp is lit. From the bottom, the four lamps produce red, yellow, green and, at the top, a second yellow. Four different 'aspects' or indications are given - red, yellow, green or 'double yellow' (where both yellow lamps are illuminated, but separated by the unlit 'green'aspect so that the driver can distinguish between 'single yellow - "prepare to stop at next signal" and 'double yellow' - "prepare to stop at next-but-one signal").

The most common repair would be 'replace failed lamp' but this type of low-voltage special bayonet-fitting lamp normally had two filaments.

Dual-filament lamp.

Failure of the main filament was detected by a lamp proving relay measuring the current flowing through the filament. Release of this relay upon failure of the main filament switched in the standby filament to keep the signal lit. The failure would be indicated to the Signaller (who, in the 1960s was still called a 'signalman') allowing the lineman to be alerted. Should the second filament fail or the power supply to the signal be lost, the signal would go 'dark'. In this case, the next signal in the rear would automatically be held at 'red' until relays proved that the failed signal should be showing a 'proceed' indication, in which case the signal in the rear would be allowed to display a 'single yellow' to keep trains moving whilst the problem was rectified.

There's more information about this type of signal and the electromechanical relay circuits which typically control them in the (as yet incomplete) series of posts on Princes End Electrical Controls starting here. The following description is taken from the post Princes End Electrical Controls (Part 4).

4-aspect signal head

Detail of 4-aspect signal head

Detail of 4-aspect signal head

Each lamp was fed from its own step-down transformer. The primary of each transformer (terminals 1 - 6 on the diagram above) was fed, via control relay contacts in the adjacent location case, with nominal 110 volts a.c.

The signal lamps were dual-filament low-voltage special bayonet-fitting type. Note that the 'Auxiliary' filament was fed from a lower voltage than the 'Main'. Each 'Main' filament was in series with a lamp proving relay mounted in the signal head ('ER1' to 'ER4'). If current was being drawn by the 'Main' filament, the appropriate lamp proving relay was energised and the 'Auxiliary' filament was disconnected. Release of the lamp proving relay connected the 'Auxiliary' filament via a normally closed ('back') contact.

Further contacts on the lamp proving relays were wired to indicate the status of the 'Main' filaments (terminals 7 - 9 on the diagram above). The contact circuit is drawn rather oddly but the effect is that the signal head presented a closed circuit between terminal 7 and terminal 8 (which was linked to terminal 9 externally) provided any of the relays 'ER1', 'ER2', 'ER3' were energised. The indication contact on 'ER4' (the second Yellow lamp used for the 'HH' 'Double Yellow' Aspect) could be shorted out by an external link when not used.

The signal head was a rectangular die cast box closed by a hinged door at the rear secured by a padlock. The front of the head had four apertures fitted with projecting sheet steel hoods to minimise the effect of overhead sunlight. Each aperture had a clear cast glass lens (the colour filtering was behind this lens). To project an intense beam visible at a distance, a Fresnel lens was used where the rear of the lens was shaped into a series of stepped rings. Because the Fresnel is so efficient at projecting light in a narrow beam, it could be difficult for a driver stopped close to the signal to confirm the aspect. In early signals of this type, a small second aspect was provided aligned to face a train waiting at the signal. This aspect was also provided with a small hood. Because of the shape of this hood, the device was often called the "pig's ear".

London Underground Signal Training facility, Bollo Lane, Acton: 2-aspect colour light signal with "pig's ear" aspects and 'theatre type' (multilamp) route indicator on the right capable of displaying '1' or '2'. Rail Gap Indicator on the left indicating section ahead discharged when lit.

However, by the 1960s, a simpler arrangement was in use. The section of cast glass Fresnel Lens between around 'four o'clock' and 'five o'clock' intentionally had a different profile, which deliberately scattered light towards a waiting train, rather than projecting it forward as part of the main beam.

The signal head was then mounted in a variety of ways, so as to give the driver the best possible 'sighting' of the signal. Straight tubular posts, brackets, massive cantilevers or gantry bridges were used, depending upon the geography.

Use of Light Emitting Diodes (LEDs)

To improve the reliability of signal lamps, replacement lamps were produced using multiple LEDs packaged as a plug-in replacement for a filament lamp.

Signal 'R101' on Platform 2 at Yangon, Burma. A multi-LED lamp has replaced the original filament lamp.

The availability of very high light output LEDs has led to various manufacturers producing a range of modern equipment, some of which is barely-recognisable as railway signals.

LED 4-aspect signal at Wolverhampton. Note the small, red indication projected sideways - the modern "pig's ear". Position light subsidiary aspect.

Related Posts on this Website

Railway Signalling in Britain (Index).

Princes End Electrical Controls (Part 1).

My Pictures

2-aspect colour light signal head.

Photographs may be selected, viewed or downloaded, in various sizes.

But in conditions of poor visibility, such as fog or falling snow, it was realised that the lamp indications needed to be much brighter. Once the lamp indication is visible in all conditions, there is no need for the moving semaphore arm at all. This gave rise to Colour Light Signals which are becoming universal. The semaphore arm (and moving parts) are eliminated and, both by day and by night, the indication is given by various combinations of powerful coloured and white lights. Some cherished techniques from the semaphore era had to be re-designed and electric detection and electric locking largely replaced the mechanical counterparts.

Searchlight signals

The searchlight signal was an early form of colour light with only one lamp, always lit and projecting lens. Different colours were produced by filter pivoted between the lamp and the lens which produced one (more restrictive) colour when an electric solenoid was unenergised and a different colour when the filter was moved by energising the solenoid. The simplest arrangement produced a stop signal (displaying red or green aspect) or a distant signal (yellow or green aspect). Three aspects could be produced by using a polarised solenoid giving 'red' when unenergised, 'yellow' with one polarity applied to the solenoid and 'green' with the opposite polarity applied.

Front view of searchlight signal at Myo Haung, Burma.

Multiple aspect signals

In the U.K., searchlight signals gave way to designs with a separate lamp and lens for each colour where electromechanical relays controlled each lamp. These could be 2-aspect (like the London Underground signal illustrated below), 3-aspect or 4-aspect (described next).

A typical 4-aspect colour light from the 1960s. This is Derby P.S.B. signal DY187 on the Birmingham to Derby line

Click for larger view.

The picture above illustrates the typical features of multiple aspect colour light signals. The platform carrying the signal head is cantilevered to the right of the main post to improve sighting from a distance. For the benefit of the Signal and Telegraph Lineman, a simple handrail is provided around the platform and there is a permanent access ladder. The main post carries an identification plate with the unique signal number (usually first and last letters of the name, here 'DY' for 'Derby' and a number up to 3 digits long). This signal is on plain line with no diverging routes so the signal is arranged to operate automatically, as track circuits become occupied or cleared by the passage of trains. The white top part of the identification plate with a black horizontal bar indicates that this signal is not controlled by the signaller but is an 'Automatic'. However, a telephone is mounted lower down the main post which communicates with the Signaller. The two grey metal cabinets in the foreground are 'Location Cases' containing the necessary signalling relays, cable termination and power supplies. Two loudspeakers are mounted on the top of the smaller location case. This was the, rather crude, 'Staff Location System' of the period. Mobile phones, as we now understand them, were not available in the 1960s (1973 is accepted as the date of the first call on a Motorola mobile phone). Instead, the signaller could send one of four distinctive tones (one for each of three engineering disciplines plus a continuous tone for 'cancel') to the loudspeakers in an area where staff might be. As you can imagine, in built-up areas at night, use of this facility was not very popular with the neighbours.

In this type of multiple aspect colour light signal, four tungsten filament lamps are mounted vertically in line. When lit, each produces 'white' light (with a 'yellow' tinge). Colour filters in front of each lamp provide red, yellow or green light which is concentrated by a lens system on each lamp to project an intense beam towards the approaching trains when the lamp is lit. From the bottom, the four lamps produce red, yellow, green and, at the top, a second yellow. Four different 'aspects' or indications are given - red, yellow, green or 'double yellow' (where both yellow lamps are illuminated, but separated by the unlit 'green'aspect so that the driver can distinguish between 'single yellow - "prepare to stop at next signal" and 'double yellow' - "prepare to stop at next-but-one signal").

The most common repair would be 'replace failed lamp' but this type of low-voltage special bayonet-fitting lamp normally had two filaments.

Dual-filament lamp.

Failure of the main filament was detected by a lamp proving relay measuring the current flowing through the filament. Release of this relay upon failure of the main filament switched in the standby filament to keep the signal lit. The failure would be indicated to the Signaller (who, in the 1960s was still called a 'signalman') allowing the lineman to be alerted. Should the second filament fail or the power supply to the signal be lost, the signal would go 'dark'. In this case, the next signal in the rear would automatically be held at 'red' until relays proved that the failed signal should be showing a 'proceed' indication, in which case the signal in the rear would be allowed to display a 'single yellow' to keep trains moving whilst the problem was rectified.

There's more information about this type of signal and the electromechanical relay circuits which typically control them in the (as yet incomplete) series of posts on Princes End Electrical Controls starting here. The following description is taken from the post Princes End Electrical Controls (Part 4).

4-aspect signal head

Detail of 4-aspect signal head

Detail of 4-aspect signal headEach lamp was fed from its own step-down transformer. The primary of each transformer (terminals 1 - 6 on the diagram above) was fed, via control relay contacts in the adjacent location case, with nominal 110 volts a.c.

The signal lamps were dual-filament low-voltage special bayonet-fitting type. Note that the 'Auxiliary' filament was fed from a lower voltage than the 'Main'. Each 'Main' filament was in series with a lamp proving relay mounted in the signal head ('ER1' to 'ER4'). If current was being drawn by the 'Main' filament, the appropriate lamp proving relay was energised and the 'Auxiliary' filament was disconnected. Release of the lamp proving relay connected the 'Auxiliary' filament via a normally closed ('back') contact.

Further contacts on the lamp proving relays were wired to indicate the status of the 'Main' filaments (terminals 7 - 9 on the diagram above). The contact circuit is drawn rather oddly but the effect is that the signal head presented a closed circuit between terminal 7 and terminal 8 (which was linked to terminal 9 externally) provided any of the relays 'ER1', 'ER2', 'ER3' were energised. The indication contact on 'ER4' (the second Yellow lamp used for the 'HH' 'Double Yellow' Aspect) could be shorted out by an external link when not used.

The signal head was a rectangular die cast box closed by a hinged door at the rear secured by a padlock. The front of the head had four apertures fitted with projecting sheet steel hoods to minimise the effect of overhead sunlight. Each aperture had a clear cast glass lens (the colour filtering was behind this lens). To project an intense beam visible at a distance, a Fresnel lens was used where the rear of the lens was shaped into a series of stepped rings. Because the Fresnel is so efficient at projecting light in a narrow beam, it could be difficult for a driver stopped close to the signal to confirm the aspect. In early signals of this type, a small second aspect was provided aligned to face a train waiting at the signal. This aspect was also provided with a small hood. Because of the shape of this hood, the device was often called the "pig's ear".

London Underground Signal Training facility, Bollo Lane, Acton: 2-aspect colour light signal with "pig's ear" aspects and 'theatre type' (multilamp) route indicator on the right capable of displaying '1' or '2'. Rail Gap Indicator on the left indicating section ahead discharged when lit.

However, by the 1960s, a simpler arrangement was in use. The section of cast glass Fresnel Lens between around 'four o'clock' and 'five o'clock' intentionally had a different profile, which deliberately scattered light towards a waiting train, rather than projecting it forward as part of the main beam.

The signal head was then mounted in a variety of ways, so as to give the driver the best possible 'sighting' of the signal. Straight tubular posts, brackets, massive cantilevers or gantry bridges were used, depending upon the geography.

Use of Light Emitting Diodes (LEDs)

To improve the reliability of signal lamps, replacement lamps were produced using multiple LEDs packaged as a plug-in replacement for a filament lamp.

Signal 'R101' on Platform 2 at Yangon, Burma. A multi-LED lamp has replaced the original filament lamp.

The availability of very high light output LEDs has led to various manufacturers producing a range of modern equipment, some of which is barely-recognisable as railway signals.

LED 4-aspect signal at Wolverhampton. Note the small, red indication projected sideways - the modern "pig's ear". Position light subsidiary aspect.

Related Posts on this Website

Railway Signalling in Britain (Index).

Princes End Electrical Controls (Part 1).

My Pictures

2-aspect colour light signal head.

Photographs may be selected, viewed or downloaded, in various sizes.

Sunday, 1 April 2018

Train movements at Yangon Central station (3)

Train movements on Monday 16th October 2017

There's a not-very-technical description of the day at Around Yangon.

There are various operational problems in the Yangon area. At Yangon Central Station, long distance trains use platforms 1, 2, and 3 on the north side of the station whilst local trains usually use platforms 4, 5, 6 and 7 on the south side. To the west of the station, double track carries both Circle Line suburban trains and long-distance services to Pyay. To the east of the station, there are two non-passenger roads (Down Goods, Up Goods/Shunting Neck East) and four roads for passenger trains (arranged Down Local, Up Local, Down Main, Up Main) as far as Pazundaung. The whole station area is currently controlled from Yangon Central Power Signal Box by a Westinghouse Style 'L' miniature lever frame. Details of a visit I made on 25th April 2014 are here.

The platforms are long enough to accommodate lengthy long-distance trains but, since local services are more frequent and shorter, a scissors crossover is provided halfway along platforms 5 and 6 and a second scissors halfway along platform 7 and Through Road 8. At present, platforms 7 and 8 each operate as two separate platforms, West and East.

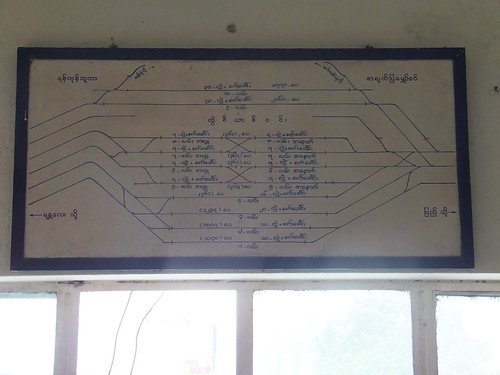

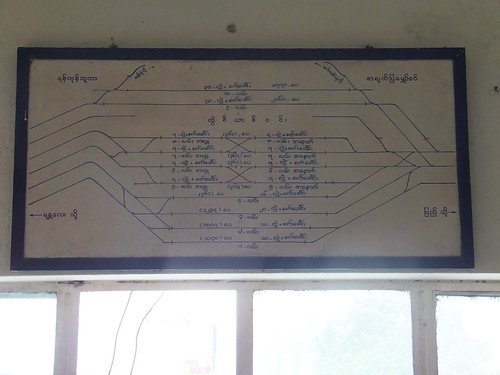

Yangon Central Power Signal Box: Simplified track diagram behind the supervisor's desk. Pazundaung is to the left and the double track west is on the right.

Click for larger version

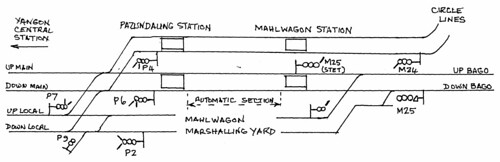

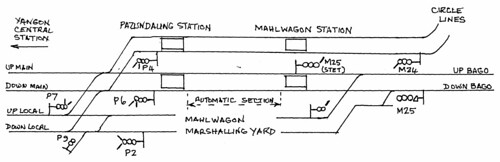

At Pazundaung a complex ‘flat crossing’ junction switches trains to and from the Circle Lines across the Up and Down Bago and Mandalay main lines as they pass from or to the local lines. This arrangement is shown in the diagram below and there's a little more information about Pazundaung and Mahlwagon here.

Myanma Railways: Simplified line diagram Pazundaung-Mahlwagon

Click for larger version

I was at the station from 10 o'clock in the morning for about an hour. I may not have included all movements as I was somewhat pre-occupied watching repairs to brakes on two trains. The first brake problem seems to have been a broken 'horn' on an 'ABC hose' coupling.

Repairing the vacuum hose ('ABS Hose') between two coaches on Platform 7: the alloy fitting with a broken horn which was replaced.

I'm not sure about the second problem. Initially, there appeared to be problems coupling the locomotive to the stock but then a mechanic was working on the brake rigging on one coach. The train finally left with the vacuum hoses 'split' between two coaches, so that only the front portion of the train had a working brake.

The 'bags' are 'split', leaving the rear of the train unbraked.

The movements I monitored are listed in the table below. Click on 'Photo' ref to view the associated picture. Use 'back button' (not the 'Back to photostream' button) to return to this post.

Related Posts on this Website

My first log of Train movements at Yangon Central station is in the post here. There's a later log here.

There are a number of posts describing Myanma Railways and my previous visits to Yangon Central station. You can find them all here or there's an Index (with links) here.

My Pictures

Railway pictures taken on 16th October 2017 referred to above form the collection Yangon Central Station (3).

All my pictures of Myanma Railways, including the Circle Line, are here.

Photographs may be selected, viewed or downloaded, in various sizes.

There's a not-very-technical description of the day at Around Yangon.

There are various operational problems in the Yangon area. At Yangon Central Station, long distance trains use platforms 1, 2, and 3 on the north side of the station whilst local trains usually use platforms 4, 5, 6 and 7 on the south side. To the west of the station, double track carries both Circle Line suburban trains and long-distance services to Pyay. To the east of the station, there are two non-passenger roads (Down Goods, Up Goods/Shunting Neck East) and four roads for passenger trains (arranged Down Local, Up Local, Down Main, Up Main) as far as Pazundaung. The whole station area is currently controlled from Yangon Central Power Signal Box by a Westinghouse Style 'L' miniature lever frame. Details of a visit I made on 25th April 2014 are here.

The platforms are long enough to accommodate lengthy long-distance trains but, since local services are more frequent and shorter, a scissors crossover is provided halfway along platforms 5 and 6 and a second scissors halfway along platform 7 and Through Road 8. At present, platforms 7 and 8 each operate as two separate platforms, West and East.

Yangon Central Power Signal Box: Simplified track diagram behind the supervisor's desk. Pazundaung is to the left and the double track west is on the right.

Click for larger version

At Pazundaung a complex ‘flat crossing’ junction switches trains to and from the Circle Lines across the Up and Down Bago and Mandalay main lines as they pass from or to the local lines. This arrangement is shown in the diagram below and there's a little more information about Pazundaung and Mahlwagon here.

Myanma Railways: Simplified line diagram Pazundaung-Mahlwagon

Click for larger version

I was at the station from 10 o'clock in the morning for about an hour. I may not have included all movements as I was somewhat pre-occupied watching repairs to brakes on two trains. The first brake problem seems to have been a broken 'horn' on an 'ABC hose' coupling.

Repairing the vacuum hose ('ABS Hose') between two coaches on Platform 7: the alloy fitting with a broken horn which was replaced.

I'm not sure about the second problem. Initially, there appeared to be problems coupling the locomotive to the stock but then a mechanic was working on the brake rigging on one coach. The train finally left with the vacuum hoses 'split' between two coaches, so that only the front portion of the train had a working brake.

The 'bags' are 'split', leaving the rear of the train unbraked.

The movements I monitored are listed in the table below. Click on 'Photo' ref to view the associated picture. Use 'back button' (not the 'Back to photostream' button) to return to this post.

| Time | Notes | Photo |

| 10:01 | Yangon Central Station, Monday 16-Oct-2017: DF.1240 on 6-coach train from the west having arrived in Platform 7 West. | 8671 |

| 10:04 | DF.1240 has moved ahead onto the Through Line (track 8). | 8673 |

| 10:07 | Having run-round its train in platform 7, DF.1240 on the left eases onto the stock. Note the approaching diesel railcar in the distance. | 8676 |

| 10:08 | Signal R56 is clear for DF.1240 to depart as RBE 3017 enters Platform 5. | 8680 |

| 10:13 | DF.1251 shut-down on train in Platform 6 West. | 8688 |

| 10:20 | Yangon Central Station, Monday 16-Oct-2017: DF.1240 finally sets off west. | 8698 |

| 10:22 | Stock in Platform 6 West (DF.1251) with DMU on 5 East. | 8701 |

| 10:25 | DF.1618 on arrival at Platform 7 East. | 8703 |

| 10:26 | DF.1618 runs forward onto Track 8. | 8704 |

| 10:30 | DF.1637 arriving in Platform 6 from West. | 8707 |

| 10:32 | Yangon Central Station, Monday 16-Oct-2017: East end of Platform 7. The signal is already cleared for the departure but there seems to be a problem 'hooking-on' DF.1618. Note the approaching train from the east on Track 8. | 8711 |

| 10:34 | Yangon Central Station, Monday 16-Oct-2017: A train formed from four single units including RBE 25119 leaves eastwards. | 8713 |

| 10:40 | The westbound train seen arriving at 10:32 departs from Platform 7 West. | 8721 |

| 10:40 | The delayed eastbound finally departs from Platform 7 East with DF.1618. | 8723 |

| 10:43 | DF.1243 arriving on Track 8 from the east. | 8725 |

| 10:44 | DF.1243 having arrived on Track 8 West (the Through Line) discharges passengers. | 8727 |

| 10:48 | DF.1243 on Platform 7 West, running round its train on 8 Through. Passengers boarded, but I left before the train departed eastwards. | 8729 |

Related Posts on this Website

My first log of Train movements at Yangon Central station is in the post here. There's a later log here.

There are a number of posts describing Myanma Railways and my previous visits to Yangon Central station. You can find them all here or there's an Index (with links) here.

My Pictures

Railway pictures taken on 16th October 2017 referred to above form the collection Yangon Central Station (3).

All my pictures of Myanma Railways, including the Circle Line, are here.

Photographs may be selected, viewed or downloaded, in various sizes.

Saturday, 31 March 2018

Train movements at Yangon Central station (2)

Yangon (formerly known as Rangoon) is no longer the capital city of Myanmar (that's Naypyitaw - my visit to the capital in 2013 is described in the post here and the following posts). None-the-less the most intensive working of suburban trains in the country is to be found around Yangon and the 7-platform Yangon Central Station.

I first wrote about Train movements at Yangon Central station in the post here. The station is controlled from a miniature lever Westinghouse power frame which I described in a post here.

All Myanmar's trains are operated by various diesel locomotives or railcars. Some vehicles are now quite elderly, although there are increasing numbers of new Chinese-built 2,000 h.p. diesel electric locomotives. There's an outline of the locomotive classes in the post Diesel Traction in Burma whilst diesel railcars and multiple-units are shown in Diesel Railcars in Burma. Both of these posts need updating (in particular the railcar post from 2013 which only hints, in the section 'Recent Developments', at the influx of second-hand re-gauged Japanese multiple units which have eliminated some locomotive-hauled workings around Yangon).

Yangon Central Station 1-Oct-2017: The tantalising view from my hotel room on the 21st floor of the Sule Shanri-La.

Train movements on Sunday 1st October 2017

There's a fairly non-technical description of the day here. Whilst I was on the roadbridge at the west end of Yangon Central Station (taking pictures before continuing to the station itself), a Japanese diesel multiple unit (RBE25109 leading but multipled to, I think, 8 coaches) departed heading west.

Second-hand Japanese DMU leaves platform 4 heading west with the post-war 'Burmese-style' station building in the rear.

My vantage point on the road bridge also showed DF.1622 (as I later confirmed) stood at the eastern end of four coaches (all in green and blue livery) standing at the eastern end of platform 6 for a long time. DF.1200.03 was standing in the west end of platform 7, attached to a bogie goods van. One of the hard-working 900 horse power units had arrived with a local train from the east in platform 7 East and it had soon uncoupled from its train and crossed onto the Through line, ready to run round its train.

Yangon Central Station: DF.1200.03 standing in the west end of platform 7, with bogie goods van and unidentified 900 horse power loco with a local train from the east in platform 7.

Another unidentified Bo-Bo-Bo arrived from the west with its train and headed to the unoccupied platform 5. I then continued my walk to the station, recording the Japanese signalling modernisation and taking pictures of train movements for around 90 minutes. The pictures taken on Sunday are in the collection Yangon Central Station (2).

Train movements on Monday 2nd October 2017

There's a fairly non-technical description of the day here. In the late afternoon, I walked to the station where I observed the train movements during the afternoon 'rush' for around an hour.

Yangon Central Station: View from platform 6, looking east.

Yangon Central Station: Building-up the 'knuckle' of an automatic coupler with electric welding in the carriage sidings to the south of the station.

Yangon Central Station: Building-up the 'knuckle' of an automatic coupler with electric welding in the carriage sidings to the south of the station.

Train movements on Tuesday 3rd October 2017

There's a fairly non-technical description of the day here. Whilst taking breakfast, I made a few notes about movements at the west end of the station:-

07:10 DF 1200-class (perhaps) in Red/cream arrives from the west with a goods van and 2 black (?) coaches, onto goods avoiding line.

07:25 Co-Co (brown/cream) from plat 1 to north siding.

07:30 4-car DMU green/cream arrives from west.

07:40 Bo Bo Bo red/blue arrives from east into 5 (?) with passenger train.

07:50 Bo Bo Bo red/blue arrives into 4 (?) from west with 10-coach train, all modern, pale green.

07:55 Bo Bo Bo red/blue LE off 07:40 arrival heads into north siding, stops, proceeds further then heads east on goods avoiding line.

I visited the station in the late afternoon when there is plenty of train movement.

Yangon Central Station: 3-Oct-2017: Three trains moving at the east end.

The movements I monitored are listed in the table below. Click on 'Photo' ref to view the associated picture. Use 'back button' (not the 'Back to photostream' button) to return to this post.

But don't ask about the coaches plastered with EU logos.

Yangon Central Station: 3-Oct-2017: Some elderly coaches are 'improved' by EU vinyls.

Related Posts on this Website

There are a number of posts describing Myanma Railways and my previous visits to Yangon Central station. You can find them all here or there's an Index (with links) here.

My Pictures

Railway pictures taken on 1st, 2nd and 3rd October referred to above form part of the collection Yangon Central Station (2).

All my pictures of Myanma Railways, including the Circle Line, are here.

Photographs may be selected, viewed or downloaded, in various sizes.

I first wrote about Train movements at Yangon Central station in the post here. The station is controlled from a miniature lever Westinghouse power frame which I described in a post here.

All Myanmar's trains are operated by various diesel locomotives or railcars. Some vehicles are now quite elderly, although there are increasing numbers of new Chinese-built 2,000 h.p. diesel electric locomotives. There's an outline of the locomotive classes in the post Diesel Traction in Burma whilst diesel railcars and multiple-units are shown in Diesel Railcars in Burma. Both of these posts need updating (in particular the railcar post from 2013 which only hints, in the section 'Recent Developments', at the influx of second-hand re-gauged Japanese multiple units which have eliminated some locomotive-hauled workings around Yangon).

Yangon Central Station 1-Oct-2017: The tantalising view from my hotel room on the 21st floor of the Sule Shanri-La.

Train movements on Sunday 1st October 2017

There's a fairly non-technical description of the day here. Whilst I was on the roadbridge at the west end of Yangon Central Station (taking pictures before continuing to the station itself), a Japanese diesel multiple unit (RBE25109 leading but multipled to, I think, 8 coaches) departed heading west.

Second-hand Japanese DMU leaves platform 4 heading west with the post-war 'Burmese-style' station building in the rear.

My vantage point on the road bridge also showed DF.1622 (as I later confirmed) stood at the eastern end of four coaches (all in green and blue livery) standing at the eastern end of platform 6 for a long time. DF.1200.03 was standing in the west end of platform 7, attached to a bogie goods van. One of the hard-working 900 horse power units had arrived with a local train from the east in platform 7 East and it had soon uncoupled from its train and crossed onto the Through line, ready to run round its train.

Yangon Central Station: DF.1200.03 standing in the west end of platform 7, with bogie goods van and unidentified 900 horse power loco with a local train from the east in platform 7.

Another unidentified Bo-Bo-Bo arrived from the west with its train and headed to the unoccupied platform 5. I then continued my walk to the station, recording the Japanese signalling modernisation and taking pictures of train movements for around 90 minutes. The pictures taken on Sunday are in the collection Yangon Central Station (2).

Train movements on Monday 2nd October 2017

There's a fairly non-technical description of the day here. In the late afternoon, I walked to the station where I observed the train movements during the afternoon 'rush' for around an hour.

Yangon Central Station: View from platform 6, looking east.

Yangon Central Station: Building-up the 'knuckle' of an automatic coupler with electric welding in the carriage sidings to the south of the station.

Yangon Central Station: Building-up the 'knuckle' of an automatic coupler with electric welding in the carriage sidings to the south of the station.

Train movements on Tuesday 3rd October 2017

There's a fairly non-technical description of the day here. Whilst taking breakfast, I made a few notes about movements at the west end of the station:-

07:10 DF 1200-class (perhaps) in Red/cream arrives from the west with a goods van and 2 black (?) coaches, onto goods avoiding line.

07:25 Co-Co (brown/cream) from plat 1 to north siding.

07:30 4-car DMU green/cream arrives from west.

07:40 Bo Bo Bo red/blue arrives from east into 5 (?) with passenger train.

07:50 Bo Bo Bo red/blue arrives into 4 (?) from west with 10-coach train, all modern, pale green.

07:55 Bo Bo Bo red/blue LE off 07:40 arrival heads into north siding, stops, proceeds further then heads east on goods avoiding line.

I visited the station in the late afternoon when there is plenty of train movement.

Yangon Central Station: 3-Oct-2017: Three trains moving at the east end.

The movements I monitored are listed in the table below. Click on 'Photo' ref to view the associated picture. Use 'back button' (not the 'Back to photostream' button) to return to this post.

| Time | Notes | Photo |

| 16:56 | DF.1238 arriving in platform 7 with a local from the east. | 6913 |

| 16:57 | DF.1238 uncouples and draws onto the 'Through' (road 8) prior to running round. | 6914 |

| 16:59 | DF.1220 crossing via scissors from plat 5 to plat 6, heading east. | 6916 |

| 17:04 | Eastbound departures in platforms 6 (DF.1220) and 7 (DF.1238), DMU leaving on Up Main in background. | 6924 |

| 17:05 | Fuzzy shot of Train Number 3, 17:00 departure 5 minutes late hauled by Chinese Bo-Bo-Bo. Train has Upper Class Sleeping, Upper Class, Ordinary Class and a Restaurent, due Mandalay 07:45 following morning. | 6925 |

| 17:06 | Bo-Bo-Bo departs from 6 as a Japanese DMU RBE25127 (with red headlamps) arrives on 8 (Through). | 6927 |

| 17:07 | Japanese DMU in 5 with DD522 Kawasaki station pilot, flat car for shunters and Bo-Bo-Bo DF1264 in 3. | 6928 |

| 17:07 | DF1238 leaving 7 as RBE 25127 awaits access to 7 | 6929 |

| 17:08 | DF2082 arriving with Down train (possibly train 32, 08:00 from Naypyitaw). | 6931 |

| 17:13 | Three trains moving at the east end (L-R) Japanese DMU departs east from 4, Japanese DMU also departs east from 5, whilst a Bo-Bo-Bo propels coaches into the carriage sidings. | 6937 |

| 17:16 | DF1264, with shunters flat car heads east from platform 3. | 6940 |

| 17:18 | DD522 takes empty coaches east. | 6942 |

| 17:25 | Yangon Central Station: 3-Oct-2017 Japanese DMU arriving in platform 5 from west. | 6947 |

| 17:26 | Bo-Bo-Bo about to leave platform 7 heading east with a passenger train. | 6948 |

| 17:28 | As a 900 hp arrives with 6 coaches with matching advertising logos (probably from Insein) a Bo-Bo-Bo heads east with a short train and many hangers-on. | 6950 |

| 17:28 | Yangon Central Station: 3-Oct-2017 DF1255 arriving in platform 7 from the west. A Japanese DMU stands in platform 6 West. | 6951 |

| 17:28 | Station Pilot propels empty stock into the carriage sidings. | 6952 |

| 17:32 | DF1246 arriving in platform 6 from the east with DF1255 in 7 waiting for the road. | 6959 |

| 17:34 | Yangon Central Station: 3-Oct-2017 DF1255 leaves platform 7 heading east. | 6963 |

| 17:41 | DF1248 runs round and couples-up ready to head back east at 17:43. | 6967 |

| 17:45 | DF2082 (which earlier brought in the train from Naypyitaw) appears light heading east on platform 5 and stops. | 6974 |

| 17:47 | DF1330 arrives with Train 90, 08:00 ex-Mawlamyine. | 6977 |

| 17:51 | DF1259 arrives in platform 7 from the west. | 6981 |

| 17:56 | DF2082 still awaits the road as an unidentified train departs eastwards. | 6987 |

But don't ask about the coaches plastered with EU logos.

Yangon Central Station: 3-Oct-2017: Some elderly coaches are 'improved' by EU vinyls.

Related Posts on this Website

There are a number of posts describing Myanma Railways and my previous visits to Yangon Central station. You can find them all here or there's an Index (with links) here.

My Pictures

Railway pictures taken on 1st, 2nd and 3rd October referred to above form part of the collection Yangon Central Station (2).

All my pictures of Myanma Railways, including the Circle Line, are here.

Photographs may be selected, viewed or downloaded, in various sizes.

Saturday, 24 March 2018

Class 08 User Manual

The English Electric 350 h.p. diesel-electric shunter is a rugged, useful locomotive. It became the 'Class 08' with variants classified 10, 11. These notes were specifically prepared back in 2002 for 13029 at Birmingham Railway Museum and details will vary on other locomotives. I have added a link to brief British rail training notes.

English Electric 350 h.p. diesel electric shunter 13029 (later Class 08) at Tyseley Locomotive Works. Around 1990, this was the first diesel I was passed to drive and was very handy for shunting early in the morning when the 'steamers' were still 'brewing-up'.

History

Class: 08/0

Built: BR 1958-1962.

Engine: English Electric 6-cyl 6KT of 400bhp (315kW).

Weight: 49 tonnes.

Brake force: 19 tonnes.

Maximum tractive effort: 35000lb (156kN).

Power/control equipment: English Electric Two EE505 traction motors. Double reduction gear drive.

BR Route availability: 5.

Maximum speed: 15 mph, except certain 20 mph.

Fuel: 668 gallons.

Pre-start checks

Check axlebox dipsticks for oil level and replenish if necessary. Oil coupling rods.

Open battery box on left side of locomotive and close battery switch. Open battery box on rightside of locomotive and close battery switch, additionally visually check the condition of the contacts on starter contactor.

Check main fuel tank gauge. There should be at least 50 gallons, to avoid sediment being drawn from the main tank. Enter cab and ensure handbrake applied. Check service tank fuel gauge. There should be at least 20 gallons, to avoid sediment being drawn into the engine fuel system. As necessary, operate the hand fuel transfer pump to replenish the service tank. Insert master key. Operate the hand pump on the rear wall of the cab for 30 - 45 seconds to pressurise the oil system.

Insert the master key and move to the non-locking 'EO' (Engine Only) position. Further operate the key to the non-locking 'start' position and hold in this position until the engine is firing correctly. Allow the key to return to the 'EO'position and then move it into the 'off' position, in which the battery will be re-charged and the main compressor will start. Wait until the main reservoir pressure (indicated on the duplex brake gauge) has reached 70 psi. Move the straight air brake application valve into the down (applied) position. Full brake pressure should be indicated on the duplex gauge.

The DSD is checked by placing the master direction controller in forward or backward, pressing the foot treadle and moving the driver's application valve for the straight air brake into the up (release) position. On the duplex gauge, the brake needle should fall to zero, indicating brake release. Release the DSD treadle and observe that, after a delay of a few seconds, the brake is automatically applied.

To release the brake after the test, place the driver's valve in the 'brake applied' position, depress the DSD treadle and move the driver's valve back to the release position.

To release the handbrake, partially apply the straight air brake then wind off the brake. Ensure the direction switch is set correctly for the intended movement, lookout to ensure it is safe to move, sound the horn and move to power controller into first notch. Pause at the first notch position and ensure that the motor contactor has energised (audible 'clump' from the control panel), then gently advance the power controller as necessary for the movement, checking the total generator amps as shown on the current meter.

Britsh Rail Mechanical Department, York training notes

These can be viewed, printed or downloaded here.

They comprise 9 pages:-

1. General Layout Diagram 200

2. Cooling Water System Description

3. Cooling Water System Diagram 201

4. Lubrication System Description

5. Lubrication System Diagram 202

6. Fuel System Description

7. Fuel System Diagram 203

8. Air and Vacuum System Description

9. Air and Vacuum System Diagram 204

English Electric 350 h.p. diesel electric shunter 13029 (later Class 08) at Tyseley Locomotive Works. Around 1990, this was the first diesel I was passed to drive and was very handy for shunting early in the morning when the 'steamers' were still 'brewing-up'.

History

Class: 08/0

Built: BR 1958-1962.

Engine: English Electric 6-cyl 6KT of 400bhp (315kW).

Weight: 49 tonnes.

Brake force: 19 tonnes.

Maximum tractive effort: 35000lb (156kN).

Power/control equipment: English Electric Two EE505 traction motors. Double reduction gear drive.

BR Route availability: 5.

Maximum speed: 15 mph, except certain 20 mph.

Fuel: 668 gallons.

Pre-start checks

Check axlebox dipsticks for oil level and replenish if necessary. Oil coupling rods.

Open battery box on left side of locomotive and close battery switch. Open battery box on rightside of locomotive and close battery switch, additionally visually check the condition of the contacts on starter contactor.

Check main fuel tank gauge. There should be at least 50 gallons, to avoid sediment being drawn from the main tank. Enter cab and ensure handbrake applied. Check service tank fuel gauge. There should be at least 20 gallons, to avoid sediment being drawn into the engine fuel system. As necessary, operate the hand fuel transfer pump to replenish the service tank. Insert master key. Operate the hand pump on the rear wall of the cab for 30 - 45 seconds to pressurise the oil system.

Insert the master key and move to the non-locking 'EO' (Engine Only) position. Further operate the key to the non-locking 'start' position and hold in this position until the engine is firing correctly. Allow the key to return to the 'EO'position and then move it into the 'off' position, in which the battery will be re-charged and the main compressor will start. Wait until the main reservoir pressure (indicated on the duplex brake gauge) has reached 70 psi. Move the straight air brake application valve into the down (applied) position. Full brake pressure should be indicated on the duplex gauge.

The DSD is checked by placing the master direction controller in forward or backward, pressing the foot treadle and moving the driver's application valve for the straight air brake into the up (release) position. On the duplex gauge, the brake needle should fall to zero, indicating brake release. Release the DSD treadle and observe that, after a delay of a few seconds, the brake is automatically applied.

To release the brake after the test, place the driver's valve in the 'brake applied' position, depress the DSD treadle and move the driver's valve back to the release position.

To release the handbrake, partially apply the straight air brake then wind off the brake. Ensure the direction switch is set correctly for the intended movement, lookout to ensure it is safe to move, sound the horn and move to power controller into first notch. Pause at the first notch position and ensure that the motor contactor has energised (audible 'clump' from the control panel), then gently advance the power controller as necessary for the movement, checking the total generator amps as shown on the current meter.

Britsh Rail Mechanical Department, York training notes

These can be viewed, printed or downloaded here.

They comprise 9 pages:-

1. General Layout Diagram 200

2. Cooling Water System Description

3. Cooling Water System Diagram 201

4. Lubrication System Description

5. Lubrication System Diagram 202

6. Fuel System Description

7. Fuel System Diagram 203

8. Air and Vacuum System Description

9. Air and Vacuum System Diagram 204

Passed Fireman

The Mutual Improvement Classes (MIC) of the old steam railways continue for today's preservation volunteers. This article, taken from notes of talks given by Jan in 2002, is one of a series about working on preserved railways. You can display them all by clicking here or see an index of article titles here.

Pete Waterman and Jan on the footplate of 8624 at Peak Rail in 2010 (Photo: Sheila Rayson).

The Passed Fireman is normally rostered as a fireman but, having become a Passed Fireman, he is available to act as Driver when required. The candidate for passed fireman will be expected to have had significant experience (the required experience depends upon the railway) of working around engines, moving through the grades of cleaner, passed cleaner and fireman. The safety procedures necessary on locomotives should have become second nature and the candidate should be relaxed and at ease on the footplate, whilst remaining alert and aware of everything going on. Monitoring the state of the boiler, correct use of the injectors/dampers/blower should all come readily, together with an easy familiarity with firing. This allows the candidate, once passed for driving, to adequately supervise his fireman and, where necessary, give assistance.

A driver has to be in control - of him or herself, the fireman, the locomotive and the train. A good driver radiates quiet confidence which comes from mastery of driving and firing and a thorough understanding of the design and operation of all aspects of the locomotive.

This is quite a task which is why, before the Second World War, a railwayman could spend twenty years or more on the footplate becoming thoroughly conversant with everything he might need to know. In present day preservation, promotion to driver is likely to come much earlier. A professional railwayman will have spent every working day working on locomotives - a volunteer, however keen, is unlikely to have spent more than one or two days a week, if that. Accordingly, you need to compensate for the relative lack of experience partly by seeking a thorough understanding of the engineering theory underlying locomotive design and partly by consciously avoiding the complacency which familiarity may encourage. Safety comes through recognition of your own relative inexperience.

Locomotive Preparation and daily examination

On taking charge of a locomotive, you must ensure that the locomotive is in a safe condition - mid gear, cylinder drain cocks open, handbrake hard on, regulator closed and that the gauge frames are in the working position with sufficient water showing in the glass. You must make yourself responsible for the safety of the booked fireman and any rostered preparation crew working on the engine. Ensure that they report to you on arrival and do not leave for other tasks without your permission. You must set a good example for them to copy and not allow yourself to slip into sloppy or dangerous practices.

Boiler management during preparation is crucial and the driver must be able to supervise his fireman adequately, giving help and advice so that the fireman becomes more confident and more skilled. Effective preparation of the smokebox (char removed and door airtight), ashpan (ash removed and dampers working properly) and fire (clinker removed and firebars in good order) is vital to ensure complete combustion of every shovelful.

Although drivers will frequently allow their fireman or preparation staff to oil round the locomotive to gain experience, the daily examination is something a driver will want to perform himself. Be methodical, work round the engine checking for anything which may later become a problem. Examples are fractures, cracks, unexpected or unusual wear, damaged, bent or misplaced components, missing locknuts, cotters or split pins and, particularly, displaced spring hangers or broken springs. Check for any leaks (steam, water or oil). As far as oiling is concerned, ensure that any missing corks are replaced and check the condition of a sample of the trimmings. If possible, carry a small selection of corks so that any found missing or damaged can be replaced without the need to make a special journey. If a mechanical lubricator is fitted, ensure that this is filled with the correct grade of oil has been used and, when a priming handwheel is fitted, ensure that this has been operated so as to fill the oil delivery lines. Where a sight feed or hydrostatic lubricator is fitted, this must be carefully filled with clean oil, ensuring that it really is full.

Traction and Adhesion

We walk by trying to slide a foot backwards along the ground. Normally, there is sufficient friction between sole of the shoe and the ground to prevent sliding. Instead, the foot stays where it is but the body is levered forwards. However, if we try the same thing on ice, the friction between shoe and ice is much lower and the usual result is that the foot slides backwards. We can walk on ice only by deliberately reducing the sliding force generated by the muscles so that it is too small to break down the reduced level of friction between shoe and ice.

Moving a locomotive is a bit like walking on ice. A locomotive moves by applying torque (a turning force) to the driven axles. At the wheel tyre, this force attempts to slide the wheel on the rail. Under suitable conditions, sliding does not occur but instead the torque levers the engine forward so that a new part of the wheel tyre is in contact with the rail and the process continues. The force applied at the rail/wheel interface is proportional to the total area of the pistons on which the steam operates, the pressure of steam employed and inversely proportional to the diameter of the driven wheels. This force is usually termed the Tractive Effort of the locomotive, commonly expressed in 'pounds of force'.

Examined microscopically, neither the railhead nor the wheel tyre are smooth. For successful motion, there must be sufficient friction on the small area of contact between the tyres of the driven wheels and the rail for the engine to lever itself forward. The total friction is proportional to the number of driven wheels and the weight bearing down on each wheel - up to 10 tons or more on a large engine. If the torque applied to the wheels is progressively increased, it eventually exceeds the friction between wheels and rail and, at this point, wheelslip occurs. It is important that the driver reacts promptly to wheelslip to prevent damage to the engine by temporarily closing (or partly closing) the regulator. Remember that the response to closing the regulator will not be instant. The steam already in the main steam pipe, superheater elements (if fitted) and the steam chests will continue to drive the wheels for a time. Where a locomotive is fitted with a steam brake, some drivers will rub the brake to inhibit the slip and then reduce the braking effort as the slip dies away.

A cautious driver will avoid slips on starting by gradually opening the regulator until there is sufficient power to start the train moving. Once the train is rolling, power can be further increased to accelerate the train away. Variations in boiler pressure will clearly affect the power available - a larger regulator opening will be needed if the boiler pressure is lower than normal.

Clearly, the heavier the train or the steeper the gradient, the more power must be applied before the train moves away and the driver has to juggle the power to provide sufficient force to move without slipping. When the load is at the limit of adhesion, brief intermittent slipping may be inevitable.

The actual friction will vary according to the condition of the wheel tyres and the condition of the railhead. Rain has a profound effect and a slight drizzle will drastically reduce the friction between rail and wheel. During heavy rain, friction will tend to improve as the rain scours away the oil and grease which is normally present. Curvature of the track is also a factor. On a curve, the flanges of the driven wheels pressing against the outer rail may locally increase the friction available, but the rolling resistance of the train on the curve will also increase, requiring more power in any case. When moving through pointwork, values of rail/wheel friction on the driven wheels will fluctuate as the wheels pass through switch rails, check rails and crossings.

Engine weight diagrams show the theoretical static loads carried on each axle. The weight carried by the driving wheels determines the friction between tyre and rail and thus the amount of power which can be absorbed before wheelslip occurs. But, in traffic, the actual weight on each axle can vary quite widely, particularly if an engine has been roughly handled or spring characteristics are not ideal. Some locomotive designs include compensating beams to share the load between a number of axles but many types have independent suspension on each wheel.

Another factor to consider is weight transfer. Different designs and wheel arrangements have varying characteristics but many locomotives tend to rise up at the front when starting away with a load on the rear drawbar. This alters the distribution of load between the various axles. In a 'Pacific' the effect is unhelpful as it tends to 'unload' the coupled wheels and increase the weight on the carrying wheels at the rear, reducing the weight available for adhesion and thus the amount of power which can be applied without slipping. Any irregularities or undulations in the track such as a 'dropped' rail joint or pointwork in need of packing will also encourage this weight transfer effect, increasing the likelihood of slipping.

Although slipping is usually associated with starting a train away, high speed slips can occur, for instance when a locomotive running near the limit of adhesion hits a bad rail joint; a driver must be constantly prepared to take corrective action.

Braking

There's an old railway maxim 'Any fool can start a train, but it takes a driver to stop one'. As a fireman, you will have studied braking systems, but, in preparation for driving, you should review your understanding. When you're on a greasy rail with a few hundred tons on the drawhook is no time to realise that you've insufficient brake power! You must ensure that you are fully conversant with the various types of brakes, the method of testing them and the problems that you may encounter day-to-day. Remember, as a driver, there usually no-one to turn to for advice and you will have to decide how to tackle any situation.

Timekeeping and Economy

Drivers can be divided into three types, according to their response to a train which is delayed in starting. One type takes the view 'oh well, we're late already, a few minutes more won't hurt' and allows the delay to increase. The second type carefully maintains the scheduled sectional times but arrives as many minutes late as departure was delayed. The third type goes all out to recover the lost time. The third type of driver produces the most stirring runs and is the most widely reported but the second type of driver is usually the most economical. There is normally a price to pay in working locomotives to the limit: efficiency often deteriorates badly and water and coal consumption can be badly hit. Maintenance costs can also rise drastically due to increased wear. The expert driver will balance all these factors and will rarely, if ever 'thrash' an engine. A good driver will take pride in working to the schedule he is given in an economical manner and without working the engine harder than necessary. Drivers must thus be familiar with the factors which affect economy and must be able to choose the best method of working with any engine in any situation.

Boiler management crucially affects economy and the driver must supervise his fireman, giving help and advice where needed. Dampers and secondary air must be carefully regulated and the rate of firing adjusted to the needs of the job. The locomotive should never be allowed to blow-off as this represents a loss of coal and water. Boilers are usually most efficient when operated near their working pressure and the chosen pressure should be maintained as constant as possible for best economy. Good results on the road are often obtained by running the boiler at a constant rate of steaming. As the gear is linked-up, speed rises and when the cut-off is lengthened for hill climbing (using more steam per stroke) speed is allowed to fall, keeping demand for steam more-or-less constant.

Economy is best achieved by using steam expansively in the cylinders. When starting away, a locomotive might operate at a cut-off of, say, 75%. This means that the piston will complete 75% of its stroke before the steam supply is shut off by the steam valve valve. The volume of steam in the cylinder is then expanded by 1/3 as the piston completes its stroke before being exhausted through the blast pipe to the chimney. Once under way, the cut-off might be brought back to, say, 50%. This means that the steam valve will now cut off the steam supply when the piston has completed only half its stroke. The half cylinder-full of steam will expand itself to fill the cylinder - expansion to twice the original volume - before the steam valve opens to exhaust the used steam. As steam is expanded in the cylinder, it continues to do work in pushing against the piston and the steam is cooled. The exhaust steam is thus cooler when an engine is 'linked up' to an earlier cut-off than in full gear and this means that more work is extracted from the steam. In addition, when linked-up, less live steam is drawn from the boiler on each stroke, allowing the locomotive speed to increase without demanding a higher rate of steaming from the boiler. What must be avoided is expanding steam so much that the temperature falls sufficiently for the steam to condense into water. This not only chills the cylinder Casting (wasting syteam on the next stroke in warming the cylinder again) but leaves water in the cylinder which may not be swept from the cylinder during exhaust as more fluid steam would be. The advantage of using superheated steam is that its initial temperature is higher than saturated steam at the same pressure and so a greater expansion ratio may be used without risk of condensation in the cylinder.

When an engine is in full gear, the travel of the steam valve is at its maximum and so the maximum possible openings are obtained during admission and exhaust. As the gear is linked-up, the travel of the steam valve is shortened so that steam is cut off earlier in the piston stroke. But this means that the maximum possible opening no longer achieved and making complete exhaust of the used steam more difficult. This tends to require more live steam to counteract the back pressure produced by the exhaust steam as it is forced out through the restricted exhaust port, impairing the economy of the engine. Valve travels on slide-valved engines were in the order of 4 - 5 inches. Because of the design of the unbalanced steam valve, shorter valve travel meant less work was wasted in moving the valve against friction. Balanced slide valves allowed larger designs to be produced but these gave way to balanced piston valves where much less work was wasted, allowing the advantages of long-lap, long-travel valves to be exploited.

Pete Waterman and Jan on the footplate of 8624 at Peak Rail in 2010 (Photo: Sheila Rayson).

The Passed Fireman is normally rostered as a fireman but, having become a Passed Fireman, he is available to act as Driver when required. The candidate for passed fireman will be expected to have had significant experience (the required experience depends upon the railway) of working around engines, moving through the grades of cleaner, passed cleaner and fireman. The safety procedures necessary on locomotives should have become second nature and the candidate should be relaxed and at ease on the footplate, whilst remaining alert and aware of everything going on. Monitoring the state of the boiler, correct use of the injectors/dampers/blower should all come readily, together with an easy familiarity with firing. This allows the candidate, once passed for driving, to adequately supervise his fireman and, where necessary, give assistance.

A driver has to be in control - of him or herself, the fireman, the locomotive and the train. A good driver radiates quiet confidence which comes from mastery of driving and firing and a thorough understanding of the design and operation of all aspects of the locomotive.

This is quite a task which is why, before the Second World War, a railwayman could spend twenty years or more on the footplate becoming thoroughly conversant with everything he might need to know. In present day preservation, promotion to driver is likely to come much earlier. A professional railwayman will have spent every working day working on locomotives - a volunteer, however keen, is unlikely to have spent more than one or two days a week, if that. Accordingly, you need to compensate for the relative lack of experience partly by seeking a thorough understanding of the engineering theory underlying locomotive design and partly by consciously avoiding the complacency which familiarity may encourage. Safety comes through recognition of your own relative inexperience.

Locomotive Preparation and daily examination

On taking charge of a locomotive, you must ensure that the locomotive is in a safe condition - mid gear, cylinder drain cocks open, handbrake hard on, regulator closed and that the gauge frames are in the working position with sufficient water showing in the glass. You must make yourself responsible for the safety of the booked fireman and any rostered preparation crew working on the engine. Ensure that they report to you on arrival and do not leave for other tasks without your permission. You must set a good example for them to copy and not allow yourself to slip into sloppy or dangerous practices.

Boiler management during preparation is crucial and the driver must be able to supervise his fireman adequately, giving help and advice so that the fireman becomes more confident and more skilled. Effective preparation of the smokebox (char removed and door airtight), ashpan (ash removed and dampers working properly) and fire (clinker removed and firebars in good order) is vital to ensure complete combustion of every shovelful.

Although drivers will frequently allow their fireman or preparation staff to oil round the locomotive to gain experience, the daily examination is something a driver will want to perform himself. Be methodical, work round the engine checking for anything which may later become a problem. Examples are fractures, cracks, unexpected or unusual wear, damaged, bent or misplaced components, missing locknuts, cotters or split pins and, particularly, displaced spring hangers or broken springs. Check for any leaks (steam, water or oil). As far as oiling is concerned, ensure that any missing corks are replaced and check the condition of a sample of the trimmings. If possible, carry a small selection of corks so that any found missing or damaged can be replaced without the need to make a special journey. If a mechanical lubricator is fitted, ensure that this is filled with the correct grade of oil has been used and, when a priming handwheel is fitted, ensure that this has been operated so as to fill the oil delivery lines. Where a sight feed or hydrostatic lubricator is fitted, this must be carefully filled with clean oil, ensuring that it really is full.

Traction and Adhesion

We walk by trying to slide a foot backwards along the ground. Normally, there is sufficient friction between sole of the shoe and the ground to prevent sliding. Instead, the foot stays where it is but the body is levered forwards. However, if we try the same thing on ice, the friction between shoe and ice is much lower and the usual result is that the foot slides backwards. We can walk on ice only by deliberately reducing the sliding force generated by the muscles so that it is too small to break down the reduced level of friction between shoe and ice.

Moving a locomotive is a bit like walking on ice. A locomotive moves by applying torque (a turning force) to the driven axles. At the wheel tyre, this force attempts to slide the wheel on the rail. Under suitable conditions, sliding does not occur but instead the torque levers the engine forward so that a new part of the wheel tyre is in contact with the rail and the process continues. The force applied at the rail/wheel interface is proportional to the total area of the pistons on which the steam operates, the pressure of steam employed and inversely proportional to the diameter of the driven wheels. This force is usually termed the Tractive Effort of the locomotive, commonly expressed in 'pounds of force'.

Examined microscopically, neither the railhead nor the wheel tyre are smooth. For successful motion, there must be sufficient friction on the small area of contact between the tyres of the driven wheels and the rail for the engine to lever itself forward. The total friction is proportional to the number of driven wheels and the weight bearing down on each wheel - up to 10 tons or more on a large engine. If the torque applied to the wheels is progressively increased, it eventually exceeds the friction between wheels and rail and, at this point, wheelslip occurs. It is important that the driver reacts promptly to wheelslip to prevent damage to the engine by temporarily closing (or partly closing) the regulator. Remember that the response to closing the regulator will not be instant. The steam already in the main steam pipe, superheater elements (if fitted) and the steam chests will continue to drive the wheels for a time. Where a locomotive is fitted with a steam brake, some drivers will rub the brake to inhibit the slip and then reduce the braking effort as the slip dies away.

A cautious driver will avoid slips on starting by gradually opening the regulator until there is sufficient power to start the train moving. Once the train is rolling, power can be further increased to accelerate the train away. Variations in boiler pressure will clearly affect the power available - a larger regulator opening will be needed if the boiler pressure is lower than normal.

Clearly, the heavier the train or the steeper the gradient, the more power must be applied before the train moves away and the driver has to juggle the power to provide sufficient force to move without slipping. When the load is at the limit of adhesion, brief intermittent slipping may be inevitable.

The actual friction will vary according to the condition of the wheel tyres and the condition of the railhead. Rain has a profound effect and a slight drizzle will drastically reduce the friction between rail and wheel. During heavy rain, friction will tend to improve as the rain scours away the oil and grease which is normally present. Curvature of the track is also a factor. On a curve, the flanges of the driven wheels pressing against the outer rail may locally increase the friction available, but the rolling resistance of the train on the curve will also increase, requiring more power in any case. When moving through pointwork, values of rail/wheel friction on the driven wheels will fluctuate as the wheels pass through switch rails, check rails and crossings.

Engine weight diagrams show the theoretical static loads carried on each axle. The weight carried by the driving wheels determines the friction between tyre and rail and thus the amount of power which can be absorbed before wheelslip occurs. But, in traffic, the actual weight on each axle can vary quite widely, particularly if an engine has been roughly handled or spring characteristics are not ideal. Some locomotive designs include compensating beams to share the load between a number of axles but many types have independent suspension on each wheel.

Another factor to consider is weight transfer. Different designs and wheel arrangements have varying characteristics but many locomotives tend to rise up at the front when starting away with a load on the rear drawbar. This alters the distribution of load between the various axles. In a 'Pacific' the effect is unhelpful as it tends to 'unload' the coupled wheels and increase the weight on the carrying wheels at the rear, reducing the weight available for adhesion and thus the amount of power which can be applied without slipping. Any irregularities or undulations in the track such as a 'dropped' rail joint or pointwork in need of packing will also encourage this weight transfer effect, increasing the likelihood of slipping.

Although slipping is usually associated with starting a train away, high speed slips can occur, for instance when a locomotive running near the limit of adhesion hits a bad rail joint; a driver must be constantly prepared to take corrective action.

Braking

There's an old railway maxim 'Any fool can start a train, but it takes a driver to stop one'. As a fireman, you will have studied braking systems, but, in preparation for driving, you should review your understanding. When you're on a greasy rail with a few hundred tons on the drawhook is no time to realise that you've insufficient brake power! You must ensure that you are fully conversant with the various types of brakes, the method of testing them and the problems that you may encounter day-to-day. Remember, as a driver, there usually no-one to turn to for advice and you will have to decide how to tackle any situation.

Timekeeping and Economy

Drivers can be divided into three types, according to their response to a train which is delayed in starting. One type takes the view 'oh well, we're late already, a few minutes more won't hurt' and allows the delay to increase. The second type carefully maintains the scheduled sectional times but arrives as many minutes late as departure was delayed. The third type goes all out to recover the lost time. The third type of driver produces the most stirring runs and is the most widely reported but the second type of driver is usually the most economical. There is normally a price to pay in working locomotives to the limit: efficiency often deteriorates badly and water and coal consumption can be badly hit. Maintenance costs can also rise drastically due to increased wear. The expert driver will balance all these factors and will rarely, if ever 'thrash' an engine. A good driver will take pride in working to the schedule he is given in an economical manner and without working the engine harder than necessary. Drivers must thus be familiar with the factors which affect economy and must be able to choose the best method of working with any engine in any situation.

Boiler management crucially affects economy and the driver must supervise his fireman, giving help and advice where needed. Dampers and secondary air must be carefully regulated and the rate of firing adjusted to the needs of the job. The locomotive should never be allowed to blow-off as this represents a loss of coal and water. Boilers are usually most efficient when operated near their working pressure and the chosen pressure should be maintained as constant as possible for best economy. Good results on the road are often obtained by running the boiler at a constant rate of steaming. As the gear is linked-up, speed rises and when the cut-off is lengthened for hill climbing (using more steam per stroke) speed is allowed to fall, keeping demand for steam more-or-less constant.